Underground pipe column of gas well

A technology for downhole pipe strings and gas wells, which is applied in the direction of wellbore/well components, drill pipes, casings, etc., which can solve the problems of large ground space occupation, high cost, and easy blockage, etc., to reduce pollution, save economic costs, reduce The effect of occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

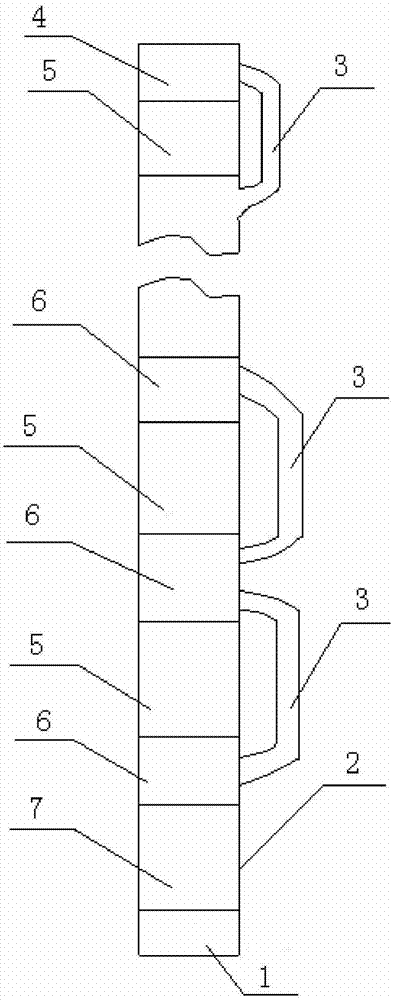

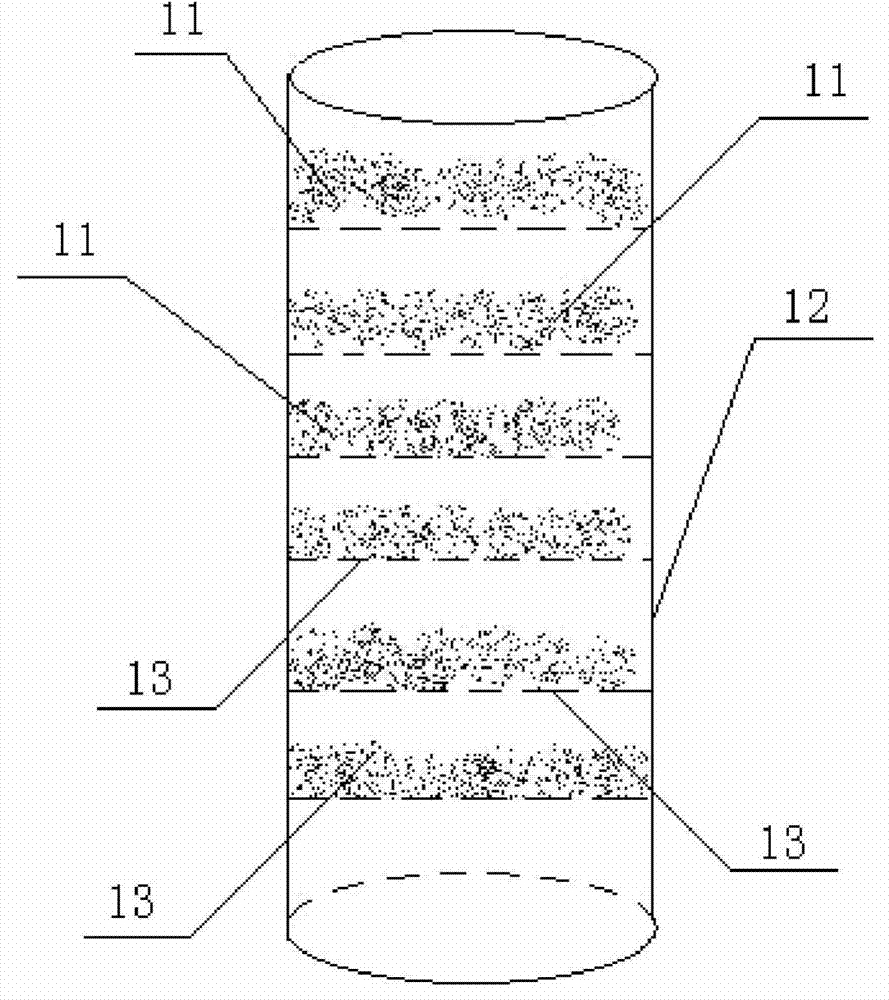

[0026] Such as figure 1 As shown, the present invention includes a gas pipeline 2, a solid impurity removal device 7, and a plurality of gas filter devices 5. The two ends of the gas pipeline 2 are respectively provided with an air inlet 1 and an air outlet 4, and the gas passes through the air inlet after mining. 1 into the pipe string, and then output to the ground through the air outlet 4. The solid impurity removal device 7 is fixedly installed at one end of the gas pipeline 2 close to the air inlet 1, and the number of the solid impurity removal device 7 can be installed and set according to the transportation requirements, and can be stacked if the transportation distance is long A plurality of solid impurity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com