Process for producing case or accessories of precious metal wristwatch

A production process and precious metal technology, applied in the direction of electrolysis, electroforming, etc., can solve the problems of unsatisfactory dimensional accuracy, watch case manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

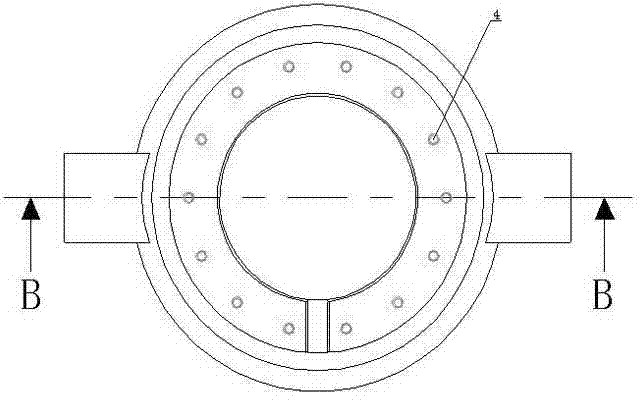

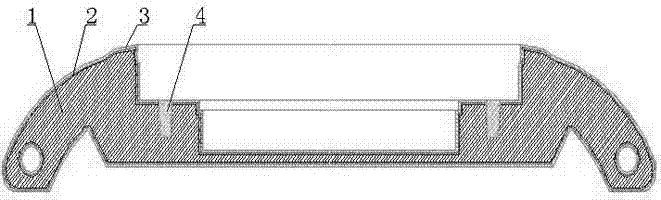

[0021] Embodiment one: if Figure 1~3 As shown, a production process of a precious metal watch case or trim of the present invention comprises a mold type 1, a copper electroplating layer 2 and a precious metal watch case layer 3, and the material of the mold type 1 is No. 3 zinc alloy, and the mold type The first is obtained by die-casting; the copper electroplating layer 2 is obtained by electroplating a certain thickness of copper on the model 1; the precious metal watch case 3 is obtained by electroforming a certain thickness of precious metal on the copper electroplating layer. It is hard solid gold; the discharge hole 4 is a hole drilled after electroplating copper and precious metals; the mold type 1 (the material is zinc alloy) and the copper electroplating layer 2 are formed by adding hydrochloric acid with a mass fraction of 37% and Heating to the boiling point for chemical reaction and melting, the zinc alloy is completely dissolved in hydrochloric acid, and dischar...

Embodiment 2

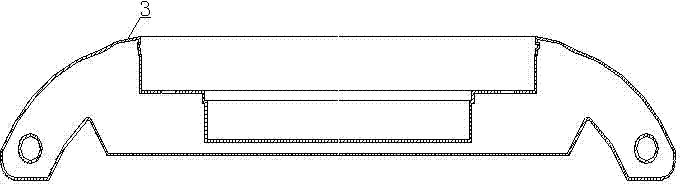

[0028] Embodiment two: if Figure 4~6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the watch case 3 is provided with a reinforcing tube 5; the discharge hole 4 is opened on the side wall of the reinforcing tube 5 .

[0029] The more specific production steps are: first die-cast the No. 3 zinc alloy to make the mold, put the mold into the CuSO4 electroplating solution with a mass fraction of 85% for electroplating, the electroplating working temperature is 60 ° C ~ 70 ° C, the current density 100A / cm 2 , the electroplating time is 3 minutes; after taking it out of the CuSO4 electroplating solution, wash it in clean water for 1 minute, and then put it into the electroforming tank for electroforming. 2 , the electroforming time is 2 minutes; take it out of the CuSO4 electroplating solution and wash it in clean water for 1 minute, and then soak it with 37% hydrochloric acid at a temperature of 60°C after drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com