Fiber hairbrush scraper

A brush and scraper technology, which is applied in the field of rapid prototyping, can solve the problems of increasing the friction between the scraper and the workpiece, reducing the service life of the scraper, and being prone to wear and tear, avoiding bending deformation or shaking, increasing the service life, and a simple production method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0047] This embodiment is a carbon fiber brush scraper in the radar shock absorber ( Figure 9 ) and semiconductor laser microchannel heat sink ( Figure 10 ) application in the manufacturing process.

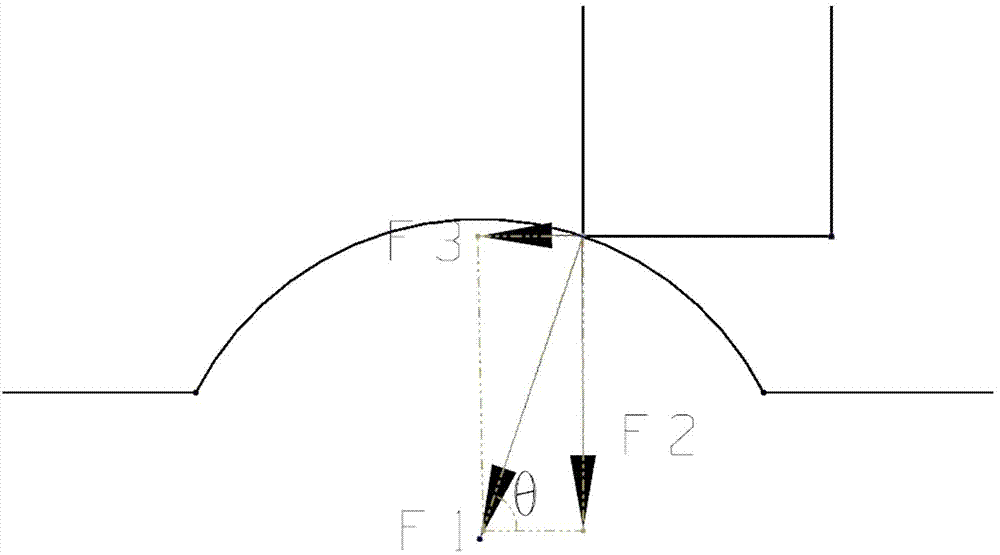

[0048] In this embodiment, the interior of the radar shock absorber is a grid structure, and the size of the fine structure in the grid is small, and the smallest structure size is 0.15 mm. The internal channel of the semiconductor laser microchannel heat sink is an open circulation channel, and the wall thickness between adjacent channels is only 0.2mm. Due to the small size of these structures, the strength is low. If a traditional scraper is used, the liquid droplet after melting the metal powder has a large surface expansion force, which is prone to spheroidization. When using a traditional scraper, when the scraper passes through these places, it will rigidly collide with the hemispherical protrusions. Due to the large force during the collision, these fine structures wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com