Low molecular weight chondroitin sulfate preparation method

A chondroitin sulfate, low molecular weight technology, applied in fermentation and other directions, can solve the problems of unsuitability for large-scale production, wide product molecular weight distribution, high equipment requirements, maintain integrity and biological activity, reduce the difficulty of complex enzymatic hydrolysis, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

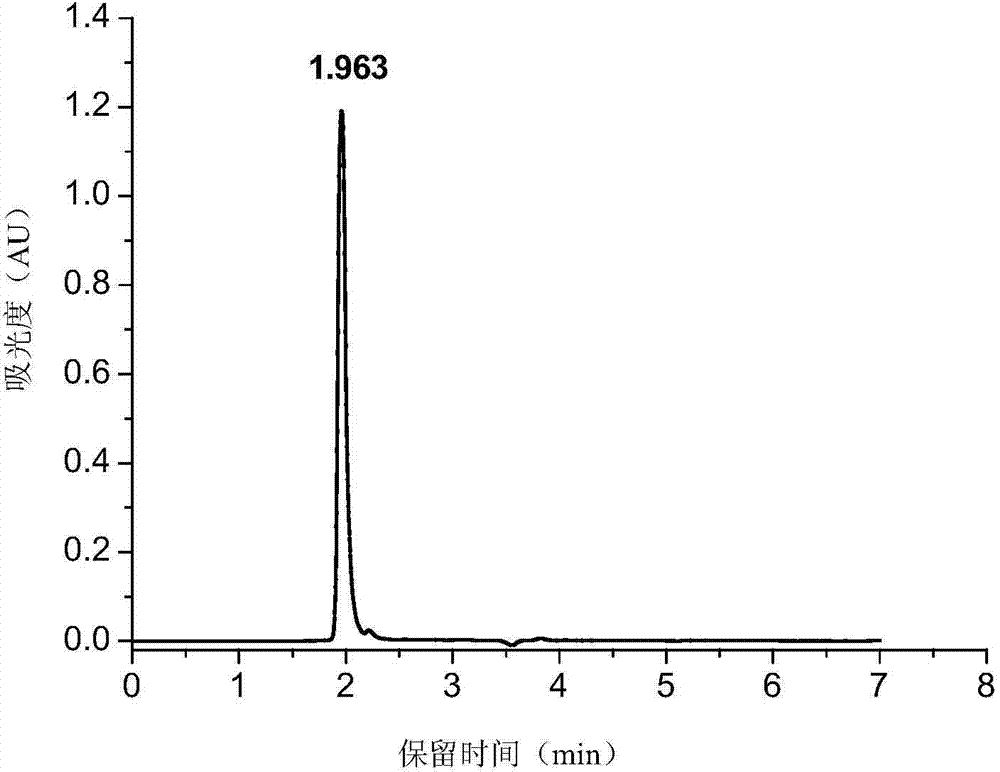

Embodiment 1

[0040] Take fresh sturgeon spine tissue and place it in a boiling water bath for 1 hour, remove muscle, fat and other attachments on the surface of the spine, soak in petroleum ether, wash with alcohol, dry at 70°C, pulverize with a grinder, and weigh for later use. Weigh 30g of cartilage granules, add 4% NaOH solution according to the ratio of material to liquid 1:5, and stir at 45°C for 30min. After adjusting the pH to 7.0 with hydrochloric acid, add malic acid until the pH is 3.0, add pepsin with 0.8% cartilage mass, and stir at 37°C for 4 hours, during which the pH is adjusted to be stable at 3.0. Adjust the pH to 5.0, add papain and cellulase with a mass of 3% cartilage at a ratio of 1:1, stir at 55°C for 4 hours, and adjust the pH to stabilize at 5.0 during this period. Add 0.5% activated carbon in the volume of the solution, stir at 80°C for 30 minutes, cool and filter to obtain the enzymolysis solution. Adjust the pH to 6.0, adjust the NaCl concentration to 0.25mol / L,...

Embodiment 2

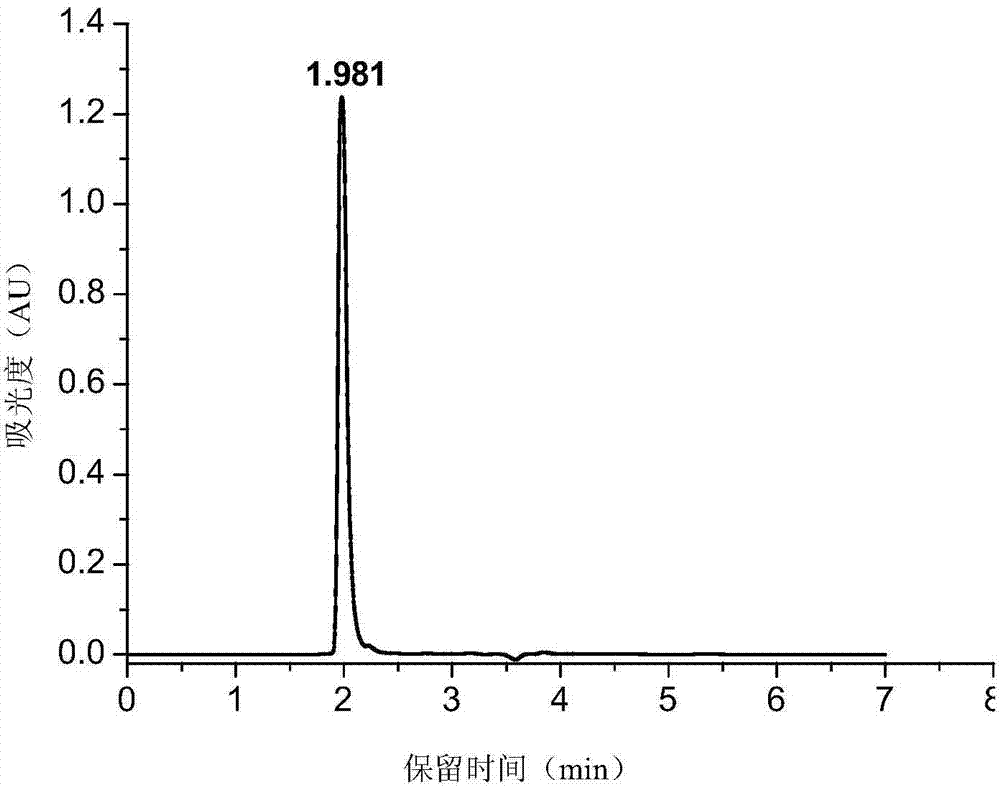

[0045] Take fresh sturgeon spine tissue and place it in a boiling water bath for 1 hour, remove muscle, fat and other attachments on the surface of the spine, soak in petroleum ether, wash with alcohol, dry at 70°C, pulverize with a grinder, and weigh for later use. Weigh 30g of cartilage granules, add 4% NaOH solution according to the ratio of material to liquid 1:5, and stir at 45°C for 30min. After adjusting the pH to 7.0 with hydrochloric acid, add malic acid until the pH is 3.0, add pepsin with 1% cartilage mass, and stir at a constant temperature of 37°C for 4 hours, during which the pH is adjusted to be stable at 3.0. Adjust the pH to 5.0, add papain and cellulase with 4% cartilage mass in a ratio of 1.2:1, stir at 55°C for 4 hours, and adjust the pH to stabilize at 5.0 during this period. Add 0.5% activated carbon in the volume of the solution, stir at 80°C for 30 minutes, cool and filter to obtain the enzymolysis solution. Adjust the pH to 6.0, adjust the NaCl concen...

Embodiment 3

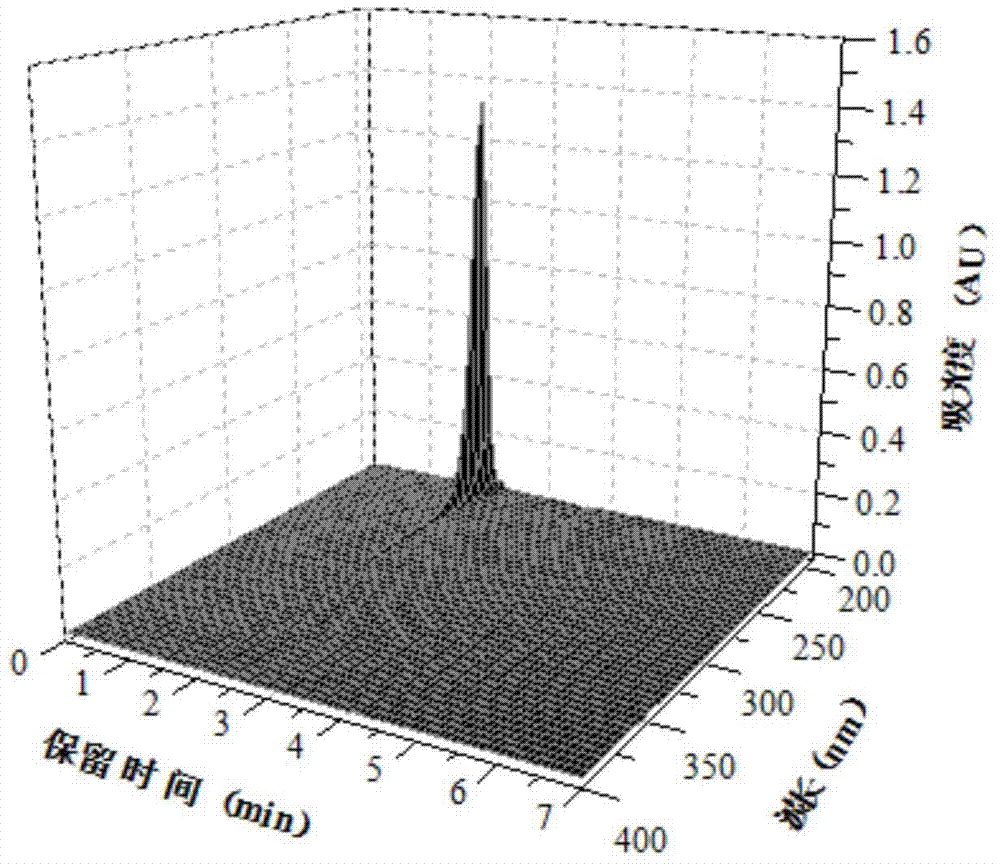

[0047] Take fresh sturgeon spine tissue and place it in a boiling water bath for 1 hour, remove muscle, fat and other attachments on the surface of the spine, soak in petroleum ether, wash with alcohol, dry at 70°C, pulverize with a grinder, and weigh for later use. Weigh 30g of cartilage particles, add 6% NaOH solution according to the ratio of material to liquid 1:5, and stir at 50°C for 45min. After adjusting the pH to 7.0 with hydrochloric acid, add malic acid until the pH is 3.0, add pepsin with 1% cartilage mass, and stir at a constant temperature of 37°C for 4 hours, during which the pH is adjusted to be stable at 3.0. Adjust the pH to 5.5, add papain and cellulase with a mass of 4% cartilage at a ratio of 1.4:1, stir at 60°C for 4 hours, and adjust the pH to stabilize at 5.5. Add 0.5% activated carbon by volume of the solution, stir at 90°C for 30 minutes, cool and filter to obtain the enzymatic hydrolysis solution. Adjust the pH to 6.0, adjust the NaCl concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com