Natural gas well foam draining extraction emulsion demulsifying agent

A technology for foam drainage and emulsification, which is used in chemical dehydration/demulsification, immiscible liquid separation, petroleum industry, etc. Clear interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

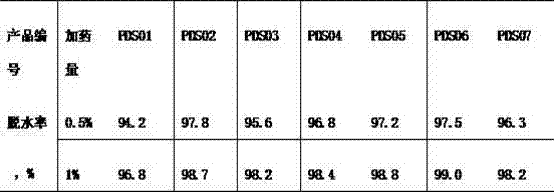

Examples

Embodiment 1

[0045] Pump 120kg of 200# solvent oil, 100kg of ethanol and 148.5kg of diethanolamine into the 2M 3 In the reaction kettle, turn on the stirring device, add 57.6 kg of linear dodecylbenzenesulfonic acid, heat to 50 ° C, stir and react for 0.5 hours, then add 541.5 kg of water, and sequentially add 0.8 kg of citric acid, 75.6 kg of sodium sulfate and 100 kg of block polyether 6020 and 56 kg of block polyether 1121 were stirred and reacted at 50°C for 1 hour, and cooled out of the kettle to obtain PDS01, a light yellow viscous foam drainage demulsifier product.

Embodiment 2

[0047] Pump 120kg of 200# solvent oil, 100kg of methanol and 162.6kg of triethanolamine into the 2M 3 In the reaction kettle, turn on the stirring device, add 68.2 kg of linear tetradecylbenzenesulfonic acid, heat to 50°C, stir and react for 0.5 hours, then add 520.3 kg of water, and sequentially add 0.9 kg of citric acid and 72.0 kg of sodium chloride With 100 kg of block polyether 6030 and 56 kg of block polyether 1121, continue to stir and react at 50 ° C for 1 hour, and cool it out of the kettle to obtain a light yellow viscous foam drainage demulsifier product PDS02.

Embodiment 3

[0049] Pump 120kg of 200# solvent oil, 100kg of methanol and 151.2kg of triethylamine into the 2M 3 In the reaction kettle, turn on the stirring device, add 72.5 kg of linear hexadecylbenzenesulfonic acid, heat to 50 ° C, stir and react for 0.5 hours, then add 530.4 kg of water, and then add 0.9 kg of citric acid, 70.0 kg of potassium sulfate and 100 kg of block polyether 6101 and 55 kg of block polyether 1531 were stirred and reacted at 50°C for 1 hour, and cooled out of the kettle to obtain PDS03, a light brown viscous foam drainage demulsifier product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com