A preparation method for condensate oil-water emulsion demulsifier

A technology for water emulsion and condensate oil, applied in the direction of dehydration/demulsification by chemical methods, etc., can solve the problems of wasting energy, affecting gas well productivity, sewage environmental protection and safety substandard, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

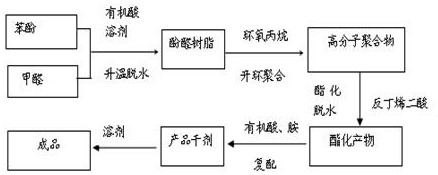

Method used

Image

Examples

preparation example Construction

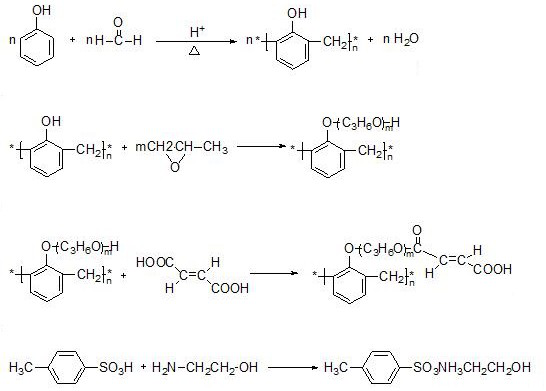

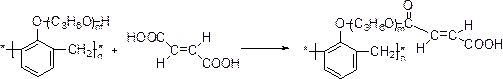

[0029] A preparation method for condensate oil-water emulsion demulsifier, the preparation steps are:

[0030] (1) Add phenol into the reaction kettle, heat up to 90°C, stir for 30 minutes after the product melts, add dodecylbenzenesulfonic acid, add 1500# solvent oil, and stir for 10 minutes. Lower the temperature to 80°C, and add formaldehyde dropwise at 75°C to 80°C. After the dropwise addition, keep the reaction at this temperature for 1 hour. Then heat up and reflux to divide the water, and the temperature is controlled between 125-155°C until no more water is precipitated;

[0031] (2) Cool down the temperature of the product obtained in step ⑴ to 58-60°C, add 10%-20% potassium methoxide solution (mass percentage of potassium methoxide in methanol) from the upper part of the reactor dropwise, stir evenly, and evacuate to the reactor The internal pressure reaches -0.08MPa, the vacuum time is ≥ 30 minutes, until the moisture is controlled below 0.05% (mass percentage), st...

Embodiment 1

[0050] (1) Add 200kg of phenol into the reaction kettle, heat up to 90°C, stir for 30 minutes after the product melts, add 2kg of dodecylbenzenesulfonic acid, add 50kg of 1500# solvent oil, and stir for 10 minutes. Lower the temperature to 80°C, and add 66kg of formaldehyde dropwise at 75°C to 80°C. After the dropwise addition, keep the reaction at this temperature for 1 hour. Then raise the temperature and reflux to divide the water, and the temperature is controlled between 125-155°C until no more water is precipitated; the phenolic resin is obtained.

[0051](2) Cool down the phenolic resin to 90°C, vacuumize until the pressure in the reactor reaches -0.08MPa, the vacuum time should not be less than 30 minutes, and then check the moisture until the moisture is controlled below 0.05%, then stop the vacuum.

[0052] (3) Cool down to 58-60°C, add 160 kg of 10% potassium methoxide solution from the drip tank on the upper part of the reaction kettle, of which 10% potassium metho...

Embodiment 2

[0057] (1) Add 200kg of phenol into the reaction kettle, raise the temperature to 90°C, stir for 30 minutes after the product melts, add 2kg of dodecylbenzenesulfonic acid, add 66kg of 1500# solvent oil, and stir for 10 minutes. Lower the temperature to 80°C, and add 58kg of formaldehyde dropwise at 75°C to 80°C. After the dropwise addition, keep the reaction at this temperature for 1 hour. Then raise the temperature and reflux to divide the water, and the temperature is controlled between 125-155°C until no more water is precipitated; the phenolic resin is obtained.

[0058] (2) Cool down the phenolic resin to 90°C, vacuumize until the pressure in the reactor reaches -0.08MPa, the vacuum time should not be less than 30 minutes, and then check the moisture until the moisture is controlled below 0.05%, then stop the vacuum.

[0059] (3) Cool down to 58-60°C, add 200kg of 10% potassium methoxide solution from the drip tank on the upper part of the reaction kettle, wherein the 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com