Method for preparing demulsifying agent for condensed oil-water emulsion

A technology for water emulsion and condensate oil, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of wasting energy, affecting the productivity of gas wells, sewage environmental protection and safety substandard, etc., to reduce pollution and reduce the oil content of sewage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

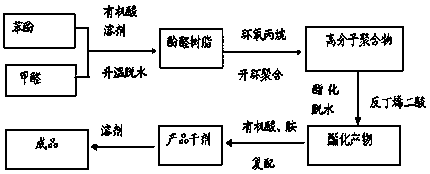

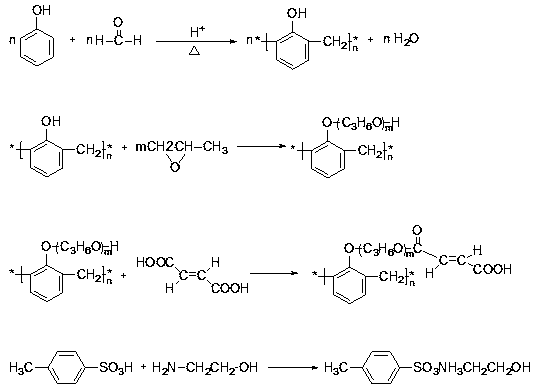

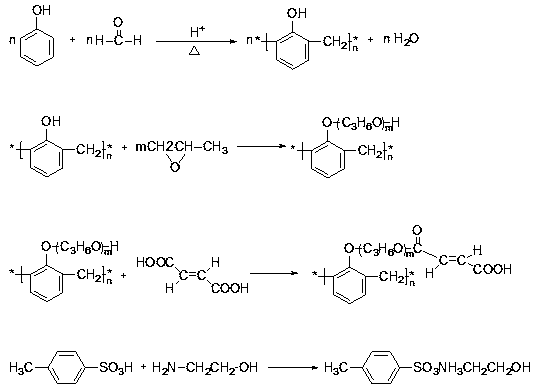

[0029] A preparation method for condensate oil-water emulsion demulsifier, the preparation steps are:

[0030] (1) Add phenol into the reaction kettle, heat up to 90°C, stir for 30 minutes after the product melts, add dodecylbenzenesulfonic acid, add 1500# solvent oil, and stir for 10 minutes. Lower the temperature to 80°C, and add formaldehyde dropwise at 75°C to 80°C. After the dropwise addition, keep the reaction at this temperature for 1 hour. Then heat up and reflux to divide the water, and the temperature is controlled between 125-155°C until no more water is precipitated;

[0031] (2) Cool down the temperature of the product obtained in step ⑴ to 58-60°C, add 10%-20% potassium methoxide solution (mass percentage of potassium methoxide in methanol) from the upper part of the reactor dropwise, stir evenly, and evacuate to the reactor The internal pressure reaches -0.08MPa, the vacuum time is ≥ 30 minutes, until the moisture is controlled below 0.05% (mass percentage), st...

Embodiment 1

[0050] (1) Add 200kg of phenol into the reaction kettle, raise the temperature to 90°C, stir for 30 minutes after the product melts, add 2kg of dodecylbenzenesulfonic acid, add 50kg of 1500# solvent oil, and stir for 10 minutes. Lower the temperature to 80°C, and add 66kg of formaldehyde dropwise at 75°C to 80°C. After the dropwise addition, keep the reaction at this temperature for 1 hour. Then raise the temperature and reflux to divide the water, and the temperature is controlled between 125-155°C until no more water is precipitated; the phenolic resin is obtained.

[0051](2) Cool down the phenolic resin to 90°C, vacuumize until the pressure in the reactor reaches -0.08MPa, the vacuum time should not be less than 30 minutes, and then check the moisture until the moisture is controlled below 0.05%, then stop the vacuum.

[0052] (3) Cool down to 58-60°C, add 160 kg of 10% potassium methoxide solution from the drip tank on the upper part of the reaction kettle, of which 10% p...

Embodiment 2

[0057] (1) Add 200kg of phenol into the reaction kettle, raise the temperature to 90°C, stir for 30 minutes after the product melts, add 2kg of dodecylbenzenesulfonic acid, add 66kg of 1500# solvent oil, and stir for 10 minutes. Lower the temperature to 80°C, and add 58kg of formaldehyde dropwise at 75°C to 80°C. After the dropwise addition, keep the reaction at this temperature for 1 hour. Then raise the temperature and reflux to divide the water, and the temperature is controlled between 125-155°C until no more water is precipitated; the phenolic resin is obtained.

[0058] (2) Cool down the phenolic resin to 90°C, vacuumize until the pressure in the reactor reaches -0.08MPa, the vacuum time should not be less than 30 minutes, and then check the moisture until the moisture is controlled below 0.05%, then stop the vacuum.

[0059] (3) Cool down to 58-60°C, add 200kg of 10% potassium methoxide solution from the drip tank on the upper part of the reaction kettle, wherein the 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com