Rust layer direct coating paint composition containing dopamine or its derivatives and preparation method thereof

A technology of dopamine and derivatives, applied in the field of anti-corrosion coatings, can solve the problems of coating performance degradation, etc., and achieve the effect of improving adhesion and corrosion resistance, high adhesion, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composition of this coating is prepared according to the following component ratio (mass percentage):

[0025]

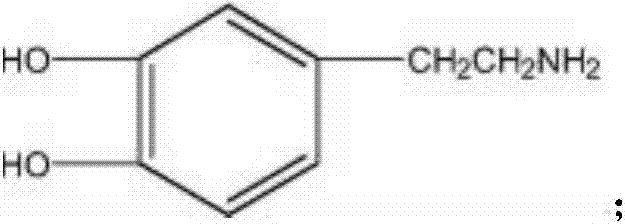

[0026] Described dopamine refers to the substance that is following structure in molecular structure:

[0027]

[0028] The antirust pigment is a mixture of zinc phosphate and calcium carbonate treated with an amino coupling agent, the particle size of the calcium carbonate is 10 μm, and its mass ratio is zinc phosphate: calcium carbonate = 3:1.

[0029] The filler includes a mixture of talc powder and wollastonite, and the mixing mass ratio is talc powder: wollastonite=10:3.

[0030] The structural formula of the compound containing double bond is:

[0031] The composition of this coating is prepared as follows: mix and stir the above-mentioned components evenly, and then grind them on a grinder until the particle size reaches 0.5 μm, then fill it, and adjust it with an appropriate amount of water during construction. to the proper viscosity. ...

Embodiment 2

[0034] The composition of this coating is prepared according to the following component ratio (mass percentage):

[0035]

[0036] The dopamine derivative I refers to a substance having the following structure in the molecular structure:

[0037]

[0038] The antirust pigment is a mixture of zinc phosphate and calcium carbonate treated with an amino coupling agent, the particle size of the calcium carbonate is 30 μm, and its mixing mass ratio is zinc phosphate: calcium carbonate=3:1.

[0039] The filler is a mixture of talcum powder and wollastonite, and its mixing mass ratio is talcum powder: wollastonite=10:3.

[0040] The compound containing a double bond refers to a substance whose molecular structure is as follows:

[0041]

[0042] The composition of this coating is prepared as follows: mix and stir the above-mentioned components evenly, then grind them on a grinder until the particle size reaches 1 μm, and then fill it. During construction, you can use an appr...

Embodiment 3

[0045] The composition of this coating is prepared according to the following component ratio (mass percentage):

[0046]

[0047] Described dopamine refers to the material that is following structure in molecular structure:

[0048]

[0049] The antirust pigment is a mixture of zinc phosphate and calcium carbonate treated with an amino coupling agent, the particle size of the calcium carbonate is 50 μm, and the mixing mass ratio is zinc phosphate: calcium carbonate=3:1.

[0050] The filler is a mixture of talcum powder and wollastonite, and its mixing mass ratio is talcum powder: wollastonite=10:3.

[0051] The compound containing a double bond refers to a substance whose molecular structure is as follows:

[0052]

[0053] The composition of this coating is prepared as follows: mix and stir the above-mentioned components evenly, and then grind them on a grinder until the particle size reaches 0.5 μm, then fill it, and adjust it with an appropriate amount of water d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com