A Palletizing Arrangement Mechanism with Reserved Gap

A technology of reserved clearance and push mechanism, applied in the stacking, conveyor, loading/unloading and other directions of objects, it can solve the problem that the size of the brick stack cannot be adjusted, the brick stacker does not have the function of arranging, and the mixed brick cannot be stacked. stacking and other problems to achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

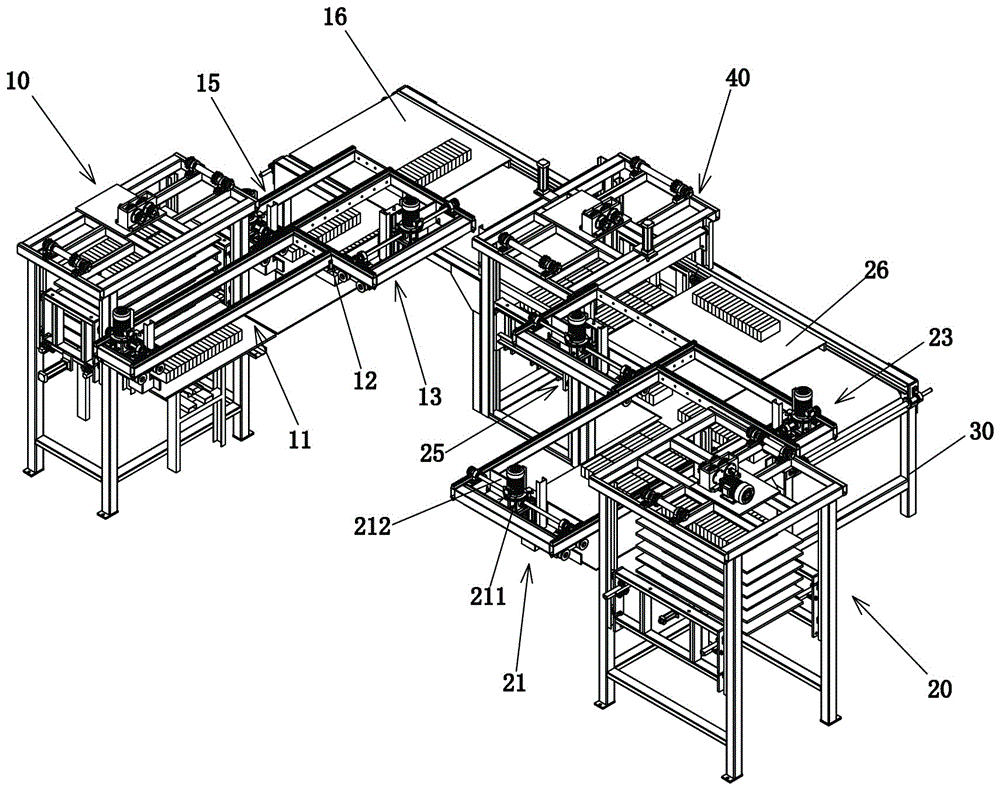

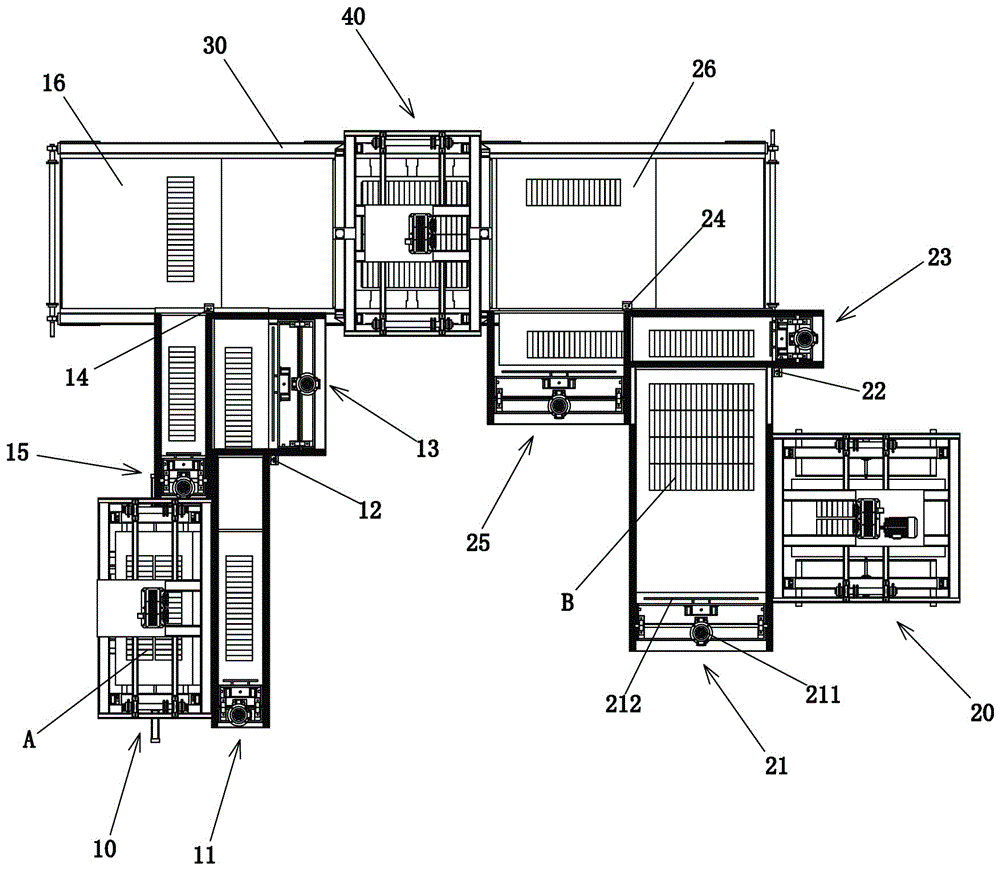

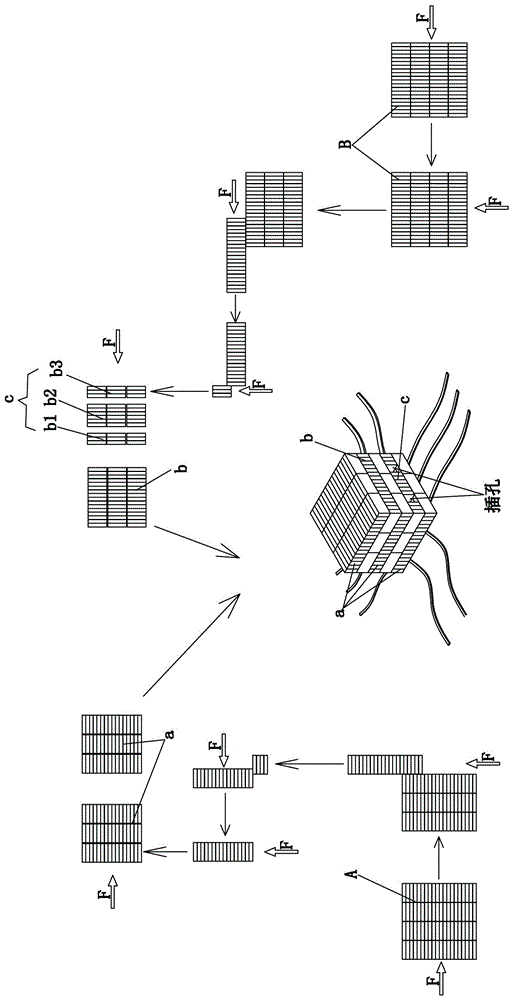

[0024] refer to figure 1 and figure 2 As shown, a kind of stacking arrangement mechanism with reserved clearance includes a frame 30 and a control system (not shown in the figure) that are provided with tracks and conveyor belts. The frame 30 is provided with a slidable carrier plate 16 and a plate 26.

[0025] The frame 30 is provided with a pushing mechanism that provides bricks for the carrier plate 16, and the pushing mechanism includes successively according to the conveying direction of the bricks: the first pushing device 11 that pushes the bricks forward, the pushing direction and the first pushing device 11. The second pushing device 13 whose pushing direction is vertical, the third pushing device 15 whose pushing direction is parallel to the pushing direction of the first pushing device 11; Bricks pass through a detection device 12 that is counted and connected with the control system. Between the second pushing device 13 and the third pushing device 15, a detect...

Embodiment 2

[0049] refer to Figure 4 As shown, a kind of stacking arrangement mechanism with reserved gaps includes a frame 30 and a control system (not shown in the figure) that are provided with tracks and conveyor belts. The frame 30 is provided with a slidable carrier plate 26 and two A push mechanism that provides bricks for the carrier 26 and is located on opposite sides of the carrier 26 .

[0050] refer to Figure 4 As shown, one of the pushing mechanisms comprises successively by the conveying direction of the bricks: the first pushing device 11 that pushes the bricks forward, the second pushing device 13 whose pushing direction is perpendicular to the pushing direction of the first pushing device 11, the pushing Direction is the 3rd pushing device 15 parallel to the pushing direction of the first pushing device 11; A detection device 12 for detecting the passing number of bricks and being connected with the control system is provided between the first pushing device 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com