Washing device of casting water-soluble salt core

A technology of flushing device and water-soluble salt, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of long operation time, piston corrosion, and inability to form internal cooling oil passages, so as to reduce the residual rate and meet the requirements of use. , The effect of improving the efficiency of washing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be described below in conjunction with specific embodiments.

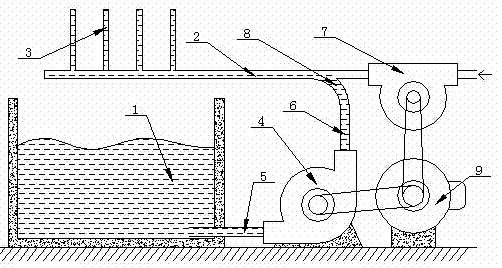

[0015] Such as figure 1 Shown is a structural schematic diagram of a flushing device for casting water-soluble salt cores according to the present invention. A flushing device for casting water-soluble salt cores according to the present invention includes: a circulating water pool 1 for providing flushing water sources and recovering flushing water, a flushing water spray pipe 2 is arranged above the circulating pool 1, and the flushing The downstream end of the water spray pipe 2 is provided with several flushing nozzles 3; a pressurized water pump 4 for pressurized flushing water source, the water inlet end of the pressurized water pump 4 is connected to the circulating pool 1 through the water inlet pipe 5, so The water outlet end of the pressurized water pump 4 is connected to the flushing water spray pipe 2 through the water outlet pipe 6; the air compressor p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com