Automatic tube bending machine

A pipe bending machine, automatic technology, applied in the direction of metal processing equipment, feeding device, positioning device, etc., can solve the problems of cumbersome operation and low production efficiency, and achieve the effect of improving production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

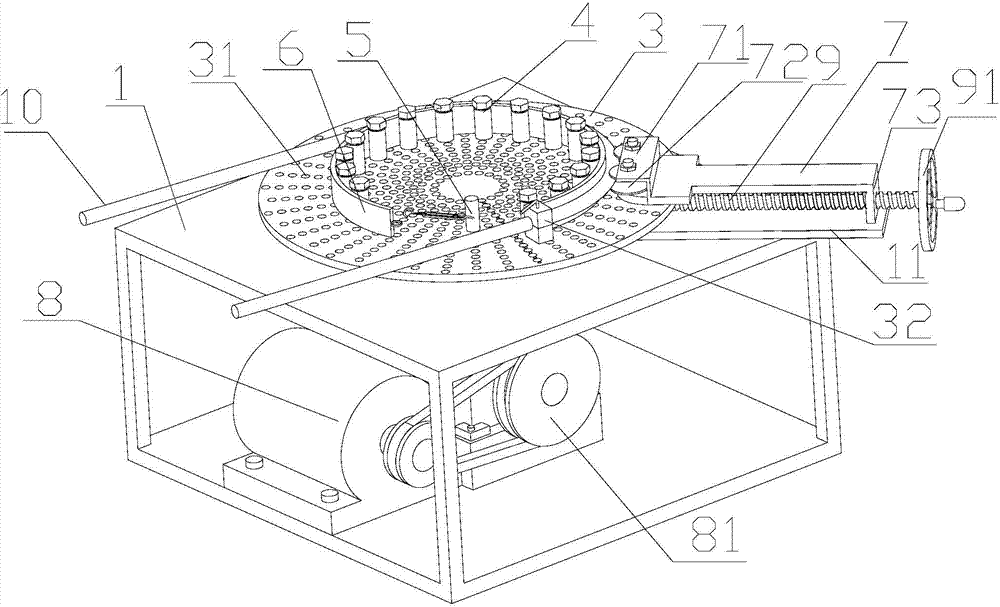

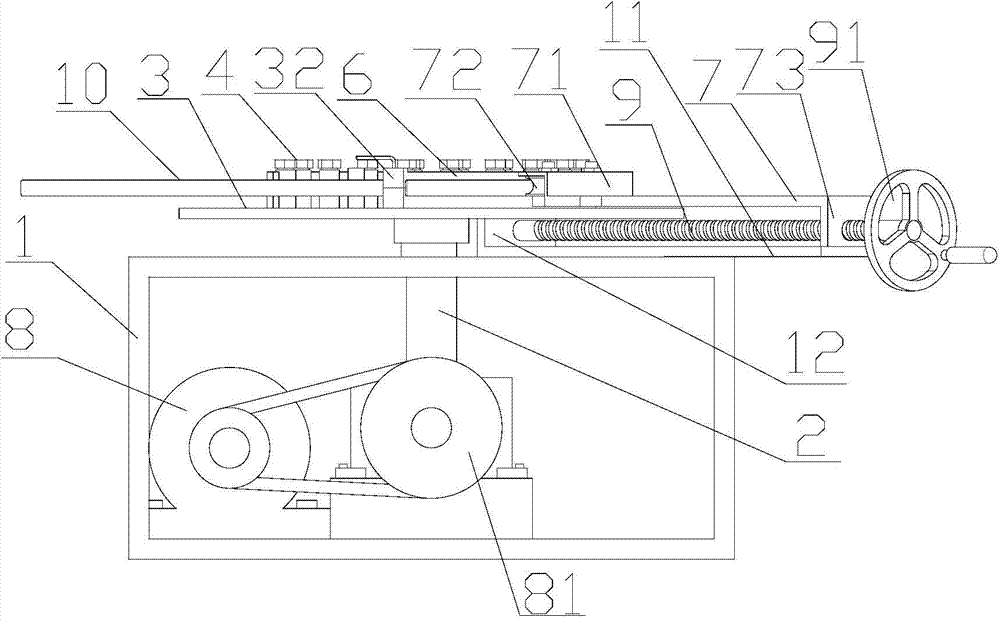

[0019] Such as figure 1 and 2 Shown, a kind of automatic pipe bending machine, frame 1, driving device, drive shaft 2, rotating disc 3, several positioning rods 4, positioning column 5, sleeve plate 6 and pressure bar 7; Described driving device provides power and The driving shaft 2 is connected by transmission, and one end of the driving shaft 2 is fixedly installed in the center of the rotating disk 3, and the rotating disk 3 is provided with a plurality of positioning holes 31 on the circumference of different radii with its center as the center, and the positioning rod 4 and the positioning column 5 It can be detachably installed in the positioning hole 31 on the circumference of the same radius, and the sleeve plate 6 is an annular steel plate with a gap, and the sleeve plate 6 is set on the outside of the positioning rod 4, and its two ends are fixed on the positioning column 5; A fixing device 32 for fixing the pipe material 10 can also be detachably installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com