Embedded sensing chip encapsulation structure with vertical through hole and manufacturing method thereof

A sensor chip and vertical through-hole technology, applied in the field of chip interconnection, can solve the problems of low yield, high cost of metal wiring, long-term reliability risks of products, etc., and achieve the effect of high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention will be further described below according to the accompanying drawings.

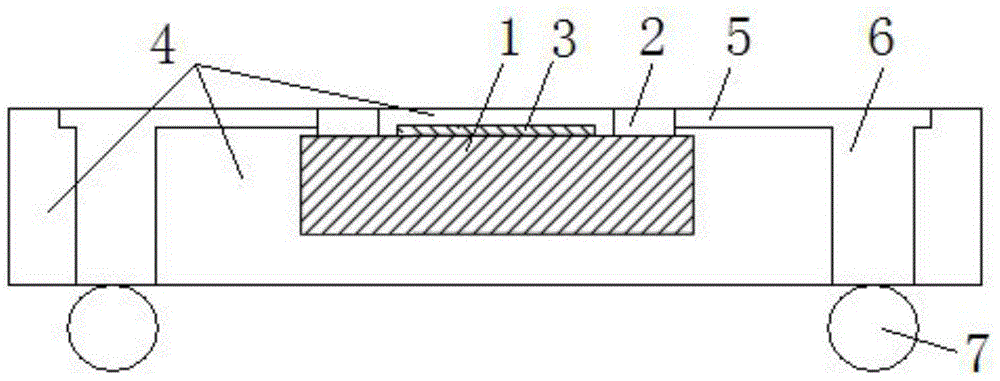

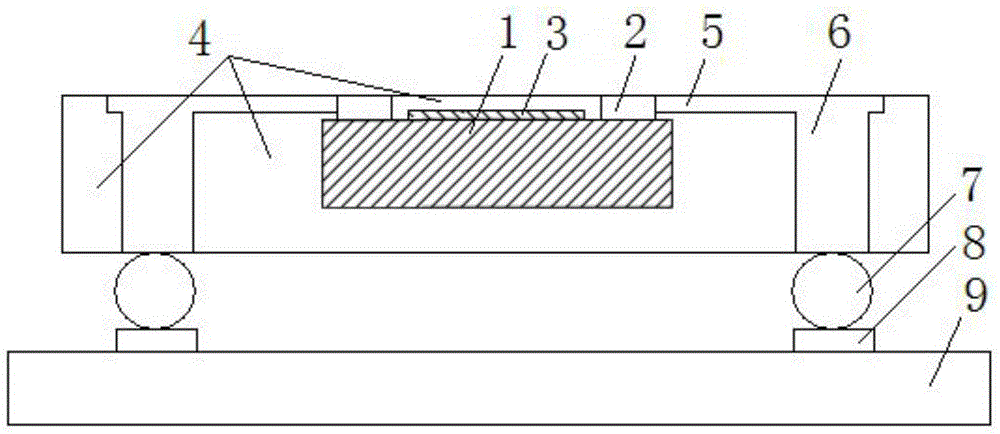

[0044] An embedded sensor chip packaging structure with vertical through holes, the structure includes a sensor chip 1, a sensor chip pad 2, a sensor structure part 3, a medium 4, a conductive line 5, and a through hole filled with a conductive material. holes 6, solder balls 7; the sensor chip 1 can be a fingerprint identification chip or other sensor chips, the sensor chip pad 2 is located on the top surface of the sensor chip 1, and the sensor structure part 3 is soldered to the sensor chip The disk 2 is located on the same surface, the side of the sensor chip 1 is covered with a medium 4, and there is a through hole 6 filled with a conductive material inside the medium 4, and the through hole 6 filled with a conductive material is connected with the conductive circuit 5 on the surface of the medium 4 and the conductive line 5 on the medium 4. The solder balls 7 on the back of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com