Combined assembly type construction method for integrated units of full-story-height metal sandwich board internal partition wall

A combined assembly and construction method technology, applied to walls, passive houses, climate change adaptation, etc., can solve the problems that restrict the promotion and application of metal sandwich panels, and achieve the advantages of ensuring firmness, novel and reasonable design, and enhancing sound insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

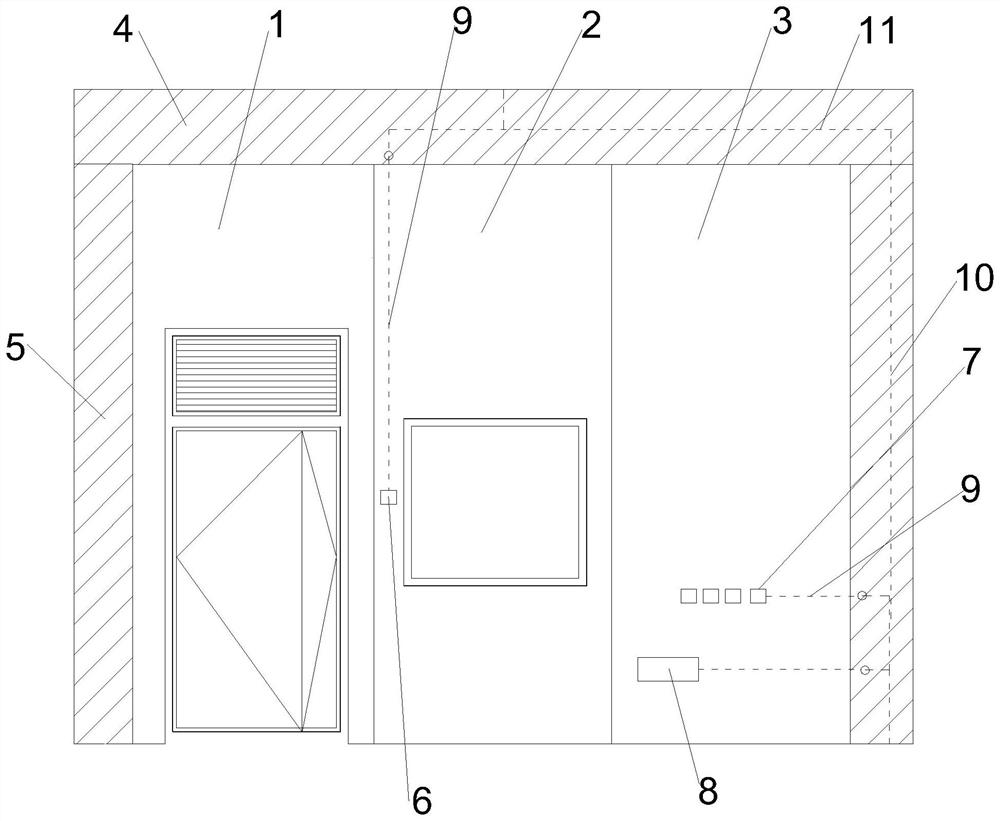

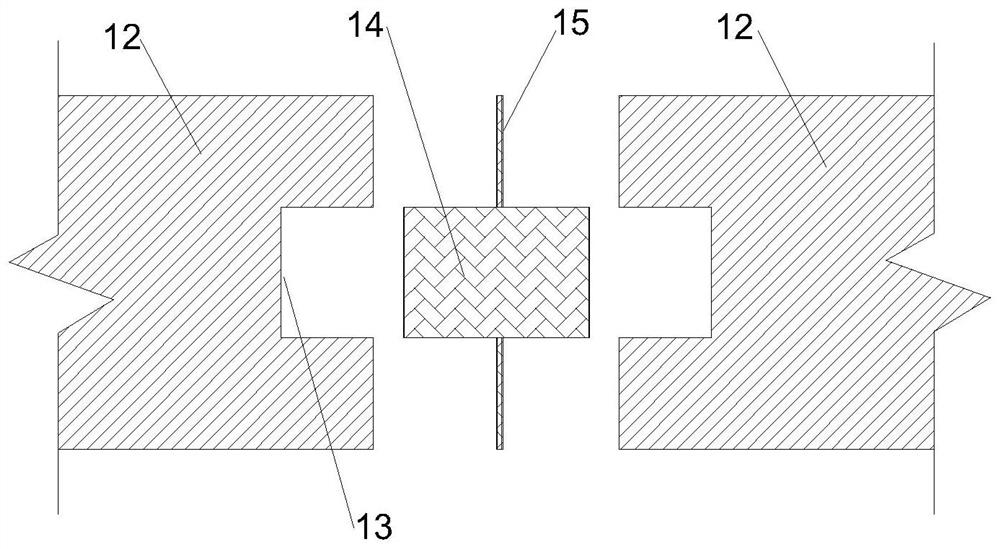

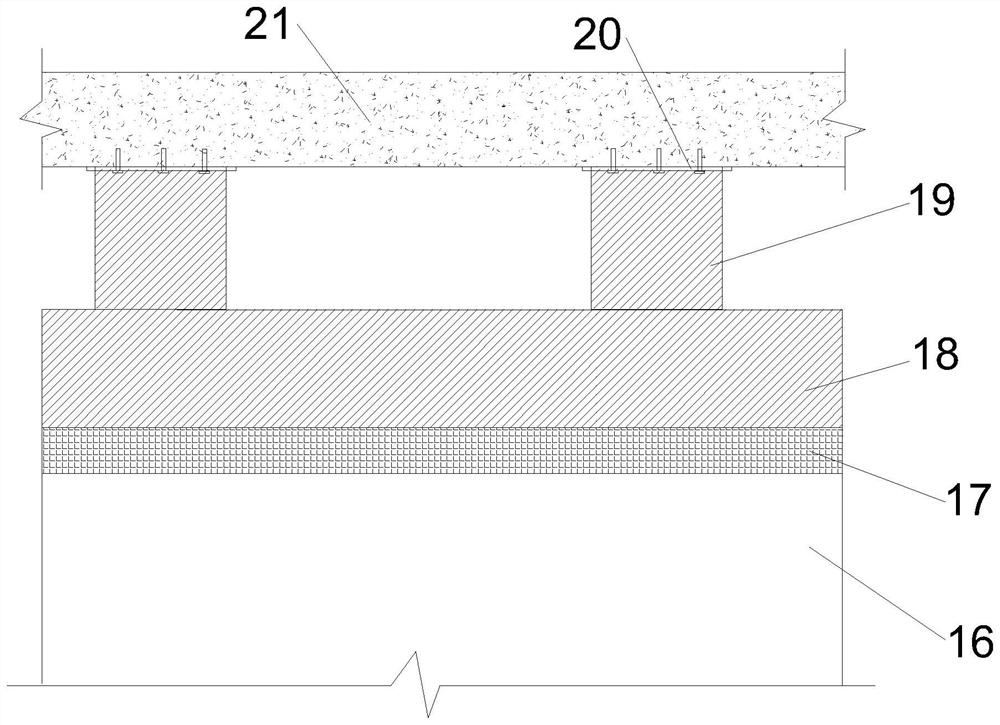

[0064] like Figure 1 to Figure 10 As shown, the present invention's full-story metal sandwich panel inner partition wall integrated unit combined assembly construction method includes the following steps:

[0065] Step 1. Determine the width of the column panel, the length of the transverse connecting rod, the height of the connecting block and the height of the beam panel: conduct a detailed design on the extension direction of the inner partition wall in the building construction layer, decompose the inner partition wall into units, and divide it into Standard part and non-standard part, the inner partition wall of the standard part is a metal inner partition wall 16, and the inner partition wall of the non-standard part is a non-standard steel column 5, and the width of the column panel 32 is determined according to the width of the non-standard steel column 5, according to The height of the building construction layer and the height of the metal inner partition wall 16 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com