Vertical sintering waste heat driven cogeneration system and method thereof

A combined cooling, heating and power, vertical technology, applied in the field of vertical sintering waste heat driving combined cooling, heating and power systems, can solve problems such as low thermal efficiency, and achieve the effect of improving utilization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

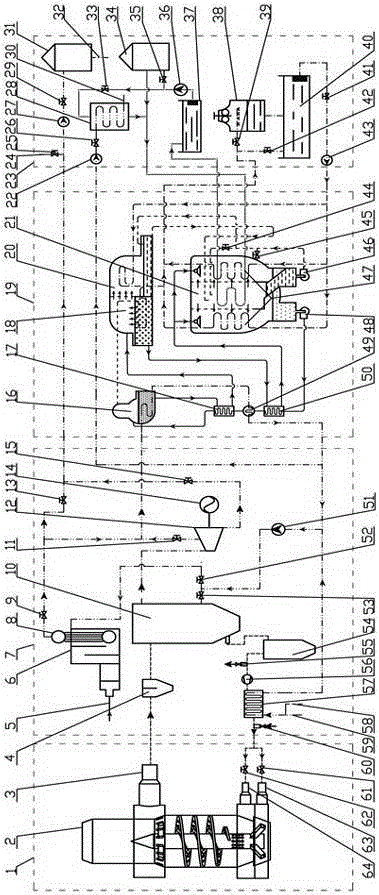

[0021] Such as figure 1 As shown, the vertical sintering waste heat driven combined cooling, heating and power system includes a sinter vertical cooling device 1, a waste heat boiler power generation and steam generation system 7, a double-effect lithium bromide refrigeration unit 19 and a refrigerant cooling water user end system 23; Type cooling device 1 includes sinter vertical cooling device body 2, annular air inlet pipe 64, central air inlet pipe 63, annular air inlet regulating valve 62, central air inlet regulating valve 61 and air outlet pipe 3; waste heat boiler power generation and steam The generating system 7 includes a waste heat boiler 10, a primary dust collector 4, a secondary dust collector 54, a circulating fan 56, an extraction back pressure steam turbine 12, a generator 14, a secondary economizer 57, a main water supply pipe 59 for the secondary economizer, Sub economizer auxiliary water supply pipe 58, relief valve 55, cold air intake valve 60, gas supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com