Low-temperature and low-pressure freeze-drying method of pseudo-ginseng chewable tablets

A low-temperature, low-pressure, drying method technology, applied in the direction of drying solid materials, drying solid materials without heating, and promoting the preliminary treatment of solid materials drying, etc., can solve the problem of active ingredients, active ingredient damage, transportation, storage difficulties, difficult crushing, etc. problem, to achieve the effect of retaining the active ingredient content, saving freeze-drying time, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

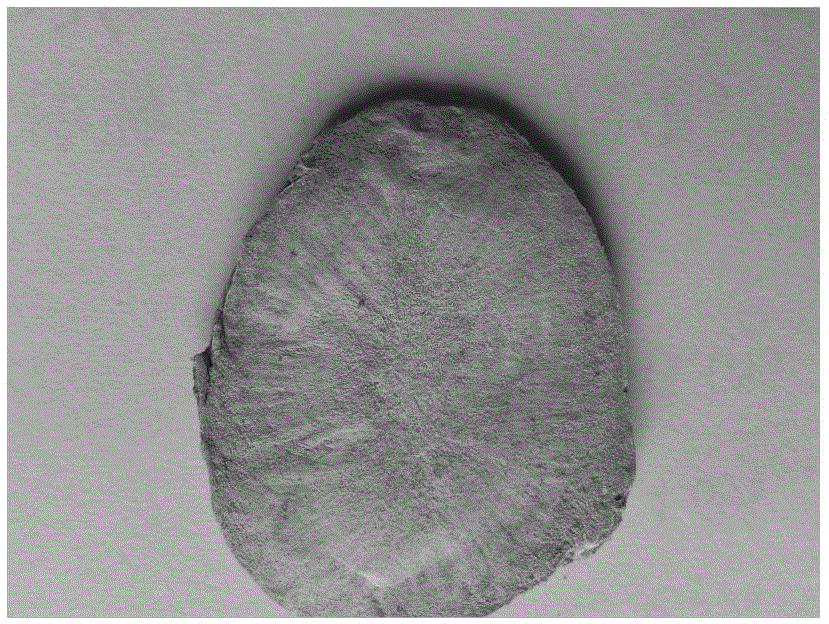

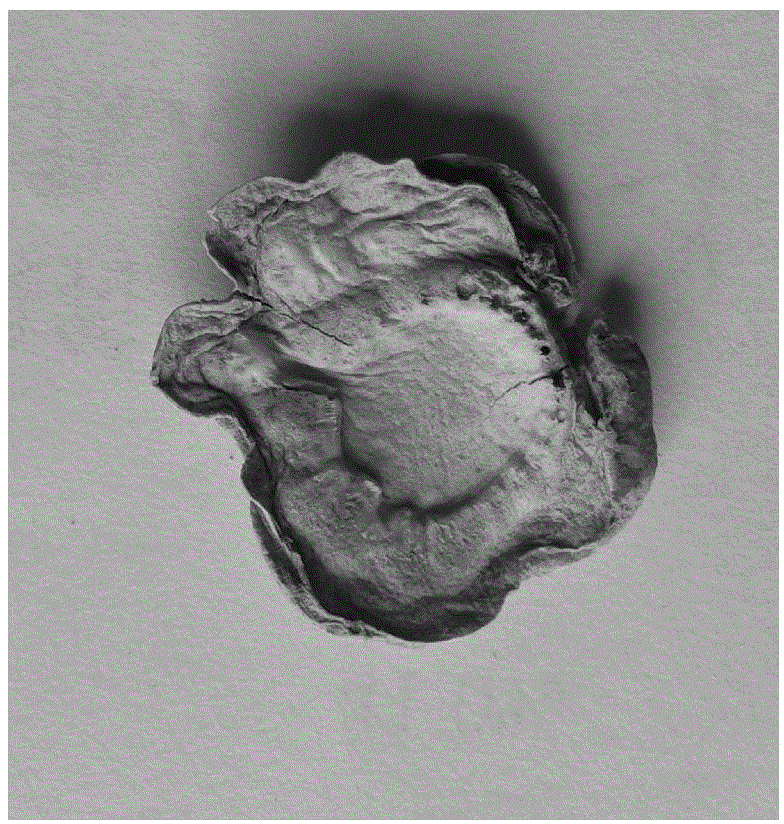

Image

Examples

Embodiment 1

[0023] A low-temperature and low-pressure freeze-drying method for notoginseng chewable tablets, comprising the following steps:

[0024] (1) Pretreatment: Remove the fibrous root, velvet root and notch of fresh Panax notoginseng to obtain the main root, wash with sterile water, and drain the water; The tablet is sprayed with an aqueous solution of tea polyphenols with a mass concentration of 10% and an aqueous solution of sucrose with a mass concentration of 20%, and the mass ratio of the Panax notoginseng tablets to the aqueous solution of tea polyphenols and aqueous sucrose is 2:1:1;

[0025] (2) Pre-freezing: place the notoginseng tablets obtained in step 1) in a vacuum desiccator, cool down to -35°C, and freeze the notoginseng tablets;

[0026] (3) Vacuum freeze-drying: evacuate the vacuum dryer to make the pressure 15Pa, keep it for 1.5 hours, heat it, and raise the temperature from -35°C to 0°C in 25 hours, then heat it again, and make the temperature from -35°C to 0°C ...

Embodiment 2

[0029] A low-temperature and low-pressure freeze-drying method for notoginseng chewable tablets, comprising the following steps:

[0030] (1) Pretreatment: Remove the fibrous root, velvet root and notch of the fresh Panax notoginseng root to obtain the main root, wash it with sterile water, and drain the water; The tablet is sprayed with an aqueous solution of tea polyphenols with a mass concentration of 5% and an aqueous solution of fructose with a mass concentration of 60%, and the mass ratio of the Panax notoginseng tablets to the aqueous solution of tea polyphenols and aqueous fructose is 1:1:1;

[0031] (2) Pre-freezing: place the notoginseng tablets obtained in step 1) in a vacuum desiccator, cool down to -30°C, and freeze the notoginseng tablets;

[0032] (3) Vacuum freeze-drying: evacuate the vacuum dryer to make the pressure 10Pa, keep it for 1 hour, heat it, and raise the temperature from -30°C to 0°C in 20 hours, then heat it again, and make the temperature from -30...

Embodiment 3

[0033] Embodiment 3 A low-temperature and low-pressure freeze-drying method of notoginseng chewable tablets, comprising the following steps:

[0034] (1) Pretreatment: Remove the fibrous root, velvet root and notch of fresh Panax notoginseng to obtain the main root, wash with sterile water, drain the water; slice to obtain Panax notoginseng slices with a thickness of 5mm, The tablet is sprayed with an aqueous solution of tea polyphenols with a mass concentration of 20% and an aqueous solution of sucralose with a mass concentration of 1%, and the mass ratio of the Panax notoginseng tablets to the aqueous solution of tea polyphenols and aqueous sucralose is 4:1:1;

[0035] (2) Pre-freezing: place the notoginseng tablets obtained in step 1) in a vacuum desiccator, cool down to -40°C, and freeze the notoginseng tablets;

[0036] (3) Vacuum freeze-drying: evacuate the vacuum dryer to make the pressure 20Pa, keep it for 2 hours, heat it, and raise the temperature from -40°C to 0°C i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com