Machining method of bulb lamp body

A processing method and technology for bulb lamps, which can be applied to lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc. The effect of large heat dissipation surface area, improved safety factor and high diameter accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

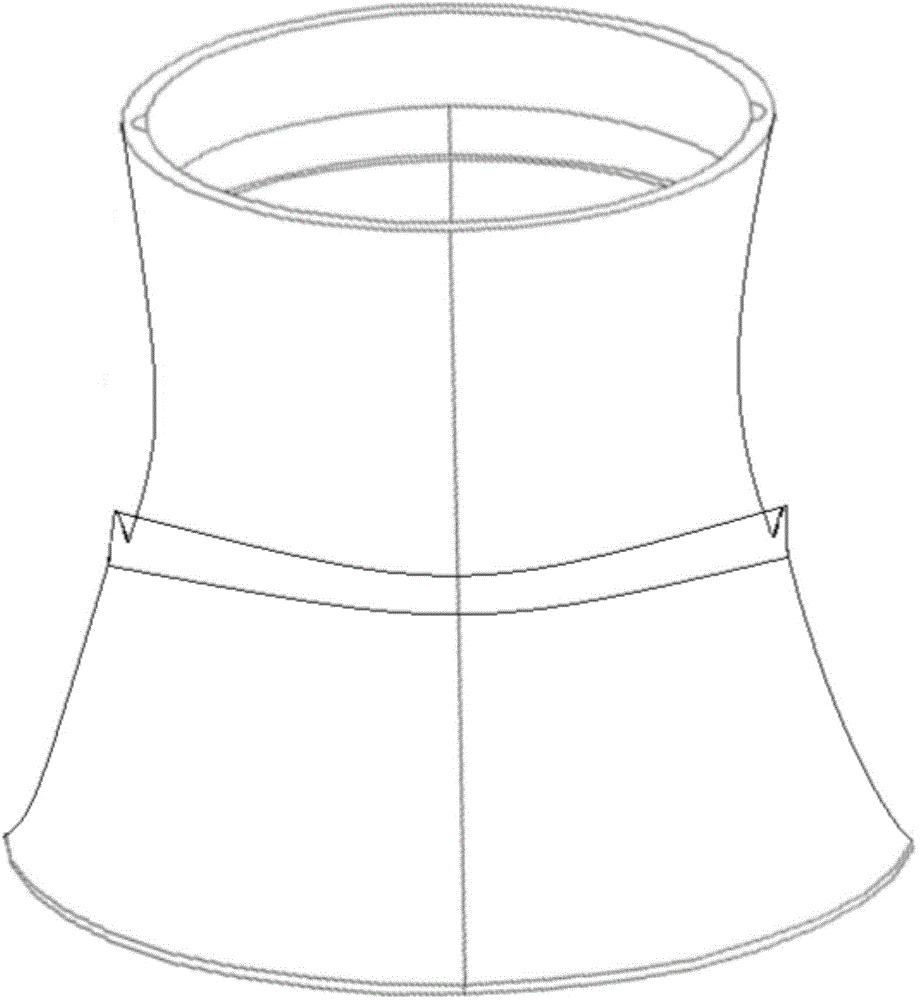

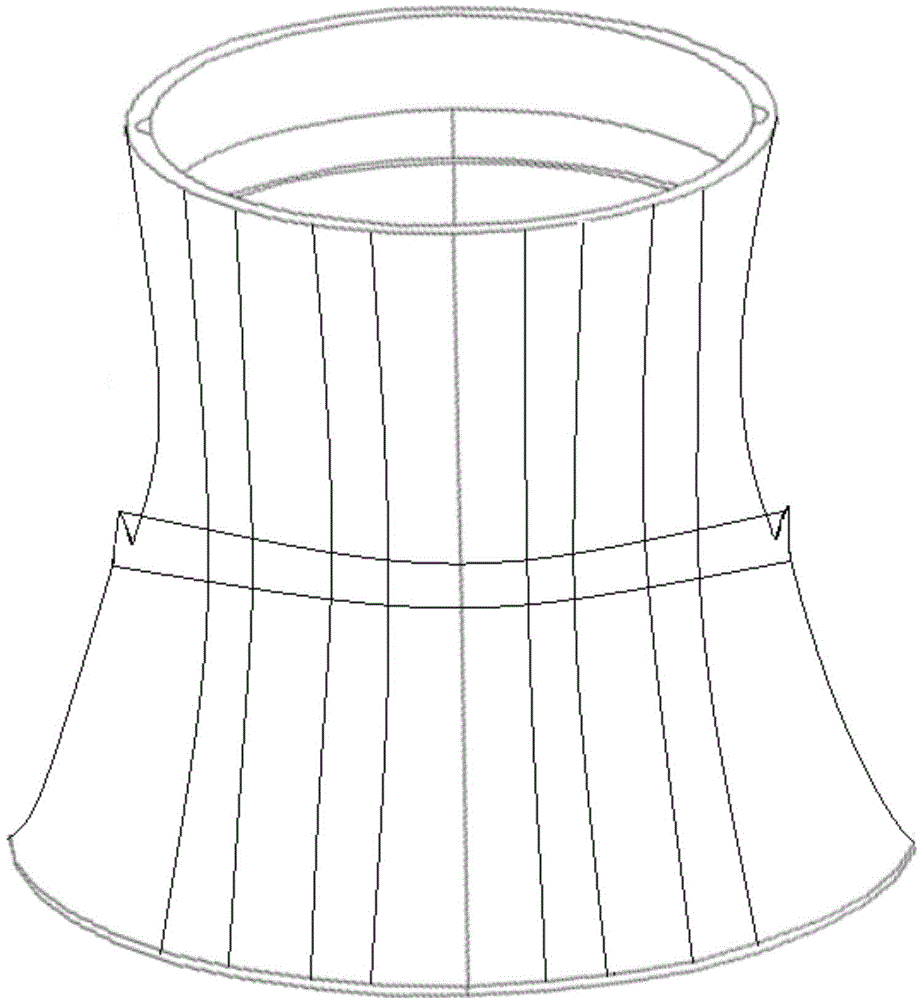

Image

Examples

Embodiment 1

[0029] This embodiment discloses a method for processing the lamp body of an LED light bulb, which includes the following steps:

[0030] (1) Spinning process: take an aluminum alloy circular slab with uniform material, use strong spinning for two-thirds of the part from the inside to the outside along the radial direction of the plate, and use ordinary spinning technology for the last third. Powerful spinning adopts forward spinning, and the workpiece groove of the spinning mold is provided with evenly spaced embossed lines, and the spinning force is a process of gradually increasing, to two-thirds of the part from the inside to the outside along the radial direction of the sheet. reaches the maximum, and the rotation speed of the workpiece during the spinning process is 400m / min;

[0031] (2) Stamping process: Stamp the spun blank. The stamping process includes the punching and drawing process. The punching adopts the positive punching method. The punch in the stamping proce...

Embodiment 2

[0034] This embodiment discloses a method for processing the lamp body of an LED light bulb, which includes the following steps:

[0035] (1) Stamping process: Take a round aluminum alloy slab with uniform material for stamping. The stamping process includes punching and drawing process. The punching adopts the positive punching method. The punch in the stamping process includes three small circular convex die with a non-circular punch;

[0036] (2) Spinning process: Take the blank that has been punched, and use strong spinning for two-thirds of the part from the inside to the outside along the radial direction of the plate, and use ordinary spinning technology for the last third of the part. Forward spinning, the workpiece groove of the spinning mold is provided with evenly spaced convex lines, the spinning pressure is a process of gradual increase, and reaches the maximum at two-thirds of the radial direction of the sheet from the inside to the outside. The rotational speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com