A method for recovering copper and cadmium and preparing cadmium bronze precursor in a compact bioelectrochemical reactor

A technology of bioelectrochemistry and reactor, which is applied in the field of bioelectrochemistry, can solve the problems of high cost, difficult metal recovery, and difficult reaction control, etc., and achieve the effect of convenient operation, efficient recovery, and compact reactor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

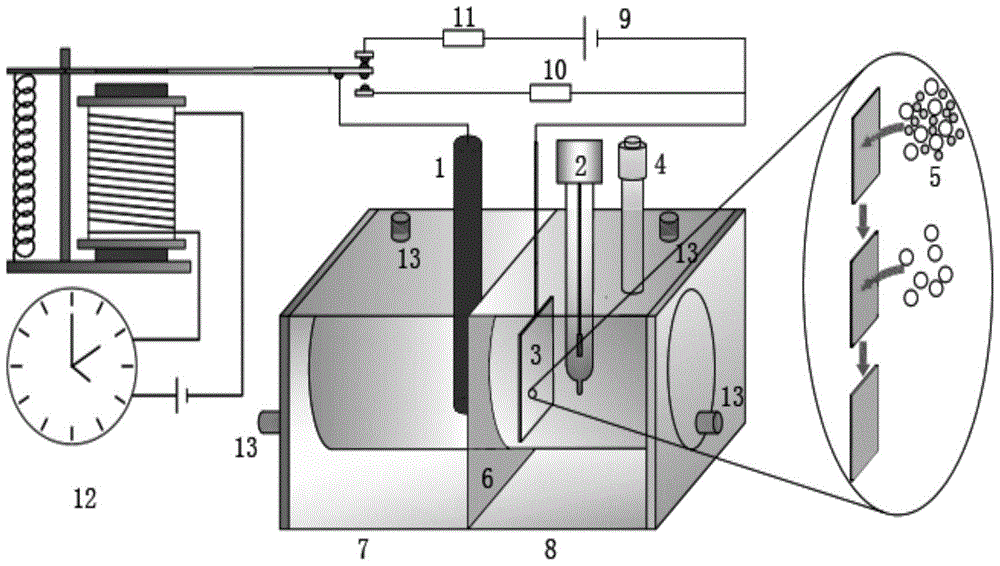

[0030] Step 1: Build the reactor, such as figure 1 Shown: the anode chamber 7 and the cathode chamber 8 of the reactor are made of plexiglass, the volume of the solution in the anode chamber is 15mL, and the solution volume in the cathode chamber is 25mL, separated by an ion exchange membrane (CMI-7000) 6, connected in series with a 200Ω outer tube in the MFCs mode Resistor 10, in MECs mode, connect 10Ω resistor 11 in series and apply 0.5V voltage.

[0031] Step 2: Place the reactor anode electrode (carbon rod and carbon felt) and cathode electrode (carbon cloth) in the reactor anode chamber 7 and cathode chamber 8 respectively. The apparent size of the carbon rod (Beijing Sanye Carbon Material Co., Ltd.) is , carbon felt (Beijing Sanye Carbon Materials Co., Ltd.) with an apparent size of 3.0cm×2.0cm×1.0cm). The reference electrode 2 is connected to the cathode chamber of the reactor, and the voltage across the resistor 11 is collected through the computer and the data acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com