Adhesive powder for sticking waterproof rolls

A waterproof roll material and rubber powder technology, applied in the direction of adhesives, adhesive types, cellulose adhesives, etc., can solve problems such as inconvenient construction, high work intensity, and not densely pasted, and achieve water retention and water resistance Good, reduce overall cost, high paste strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

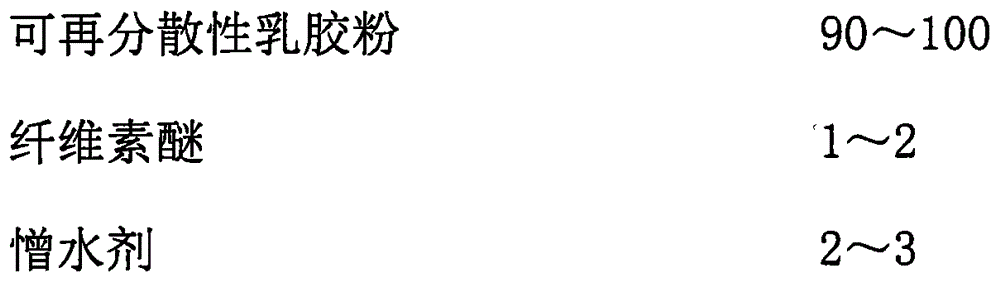

[0034] Paste the waterproof membrane rubber powder described in the present embodiment, it is made up of the component of following weight ratio:

[0035]

Embodiment 2

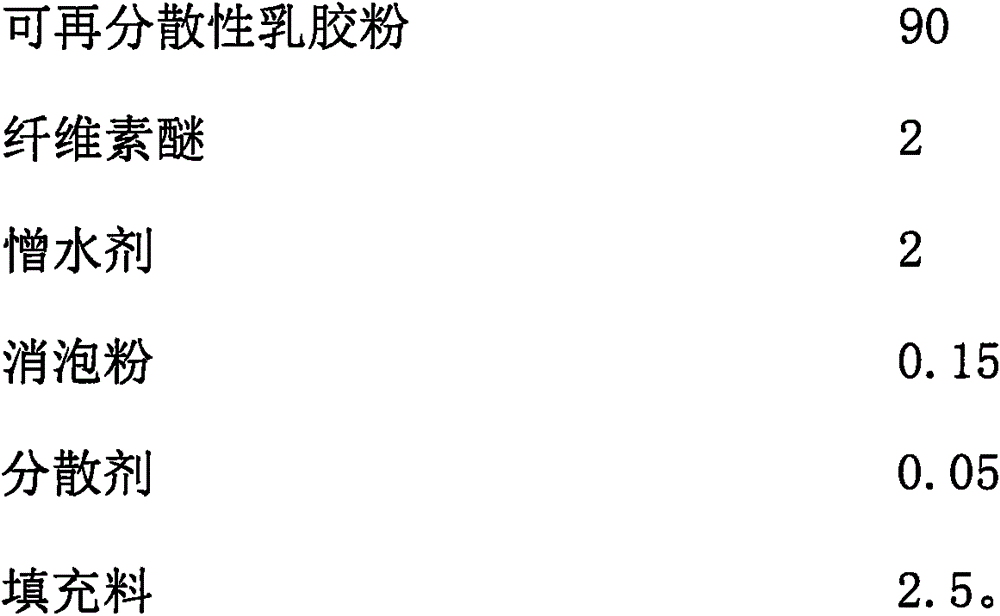

[0037] Paste the waterproof membrane rubber powder described in the present embodiment, it is made up of the component of following weight ratio:

[0038]

Embodiment 3

[0040] Paste the waterproof membrane rubber powder described in the present embodiment, it is made up of the component of following weight ratio:

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com