Preparation method of corrosion-resistant flame-retardant paint

A corrosion-resistant and paint-resistant technology, applied in the paint field, achieves the effects of few steps, mild reaction conditions, and simple and easy-to-operate preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

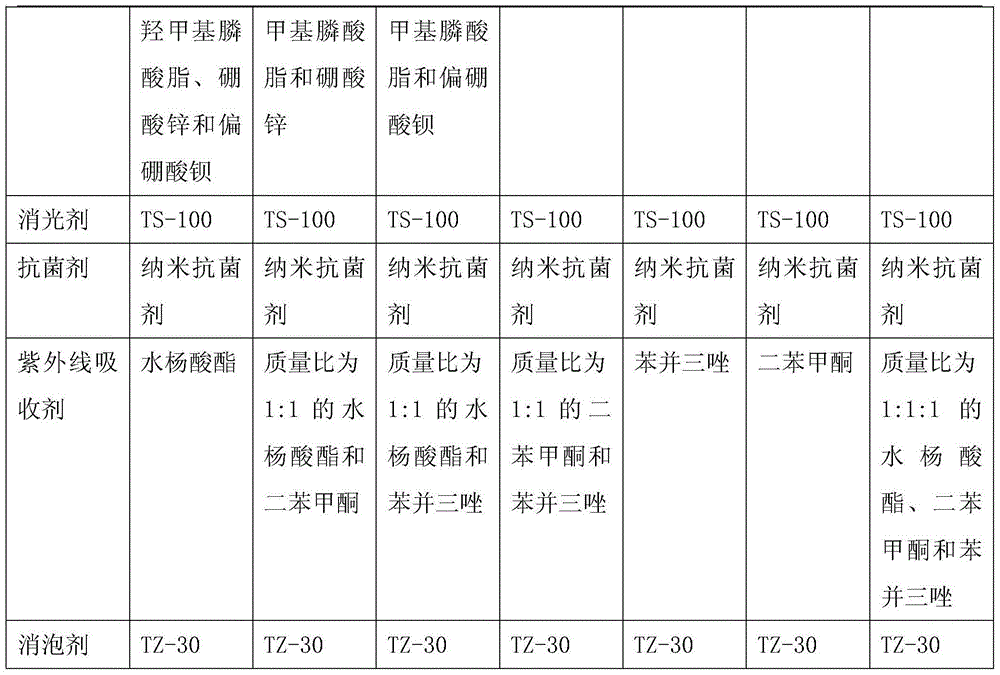

Embodiment 1

[0025] A method for preparing a corrosion-resistant and oil-resistant paint, comprising the following steps: (1) pretreatment: vacuum-drying the main resin at 100°C for 36h, removing water for later use; (2) heating 89g of the pretreated main resin to 50°C, adding 67g of monomer diluent, 1200r / min high-speed stirring for 60min; (3) heating up to 130°C, adding 10g of initiator, 17g of antistatic agent, 17g of flame retardant and 17g of matting agent, and reacting for 3.5h; (4) cooling down to 92 ℃, add 10g of antibacterial agent, 12g of ultraviolet absorber and 1g of defoamer, and react for 2.5h; (5) Slowly cool down to 45°C while stirring, ultrasonically disperse for 20min, and cool down to room temperature.

Embodiment 2

[0027] A method for preparing a corrosion-resistant and oil-resistant paint, comprising the following steps: (1) pretreatment: vacuum-drying the main resin at 100°C for 48h, removing water for later use; (2) heating 101g of the pretreated main resin to 60°C, adding 82g of monomer diluent, 2000r / min high-speed stirring for 90min; (3) heating up to 145°C, adding 15g of initiator, 29g of antistatic agent, 29g of flame retardant and 35g of matting agent, and reacting for 5.5h; (4) cooling down to 95 ℃, add 16g of antibacterial agent, 15g of ultraviolet absorber and 11g of defoamer, react for 3.5h; (5) Slowly cool down to 50℃ while stirring, ultrasonically disperse for 45min, then cool down to room temperature.

Embodiment 3

[0029] A method for preparing a corrosion-resistant and oil-resistant paint, comprising the following steps: (1) pretreatment: vacuum-drying the main resin at 100°C for 42 hours, removing water for later use; (2) heating 99g of the pretreated main resin to 55°C, adding 78g of monomer diluent, 1800r / min high-speed stirring for 80min; (3) heating up to 140°C, adding 13g of initiator, 19g of antistatic agent, 27g of flame retardant and 23g of matting agent, and reacting for 4h; (4) cooling down to 95°C , add 15g of antibacterial agent, 14g of ultraviolet absorber and 7g of defoamer, and react for 3h; (5) Slowly cool down to 45°C while stirring, ultrasonically disperse for 40min, and cool down to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com