Process for purifying reactive dye for ink jet printing and reactive dye ink

A reactive dye and inkjet printing technology, applied in organic dyes, inks, applications, etc., can solve the problems of low divalent salt removal efficiency, high energy consumption, and poor removal effect, and achieve a simple and feasible purification process with low production costs Low, high separation quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The purification preparation of embodiment 1 reactive red C.I.24 (K-2BP)

[0037] The purification preparation process of the reactive red C.I.24 (K-2BP) comprises:

[0038] 1) Reactive Red C.I.24 and deionized water are mixed into an aqueous solution with a concentration of 45g / l, and then the barium chloride aqueous solution with a concentration of 0.1% of the total barium chloride solution dosage is 0.053mol / l is added while stirring to reduce the reaction The relative saturation of the liquid, after stirring for 5 minutes, add BaSO 4 Theoretical precipitation 1% BaSO 4 As a seed crystal and continued to stir for 5 minutes, then the remaining barium chloride aqueous solution was added dropwise at a constant speed within 15 minutes, and the reaction was stirred for 2 hours, so that the BaCl 2 Fully react with the sulfate ion in the reactive red C.I.24 crude dye solution and produce precipitation;

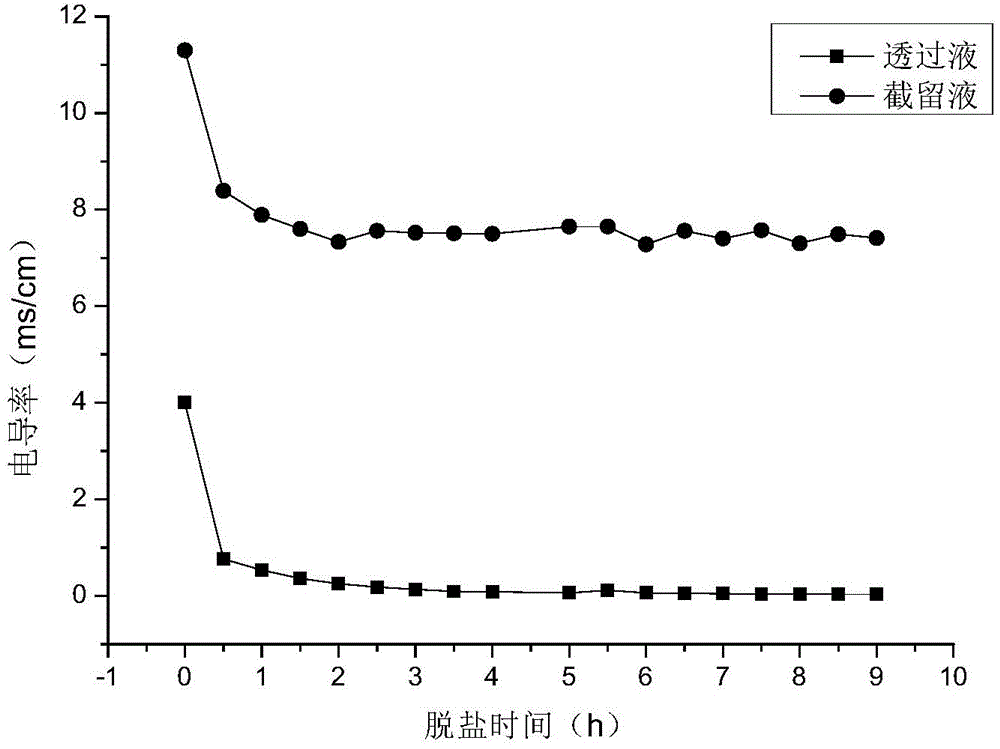

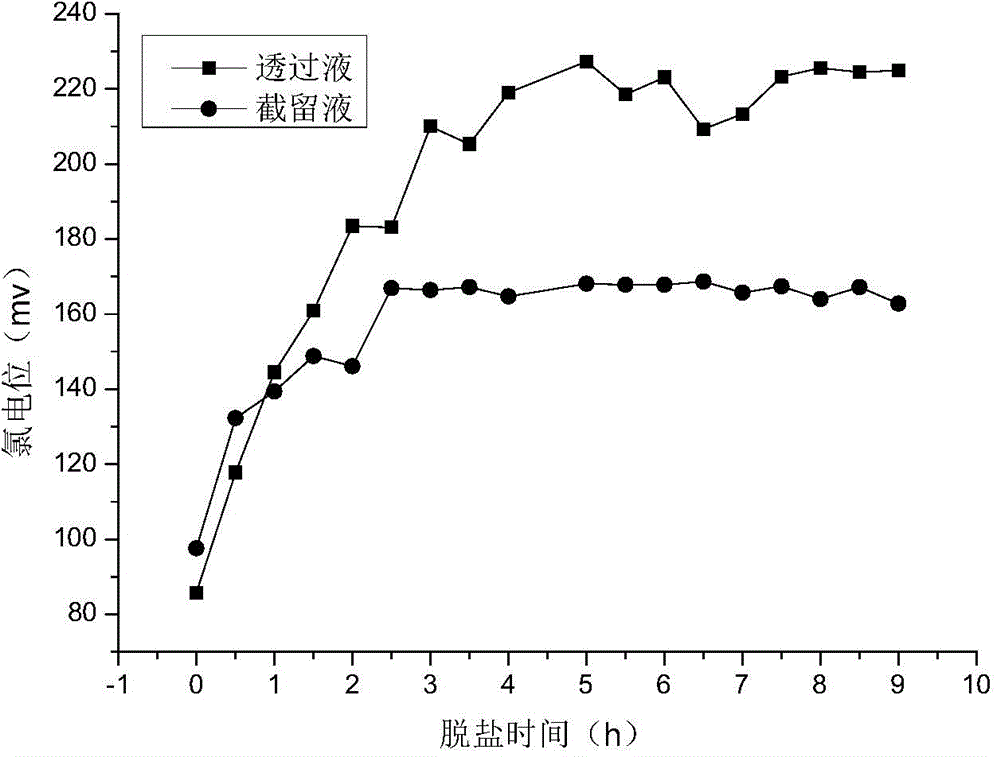

[0039] 2) After the reactive red C.I.24 crude dye solution after th...

Embodiment 2

[0048] The purification preparation of embodiment 2 reactive red C.I.279 (FN-4B)

[0049] The purification preparation process of described active red FN-4B comprises:

[0050] 1) active red FN-4B and deionized water are mixed into the aqueous solution that concentration is 70g / l, then add the barium chloride solution that the concentration of total barium chloride solution consumption 0.1% is 0.106mol / while stirring to reduce reaction The relative saturation of the liquid, after stirring for 5 minutes, add BaSO 4 1% BaSO of theoretical precipitation 4 As a seed crystal and continued to stir for 10 minutes, then the remaining barium chloride solution was added dropwise at a constant speed within 15 minutes, and stirred for 4 hours to make the BaCl 2 Fully react with the sulfate ion in the reactive red FN-4B crude dye solution and produce precipitation;

[0051] 2) After the reactive red FN-4B crude dye solution after the precipitation reaction in step 1) was left to stand ...

Embodiment 3

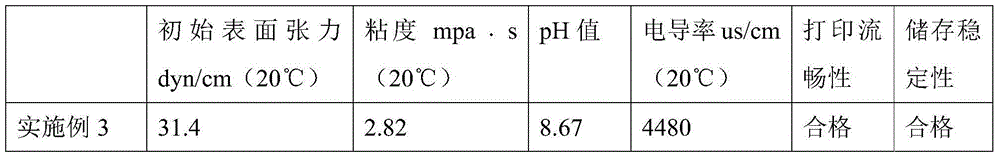

[0061] A kind of reactive red digital inkjet printing dye ink, its weight percentage is composed of: the reactive red dye that makes in the embodiment 1: 30%, polyethylene glycol 200: 8%, glycerol: 8%, 1,5-pentane Diol: 2%, Ethanol: 3%, N-Methylpyrrolidone: 2%, GXL fungicide: 0.2%, Triethanolamine: 0.5%, (U.S. Air Chemicals): 0.2%, Bayer, Germany 0.3%, deionized water: the remaining amount, the above-mentioned components are mixed and stirred at room temperature, and then filtered through 0.65 μm and 0.22 μm filter membranes to obtain the reactive red dye ink. In this embodiment, the polyethylene glycol 200, glycerin, 1,5-pentanediol, and ethanol are all used as moisturizers, Used as a surfactant, CX-100 as a dispersant, and triethanolamine as a pH regulator.

[0062] Table 3 shows the performance test results of the ink prepared in Example 3, wherein: the printing fluency test process is: on the printer based on the Epson piezoelectric nozzle, continuously print the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com