A preparation method for autoclaved aerated concrete blocks produced from antimony ore tailings

A concrete block and autoclaved aeration technology, which is applied in ceramic products, climate sustainability, sustainable waste treatment, etc. , Improve the strength of masonry, prolong the effect of digestion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

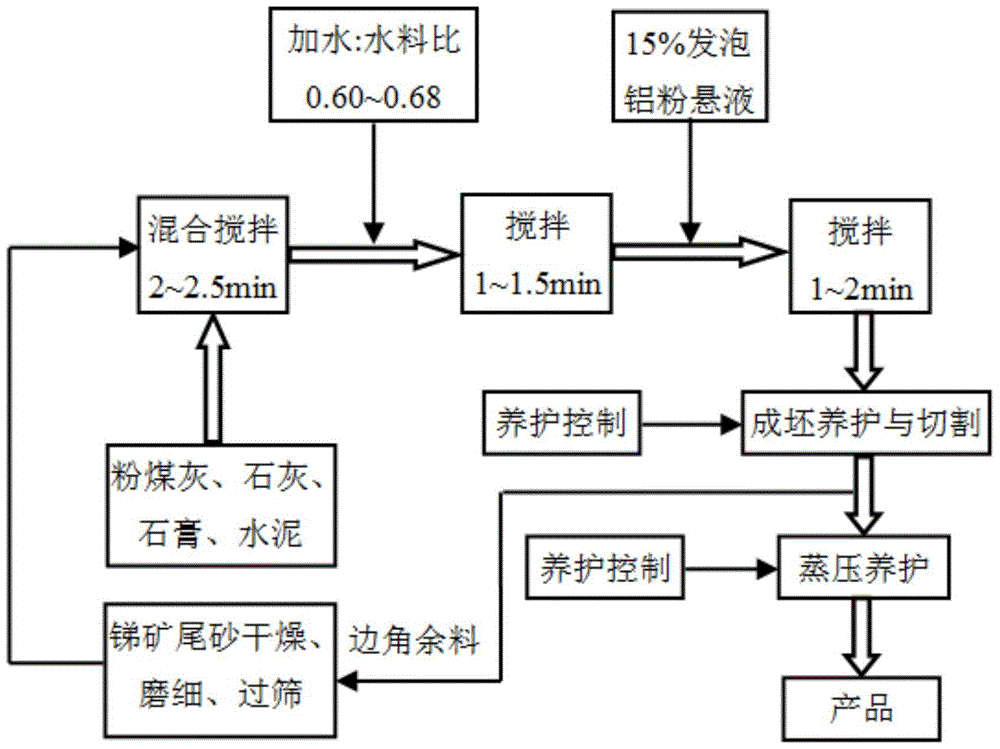

Method used

Image

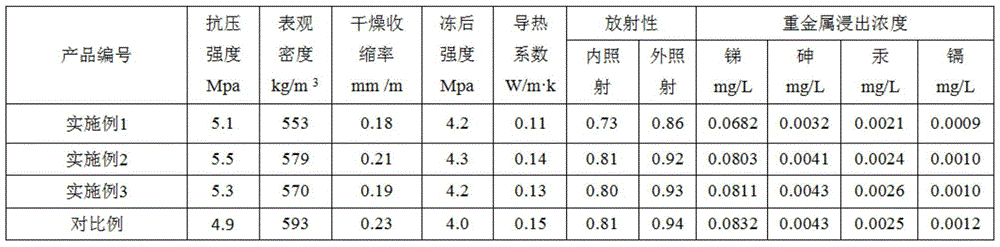

Examples

Embodiment 1

[0031] (1) Take the tailings of a certain antimony ore and form and maintain it into a billet and cut the leftovers into a dryer with a temperature of 130°C to 150°C to dry, and send the dried mixture to a ball mill to grind it finely, and finally pass it through a 0.150mm After being sieved by the sieving machine, it is ready for use.

[0032] (2) According to the preparation process of the autoclaved aerated concrete block of the present invention, respectively weigh antimony ore tailings, fly ash, quicklime powder, gypsum, 425# ordinary Portland cement, Water and foamed aluminum powder (manually adjusted to 15% foamed aluminum powder suspension) for use; then put antimony ore tailings-fly ash-quicklime powder-gypsum-cement into the machine model NJ-160A Stir in a mixer at 300r / min for 2.5min, then add a certain mass of water to the mixer and stir at 500r / min for 1.5min, and finally add foamed aluminum powder suspension and stir at 800r / min for 2min; the mass percentages of ...

Embodiment 2

[0036] (1) Take the tailings of a certain antimony ore and form and maintain it into a billet and cut the leftovers into a dryer with a temperature of 130°C to 150°C to dry, and send the dried mixture to a ball mill to grind it finely, and finally pass it through a 0.150mm After being sieved by the sieving machine, it is ready for use.

[0037] (2) According to the preparation process of the autoclaved aerated concrete block of the present invention, respectively weigh antimony ore tailings, fly ash, quicklime powder, gypsum, 425# ordinary Portland cement, water and foaming Aluminum powder (artificially modulated into 15% foamed aluminum powder suspension) is for use; then the order of antimony ore tailings-fly ash-quicklime powder-gypsum-cement is dropped into the mechanical mixer of NJ-160A and mixed with Stir at 300r / min for 2min, then add a fixed mass of water at about 25°C in the mixer and stir at 500r / min for 1.5min, and finally add foam aluminum powder suspension and st...

Embodiment 3

[0041] (1) Take the tailings of a certain antimony ore and form and maintain it into a billet and cut the leftovers into a dryer with a temperature of 130°C to 150°C to dry, and send the dried mixture to a ball mill to grind it finely, and finally pass it through a 0.150mm After being sieved by the sieving machine, it is ready for use.

[0042] (2) According to the preparation process of the autoclaved aerated concrete block of the present invention, respectively weigh antimony ore tailings, fly ash, quicklime powder, gypsum, 425# ordinary Portland cement, Water and foamed aluminum powder suspension (manually adjusted to 15% foamed aluminum powder suspension) for use; then put antimony ore tailings-fly ash-quicklime powder-gypsum-cement in the order of NJ-160A Stir in a mechanical mixer at 300r / min for 2min, then add a certain mass of water to the mixer and stir at 500r / min for 1.5min, and finally add foamed aluminum powder suspension and stir at 800r / min for 1min; the mass pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com