Method for preparing Pd/CuO composite nanometer porous material by using amorphous alloy for dealloying

An amorphous alloy, nanoporous technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost and low catalytic activity of noble metal catalysts , to achieve the effect of low production cost, small pore size and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for preparing a Pd / CuO composite nanoporous structure material by dealloying an amorphous alloy comprises the following steps:

[0017] Step 1. Prepare the Ti-Cu-Pd amorphous alloy according to the following components and atomic percentages: the content of Ti is 30%, the content of Cu is 65%, and the content of Pd is 5%;

[0018] Step 2, the Ti obtained in step 1 30 Cu 65 PD 5 The amorphous alloy is cut into strips with a thickness of 10 μm-30 μm, a width of 15 mm-20 mm, and a length of 1 cm-3 cm; the strips are ultrasonicated in absolute ethanol for 5 minutes, washed in deionized water and dried in air for later use;

[0019] Step 3, get the Ti obtained by step 2 30 Cu 65 PD 5 Put 0.1g of amorphous alloy strip mass and 46ml of hydrochloric acid aqueous solution with a molar concentration of 1.25M in a closed container, and put it in a 90°C drying oven, keep it warm for 5h, and use deionized water to prepare the sample after the reaction After washing an...

Embodiment 2

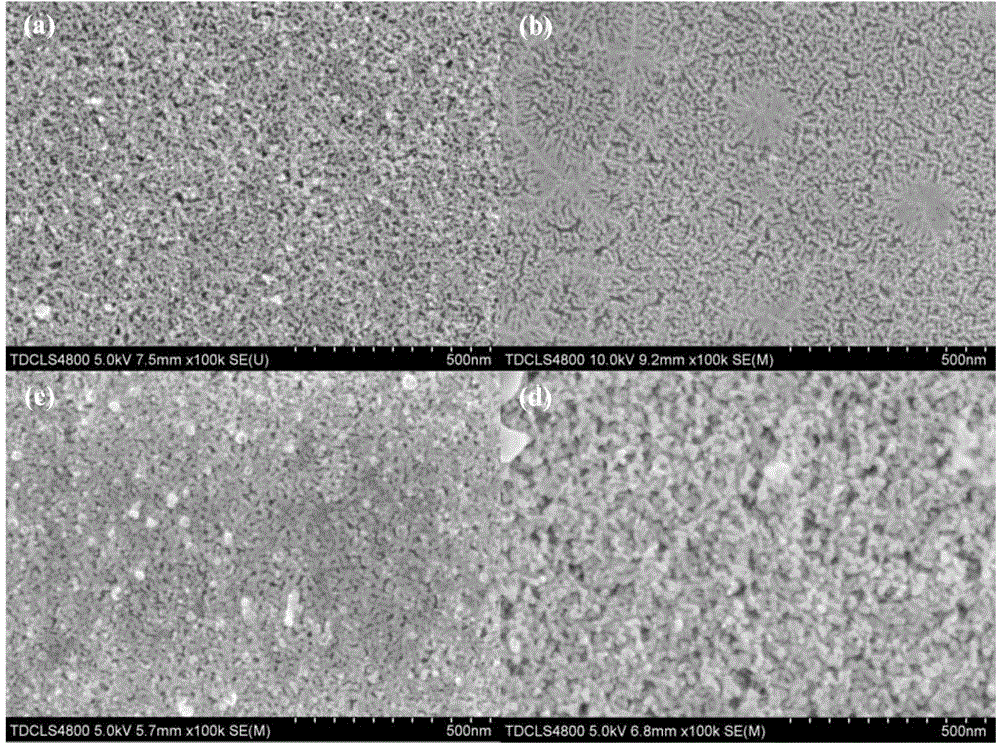

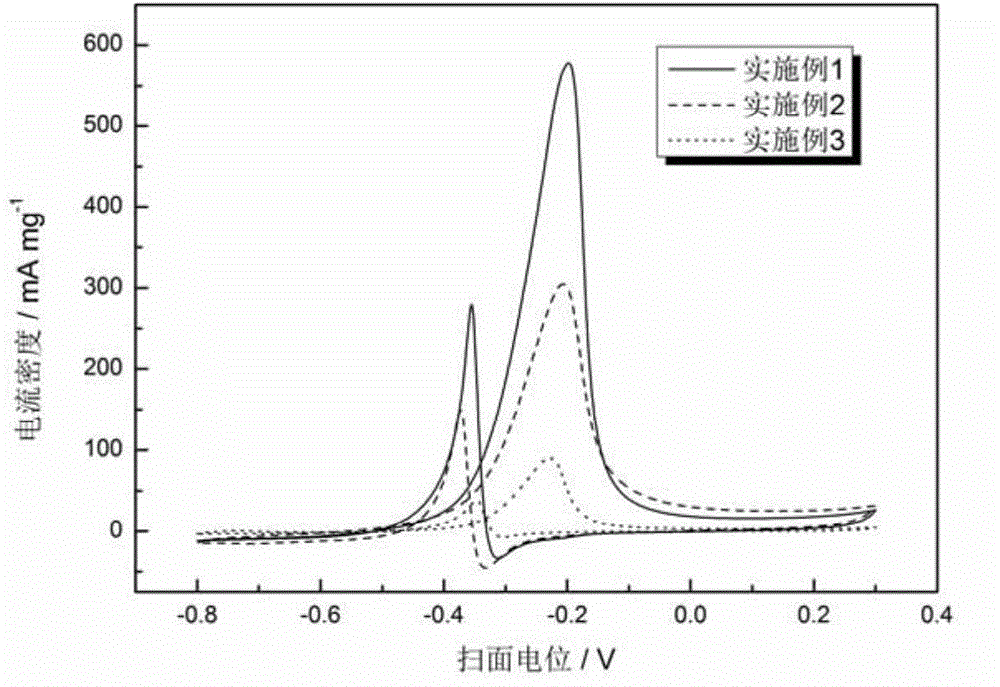

[0023] The preparation process is basically the same as in Example 1, except that in step 3, the molar concentration of the hydrochloric acid aqueous solution is 1.25M, the reaction temperature is 90°C, and the reaction time is 5h. figure 1 (b) shows the SEM figure of the Pd / CuO composite nanoporous structure material prepared in this embodiment 2, figure 2 The dotted line in shows the cyclic Fuan curve of the Pd / CuO composite nanoporous structure material prepared in Example 2.

Embodiment 3

[0025] The preparation process is basically the same as that of Example 1, except that in step 3, the molar concentration of the hydrochloric acid aqueous solution is 5M, the reaction temperature is 90°C, and the reaction time is 5h. figure 1 (c) shows the SEM figure of the Pd / CuO composite nanoporous structure material prepared in this embodiment 3, figure 2 The dotted line in the figure shows the cyclic Fuan curve of the Pd / CuO composite nanoporous structure material prepared in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com