Preparation method of modified polyvinylidene fluoride hybrid film and application thereof

A polyvinylidene fluoride, hybrid membrane technology, applied in chemical instruments and methods, separation methods, membrane technology and other directions, to achieve the effect of mild preparation process conditions and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of preparation method of the polyvinylidene fluoride hybrid film of modification, comprises the following steps:

[0030] Step 1. Preparation of fluorine-containing amphiphilic membrane modifier: Add 4.7g of hexafluorobutyl acrylate monomer into a three-necked flask with a stirrer, add 80mL of dehydrated ethanol, and mechanically stir for 30 minutes under nitrogen protection , and the reaction temperature was set to 70°C. After the oxygen in the system is eliminated, add 164mg of azobisisobutyronitrile to initiate, and react at 70°C for 2 hours, then use a constant pressure dropping funnel to add acrylic acid ethanol solution drop by drop. The acrylic acid ethanol solution is dissolved in 20ml of acrylic acid Anhydrous ethanol was obtained, and the reaction was continued for 8 hours. After the reaction, the reaction solution was extracted three times with n-heptane to remove unreacted monomers and small molecular substances, and then freeze-dried t...

Embodiment 2

[0034] Embodiment 2: a kind of preparation method of the polyvinylidene fluoride hybrid film of modification, comprises the following steps:

[0035] Step 1, prepare fluorine-containing amphiphilic membrane modifier, same as Example 1;

[0036] Step 2. Preparation of fluorine-containing amphiphilic membrane composite modifier solution: Weigh 0.8g of the polyhexafluorobutyl acrylate-polyacrylic acid copolymer prepared in step 1, dissolve it in 3.0g of N-methylpyrrolidone, and stir Add 204 mg of butyl titanate dropwise, stir at 60°C for 10 hours to form an orange homogeneous phase, and a modifier solution in which polyhexafluorobutyl acrylate-polyacrylic acid copolymer and butyl titanate are dissolved is the fluorine-containing amphiphile Membrane composite modifier solution.

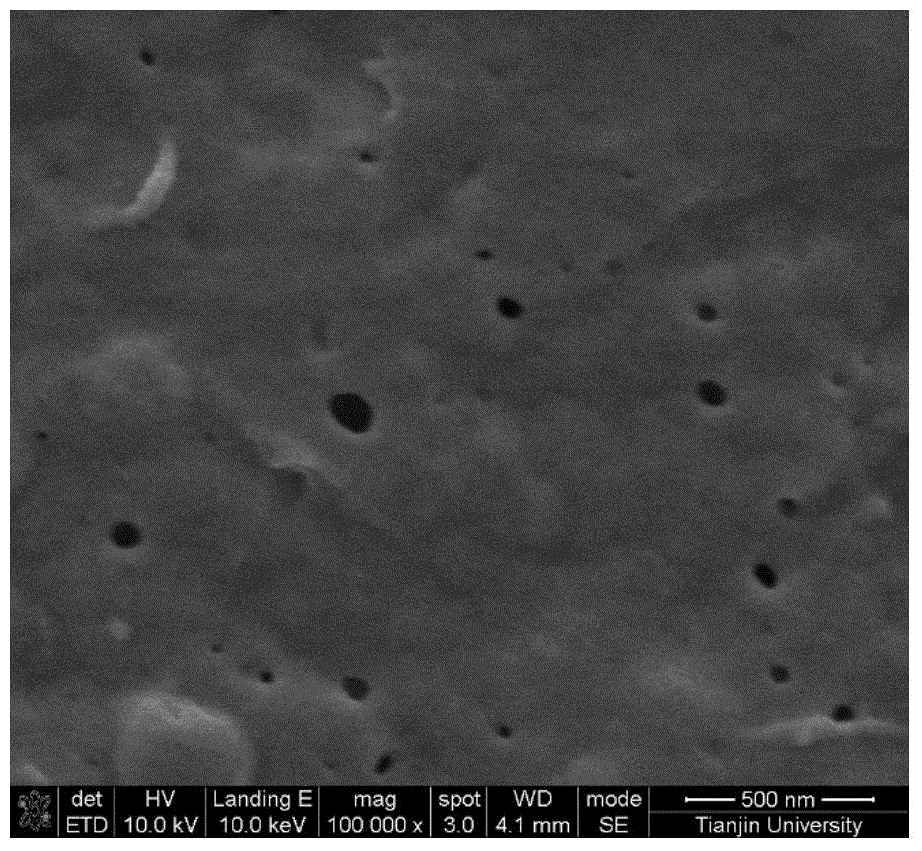

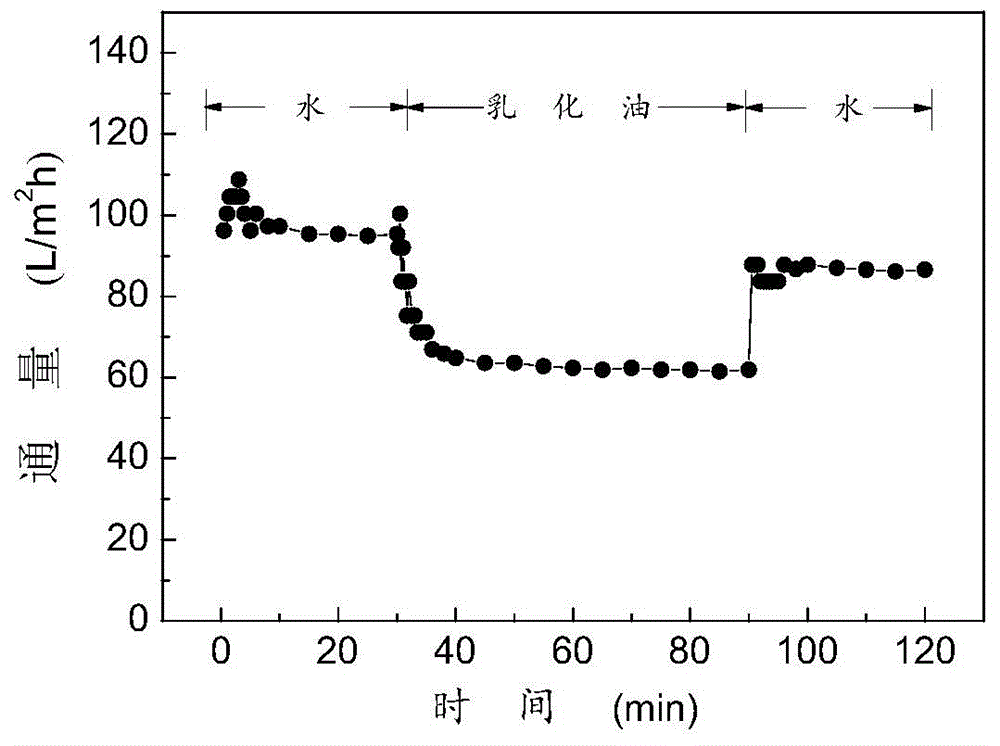

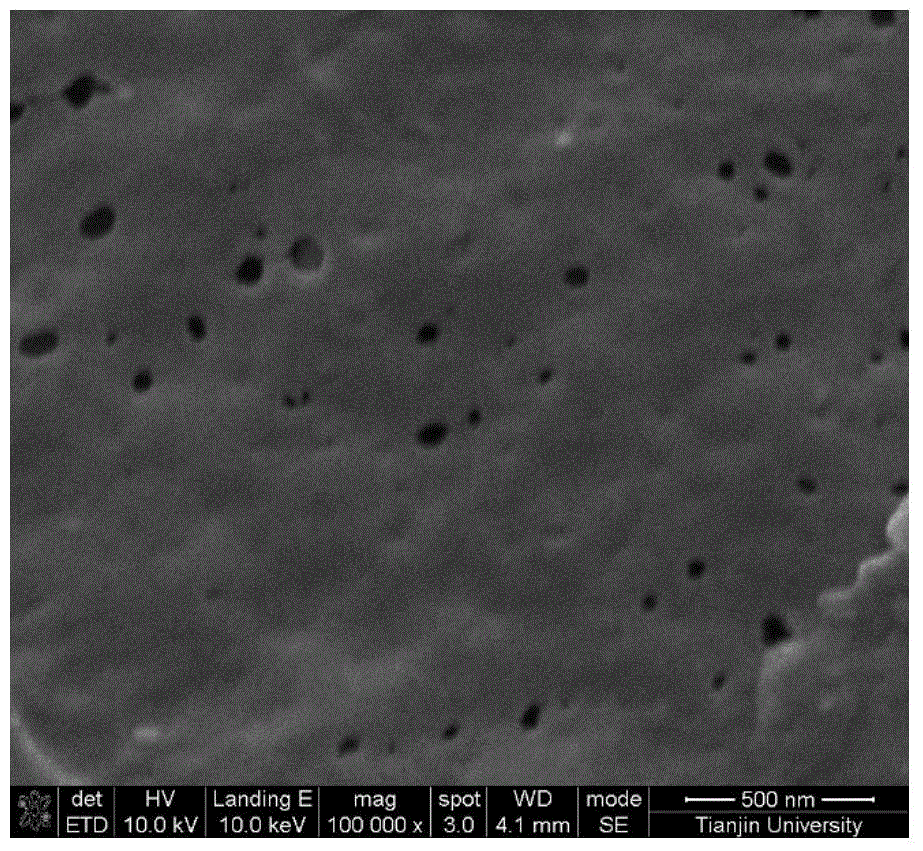

[0037] Step 3, preparing a modified polyvinylidene fluoride hybrid film, the same as in Example 1, wherein, in the water bath, butyl titanate is hydrolyzed and polycondensed to form titanium dioxide nano...

Embodiment 3

[0039] Embodiment 3: a kind of preparation method of the polyvinylidene fluoride hybrid film of modification, comprises the following steps:

[0040] Step 1, prepare fluorine-containing amphiphilic membrane modifier, same as Example 1;

[0041] Step 2. Preparation of fluorine-containing amphiphilic membrane composite modifier solution: Weigh 0.8g of the polyhexafluorobutyl acrylate-polyacrylic acid copolymer prepared in step 1, dissolve it in 3.0g of N-methylpyrrolidone, and stir Add 304 mg of butyl titanate dropwise, stir at 60°C for 10 hours to form an orange homogeneous phase, and a modifier solution in which polyhexafluorobutyl acrylate-polyacrylic acid copolymer and butyl titanate are dissolved is the fluorine-containing amphiphile Membrane composite modifier solution.

[0042] Step 3, preparing a modified polyvinylidene fluoride hybrid membrane, the same as in Example 1, wherein the butyl titanate in the water bath is hydrolyzed and polycondensed to form titanium dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com