Method for preparing nano-compound antibacterial dressing

A nano-composite, antibacterial agent technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of material spinning, film drawing difficulties, large R&D investment, slow antibacterial effect, etc., and achieve good UV shielding performance and low manufacturing cost. Inexpensive, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

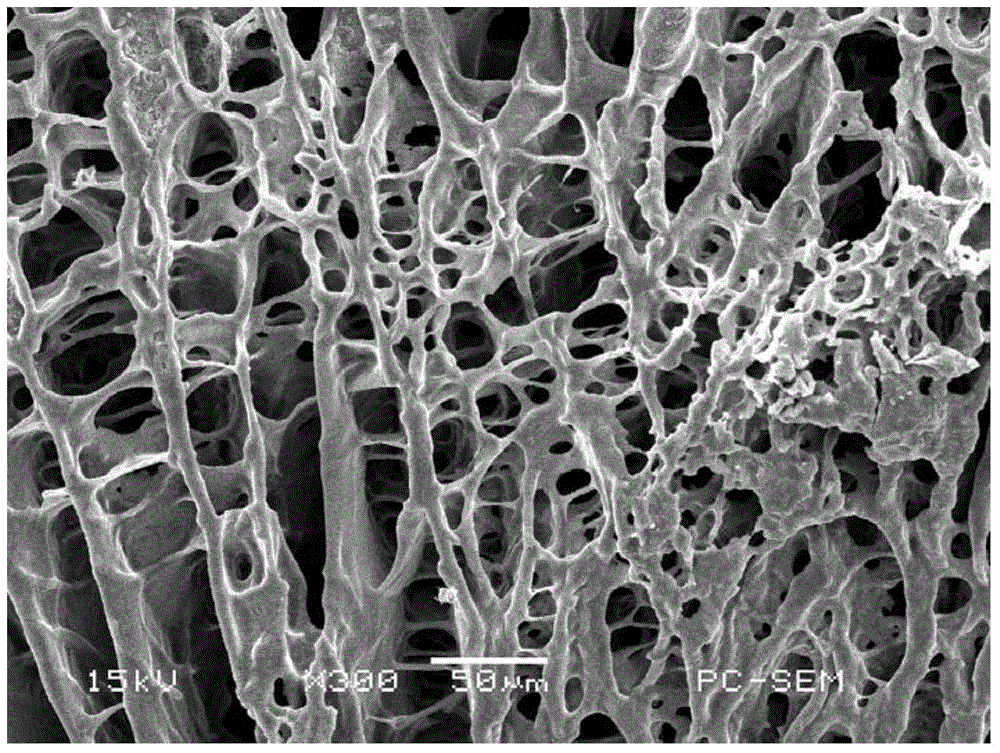

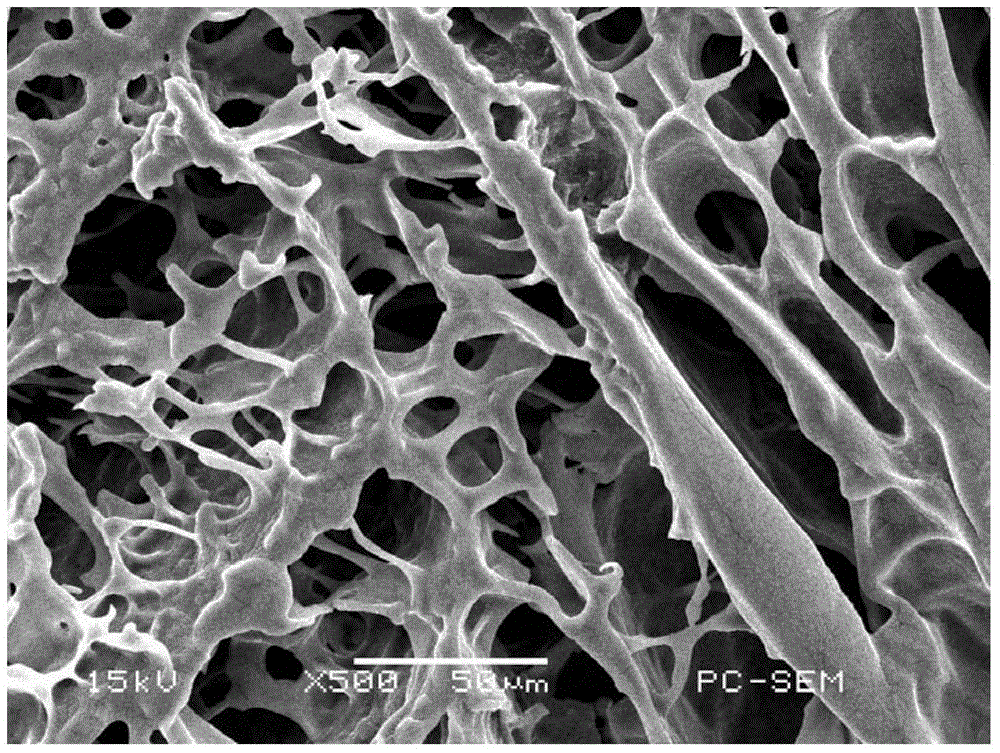

Image

Examples

Embodiment 1

[0029] (1) Preparation of nanocomposite antibacterial agent: silicon dioxide, titanium dioxide, zinc oxide, and magnesium oxide are dissolved in deionized water in a molar ratio of 40:20:15:25, and the concentration is prepared into a 5% aqueous solution; Add 0.5% cetyltrimethylammonium bromide as a surfactant and 1% Tween 20 as an emulsifier; transfer the solution to a three-necked flask, and stir for 2 hours at a temperature of T=40°C to obtain a uniform antibacterial agent dispersion;

[0030] (2) Preparation of polymer solution: directly dissolve the water-soluble polymer polyoxyethylene in deionized water, prepare an aqueous solution with a concentration of 3%, stir magnetically for 24 hours, and obtain a uniform polymer solution;

[0031] (3) Preparation of composite antibacterial dressing: Mix the polymer solution and the nanocomposite antibacterial agent at a mass ratio of 8:2, mechanically stir for 12 hours, and leave the solution ultrasonically to remove air bubbles ...

Embodiment 2

[0033] (1) Preparation of nano-composite antibacterial agent: silicon dioxide, titanium dioxide, zinc oxide, and magnesium oxide are dissolved in deionized water in a molar ratio of 40:20:15:25, and are mixed with an 8% aqueous solution; Add 0.5% cetyltrimethylammonium bromide as a surfactant and 1% Tween 20 as an emulsifier; transfer the solution to a three-necked flask, and stir for 2 hours at a temperature of T=40°C to obtain a uniform antibacterial agent dispersion;

[0034] (2) Preparation of polymer solution: directly dissolve the water-soluble polymer polyoxyethylene in deionized water, prepare an aqueous solution with a concentration of 3%, stir magnetically for 24 hours, and obtain a uniform polymer solution;

[0035] (3) Preparation of composite antibacterial dressing: Mix the polymer solution and the nanocomposite antibacterial agent at a mass ratio of 8:2, mechanically stir for 12 hours, and leave the solution ultrasonically to remove air bubbles in the solution; ...

Embodiment 3

[0037] (1) Preparation of nano-composite antibacterial agent: silicon dioxide, titanium dioxide, zinc oxide, and magnesium oxide are dissolved in deionized water in a molar ratio of 40:20:15:25, and are mixed with an 8% aqueous solution; Add 0.5% cetyltrimethylammonium bromide as a surfactant and 1.5% Tween 20 as an emulsifier; transfer the solution to a three-necked flask and stir for 2 hours at a temperature of T=60°C to obtain a uniform antibacterial agent dispersion;

[0038] (2) Preparation of polymer solution: directly dissolve the water-soluble polymer polyoxyethylene in deionized water, prepare an aqueous solution with a concentration of 3%, stir magnetically for 24 hours, and obtain a uniform polymer solution;

[0039] (3) Preparation of composite antibacterial dressing: Mix the polymer solution and the nanocomposite antibacterial agent at a mass ratio of 8:2, mechanically stir for 12 hours, and leave the solution ultrasonically to remove air bubbles in the solution; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com