High-strength self-repair ultraviolet shielding conductive PVA hydrogel and preparation method thereof

A self-healing and external shielding technology, applied in the field of new high-strength self-healing PVA hydrogel, can solve the problem of single function, and achieve the effect of improving strength, excellent UV absorption, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

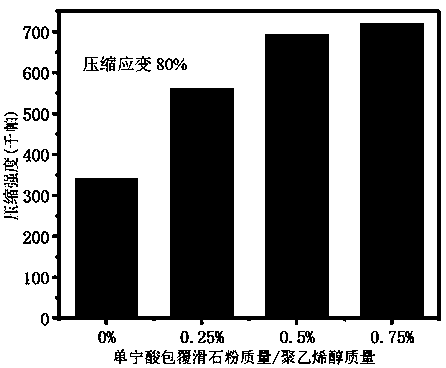

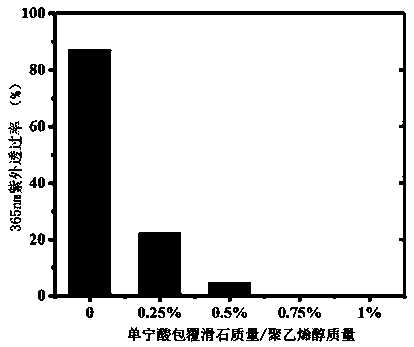

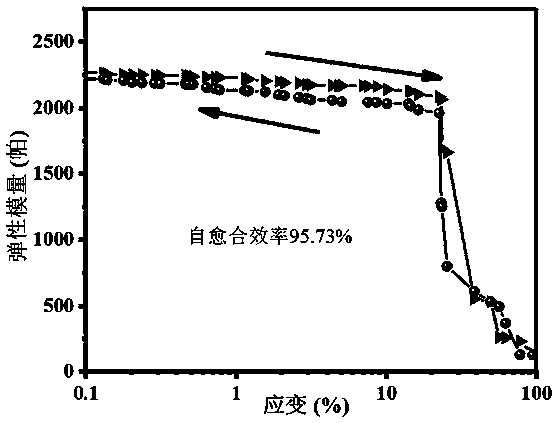

Embodiment 1

[0022] (1) Preparation of tannic acid coated talc powder:

[0023] First, weigh 0.2 g of talcum powder and add it to 100 ml of water. After being uniformly dispersed by ultrasonic treatment, add 0.2 g of tannic acid, adjust the pH value of the solution to 8, and stir and react at 20°C for 8 hours. Finally, the talcum powder / tannic acid complex was separated in a centrifuge at 10,000 rpm.

[0024] (2) Preparation of high-strength self-healing UV-shielding conductive PVA hydrogel:

[0025] Add 0.4 g of talcum powder / tannic acid complex into 20 ml of ethylene glycol / water solution (the volume ratio of ethylene glycol to water is 1:1), and disperse evenly by ultrasonic treatment, then add 2 g of polyvinyl alcohol, heat To 95 ° C to completely dissolve the PVA. The solution was placed in a mold, then frozen in liquid nitrogen for half an hour, taken out and then thawed at room temperature for 3 hours, and finally added to a 0.1mol / L aluminum ion solution and soaked for 0.5 hours ...

Embodiment 2

[0027] (1) Preparation of tannic acid coated talc powder:

[0028] First, weigh 0.3 g of talcum powder and add it to 100 ml of water. After being uniformly dispersed by ultrasonic treatment, add 0.3 g of tannic acid, adjust the pH value of the solution to 8, and stir and react at 20°C for 8 hours. Finally, the talcum powder / tannic acid complex was separated in a centrifuge at 10,000 rpm.

[0029] (2) Preparation of high-strength self-healing UV-shielding conductive PVA hydrogel:

[0030] Add 0.6 g of talcum powder / tannic acid complex into 20 ml of ethylene glycol / water solution (the volume ratio of ethylene glycol to water is 1:1), disperse evenly by ultrasonic treatment, then add 3 g of polyvinyl alcohol, heat To 95 ° C to completely dissolve the PVA. Put the solution into a mold, freeze it in liquid nitrogen for half an hour, take it out and thaw it at room temperature for 3 hours, and finally add 0.1mol / l aluminum ion solution and soak it for 0.5 hours to prepare PVA hydr...

Embodiment 3

[0032] (1) Preparation of tannic acid coated talc powder:

[0033] First, weigh 0.4 g of talc powder and add it to 100 ml of water. After being uniformly dispersed by ultrasonic treatment, 0.4 g of tannic acid was added, and the pH value of the solution was adjusted to 8, and the reaction was stirred at 20°C for 8 hours. Finally, the talcum powder / tannic acid complex was separated in a centrifuge at 10,000 rpm.

[0034] (2) Preparation of high-strength self-healing UV-shielding conductive PVA hydrogel:

[0035] Add 0.8 g of talcum powder / tannic acid complex to 20 ml of ethylene glycol / water solution (the volume ratio of ethylene glycol to water is 1:1), disperse evenly by ultrasonic treatment, then add 4 g of polyvinyl alcohol, heat To 95 ° C to completely dissolve the PVA. Put the solution into a mold, freeze it in liquid nitrogen for half an hour, take it out and thaw it at room temperature for 3 hours, and finally add 0.1mol / l aluminum ion solution and soak it for 0.5 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com