Granular silicon dioxide electrolyte and storage battery

A silicon dioxide and electrolyte technology, applied in secondary batteries, lead-acid batteries, circuits, etc., can solve the problems of easy softening and falling off of positive active materials, low utilization rate of battery active materials, uneven distribution of electrolytes, etc. The effect of suppressing thermal runaway, reducing self-discharge, and uniform current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

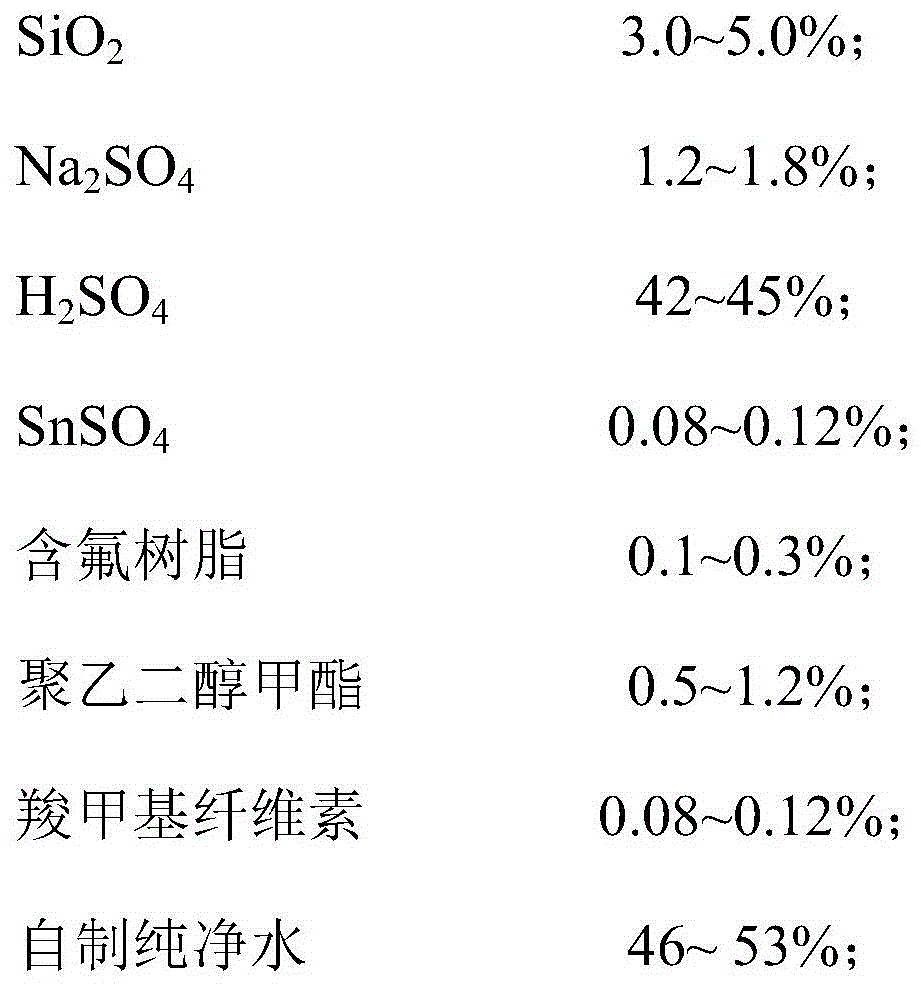

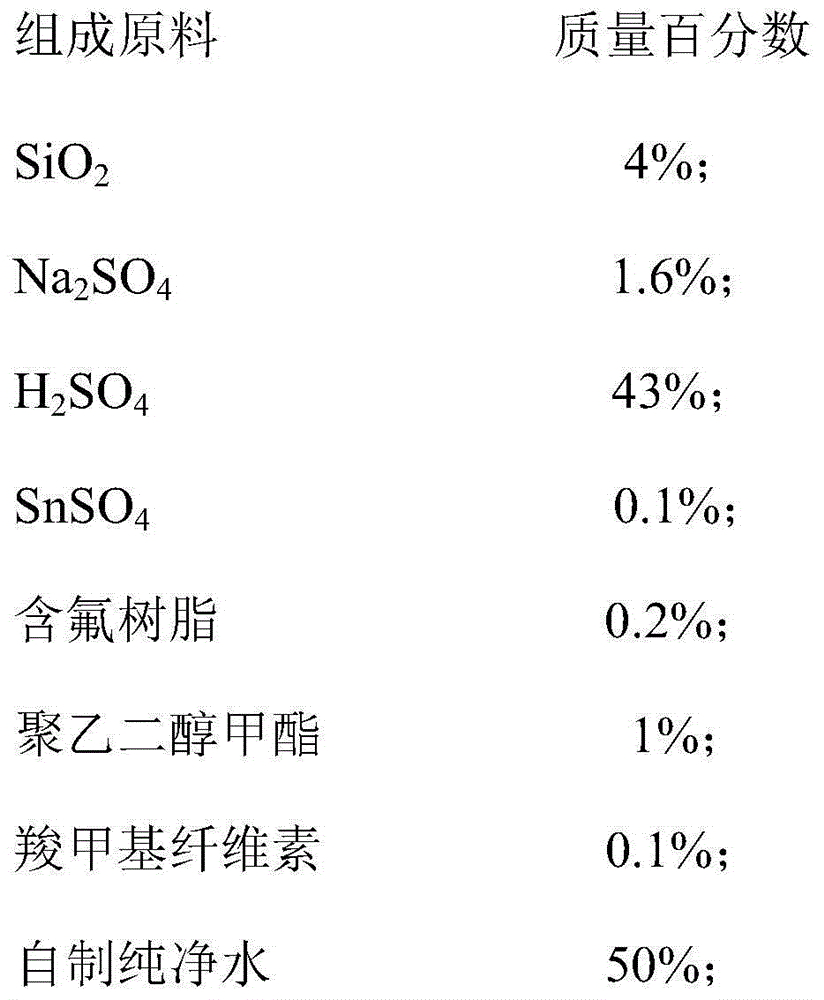

[0014] Embodiment: a kind of granular silicon dioxide electrolytic solution, the composition raw material ratio of described electrolytic solution is by weight percentage:

[0015]

[0016] where the SiO 2 The particles include 60% of 12um, 30% of 30um, and 10% of 50um; the density of the sulfuric acid aqueous solution is 1.35g / ml.

[0017] A storage battery, the electrolyte of which is the above-mentioned granular silicon dioxide electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com