A kind of dual-functional conductive silver paste for touch screen and its preparation method and application

A conductive silver paste and dual-function technology, which is applied in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of cumbersome procedures, reduced production costs, and low utilization of materials and working hours. Achieve the effects of high adhesion strength, high yield rate, and complete functionality of the silver electrode wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

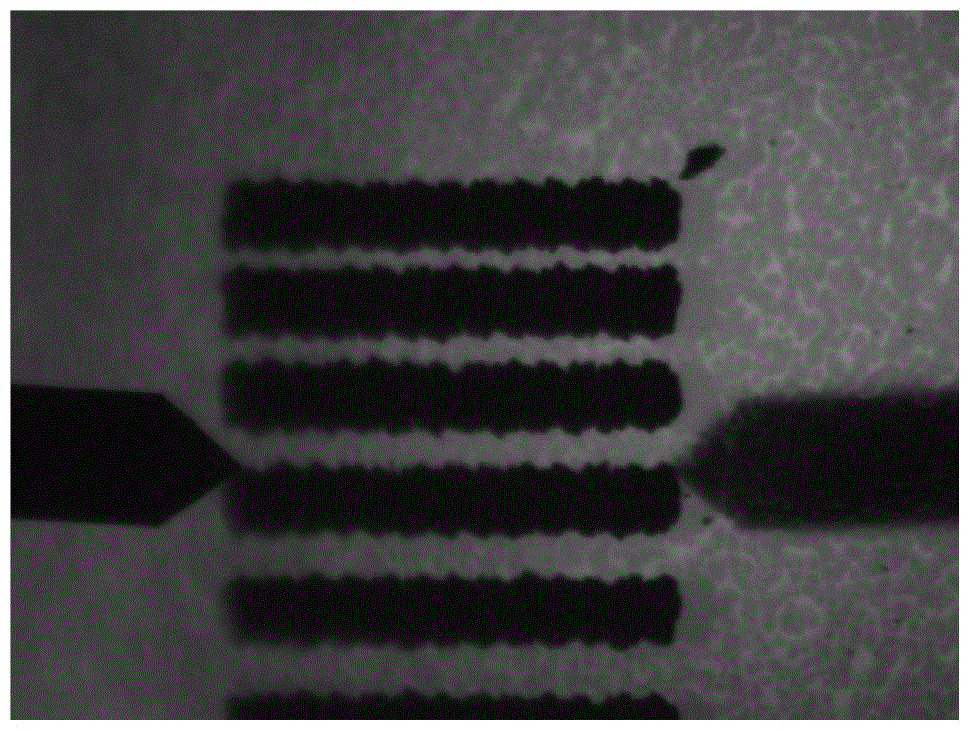

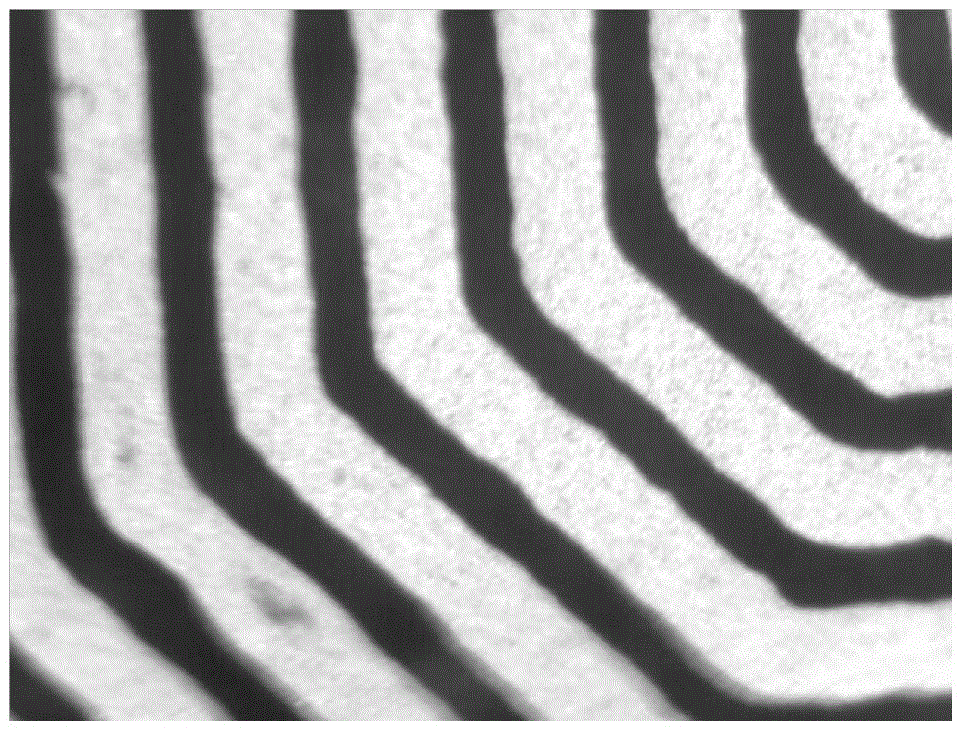

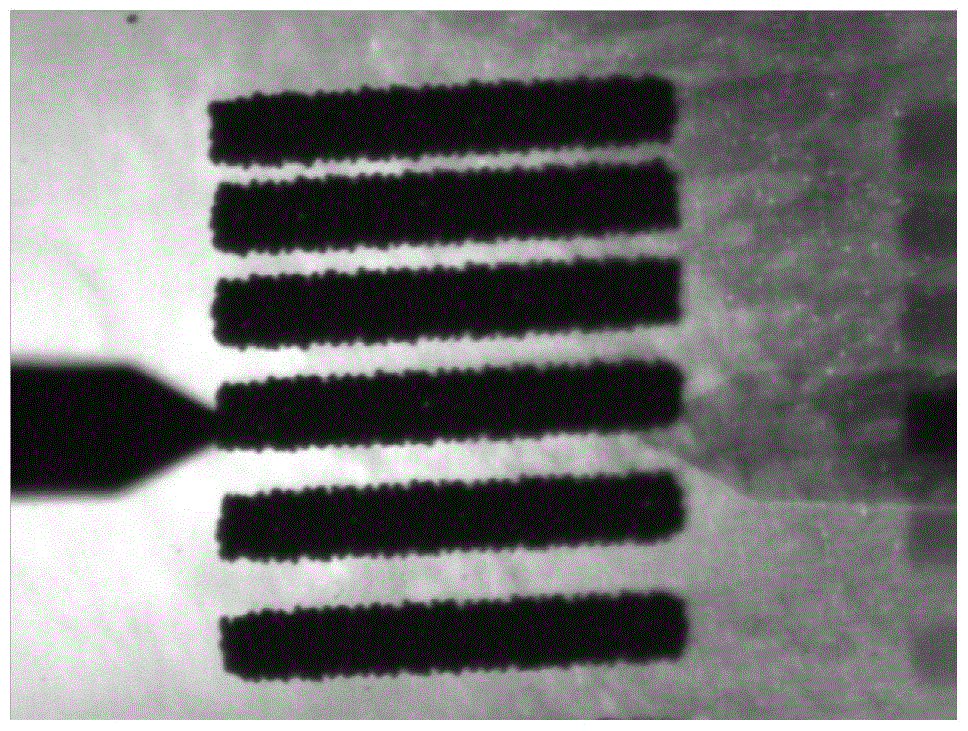

Image

Examples

preparation example Construction

[0035] The preparation method of the conductive paste of the embodiment of the present invention comprises the following steps:

[0036] (1) preparing an organic carrier, further comprising the steps of:

[0037] (1-1) The molecular weight is lower than 600 terminal hydroxyl linear alcohol polyester as the monomer of the structural resin, in N 2 Heat and stir under air protection, react polyester and TDI at 40-60°C for 1-1.5 hours, add organic solvent, after the prepolymer is dissolved, add chain extender R(OH) dropwise x , and raise the reaction temperature to 70-90°C, stop the reaction with alcohol when the viscosity of the system reaches the required value, and obtain a modified polyurethane with a number-average molecular weight of 8000-12000;

[0038] (1-2) Modified polyurethane, latent curing agent and diluent are dispersed by a high-speed disperser to prepare an organic vehicle.

[0039] (2) preparing a dual-functional conductive silver paste for a touch screen, furth...

Embodiment 1

[0042] in N 2 Heating and stirring under the protection of air, react the hydroxy-terminated neopentyl alcohol polyester and TDI at 40°C for 1.25 hours, add tetrahydrofuran / tert-butyl methyl ether (V:V=3:1), after the prepolymer is dissolved, drop Add chain extender pentaerythyl glycol, and raise the reaction temperature to 80°C, stop the reaction with alcohol when the viscosity of the system reaches the required value, and obtain a modified polyurethane with a number average molecular weight of 8000;

[0043] The latent curing agent blocked polyisocyanate (Desmodur BL) was added to the modified polyurethane with a molecular weight of 8000 at an active hydroxyl equivalent ratio of 1:1, and dibutyltin dilaurate with a curing agent of 1wt‰, and diluent DBE / 150#( V:V=7:3), the organic vehicle is prepared after being dispersed by a high-speed disperser.

[0044] Weigh raw materials according to the following mass percentage: 73% bulk density is 2.0g / cm 3 , The tap density is 4.6...

Embodiment 2

[0046] in N 2 Heat and stir under the protection of air, react the hydroxyl-terminated neopentyl alcohol polyester and TDI at 50°C for 1 hour, add tetrahydrofuran / dimethylformamide (V:V=2:1), after the prepolymer is dissolved, Add the chain extender trimethylolpropane dropwise, raise the reaction temperature to 70°C, stop the reaction with alcohol when the viscosity of the system reaches the required value, and obtain a modified polyurethane with a number average molecular weight of 10,000;

[0047] The latent curing agent blocked polyisocyanate (Desmodur BL) was added to the modified polyurethane with a molecular weight of 10000 at an active hydroxyl equivalent ratio of 1.4:1, and dibutyltin dilaurate with a curing agent of 1wt‰, and diluent DBE / 70#( V:V=7:3), the organic vehicle is prepared after being dispersed by a high-speed disperser.

[0048] Weigh raw materials according to the following mass percentage: 60% bulk density is 1.1g / cm 3 , The tap density is 3.2g / cm 3 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com