Method for measuring phosphorus in silicon iron by using photometric method

A photometric method and ferrosilicon technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of difficult control of sample dissolution conditions, large amount of perchloric acid, unstable measurement data, etc., achieve stable measurement results, increase service life, The effect of enhancing the dissolving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

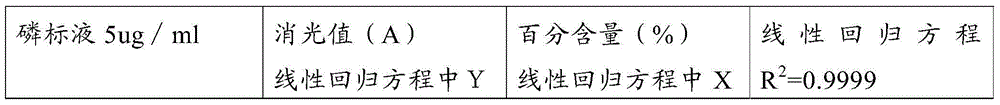

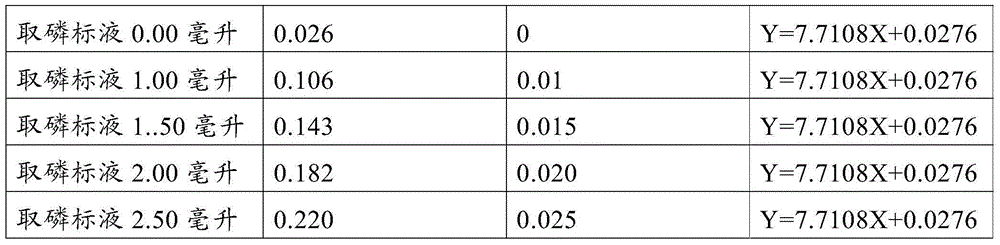

[0038]

[0039]

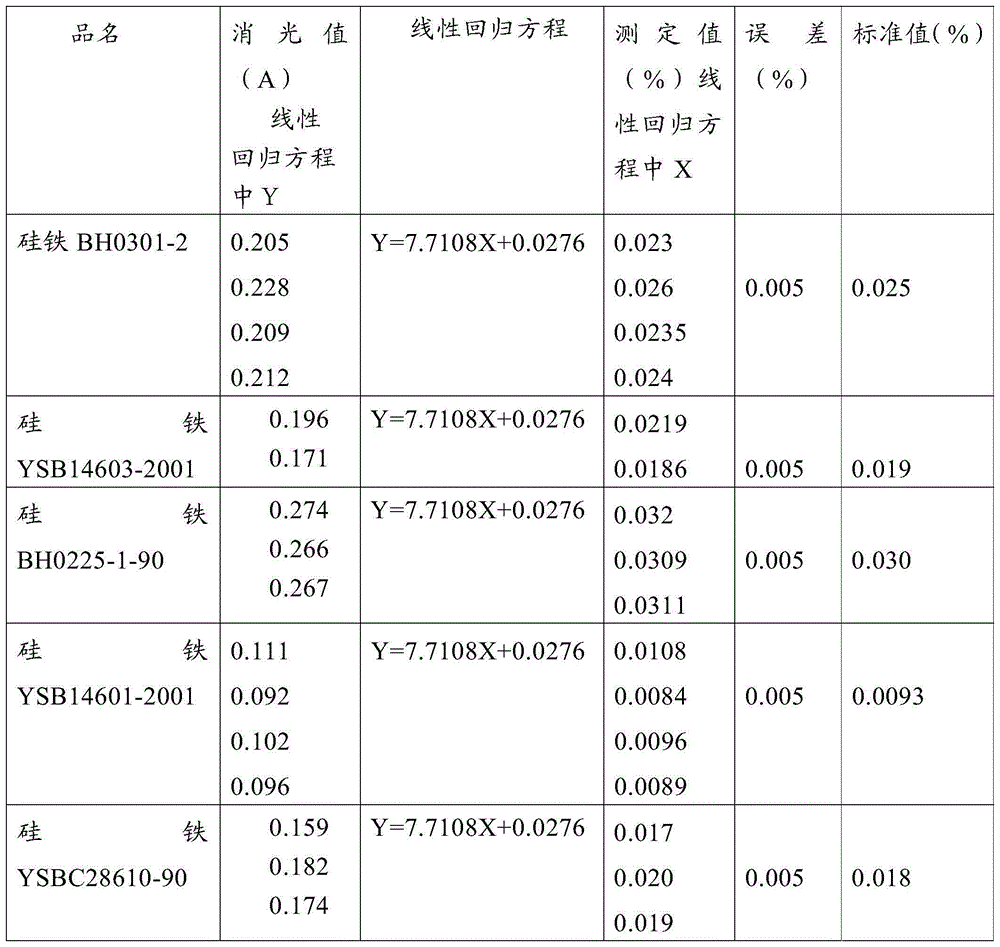

[0040] 7. Sample analysis control:

[0041]

[0042] It can be seen from the above table that after improvement, the data obtained by using the phosphorus-molybdenum blue photometric method to determine the phosphorus content in ferrosilicon is accurate, and the operation process is short, fast and efficient.

[0043]Through this method, the phosphorus content in ferrosilicon can be accurately determined. Compared with the original method, the drug consumption and labor cost are saved, the operation time is greatly shortened, and the energy consumption is reduced. By transferring the beaker and using sodium nitrite, the measurement data is accurate and reliable, and the application in production has achieved good results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com