Mutual locking type positioning bolt component

A positioning bolt and stop technology, applied in the direction of bolts, threaded fasteners, screws, etc., can solve the problems of complex mechanical structure and multi-unit design, large avoidance space, etc., to eliminate cold welding phenomenon, good stop effect, Easy to use and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

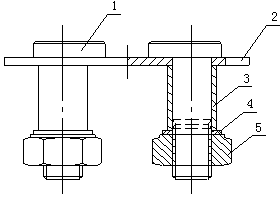

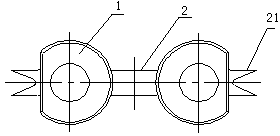

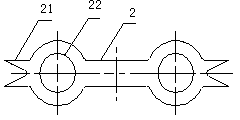

[0017] A mutual stop positioning bolt assembly, comprising two D-shaped head bolts 1 and a stop positioning pad 2, the D-shaped head bolt 1 is provided with a bolt head gap 11, and the stop positioning pad 2 is provided with two Bolt hole 22, the outside of the bolt hole 22 of stop positioning pad 2 is provided with stop positioning reed 21; the bolt rod of D-shaped head bolt 1 is provided with bushing 3, and bushing 3 prevents D-shaped head bolt 1 from being installed body directly intervenes. The D-shaped head bolt passes through the stopper pad 2 and then puts on the bushing 3, then penetrates the installation base and the fastener to be installed, installs the washer 4 and screws on the nut 5, and the base to be installed and the fastener are installed Stop screwing in the nut 5 when there is no axial movement but still rotatable. At this time, adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com