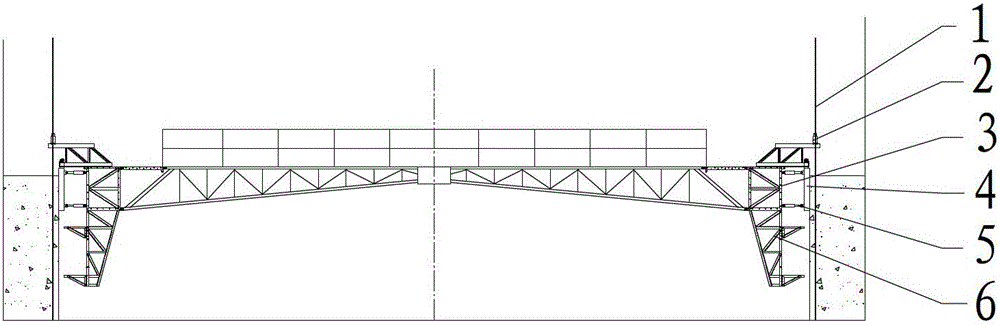

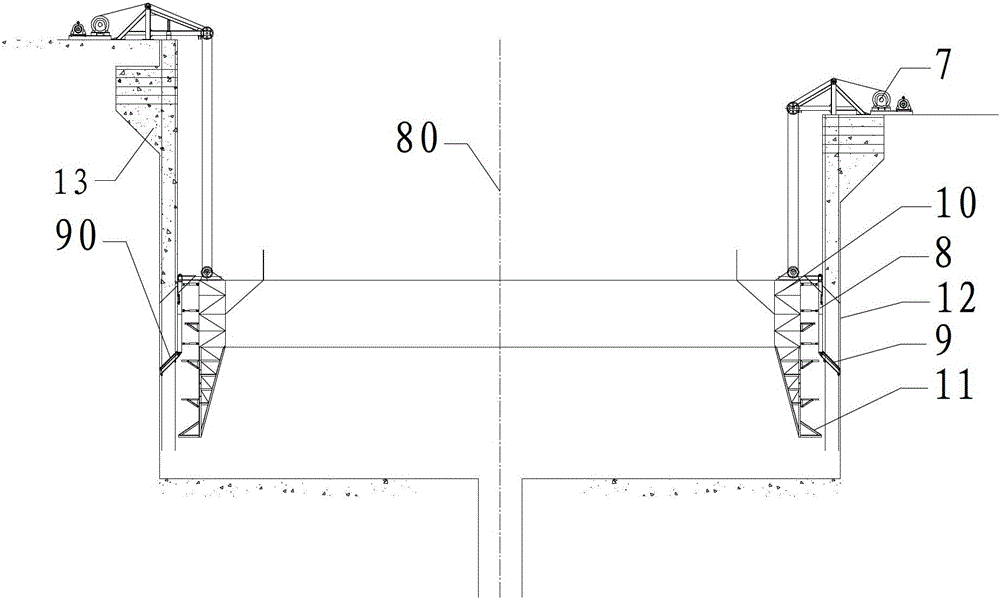

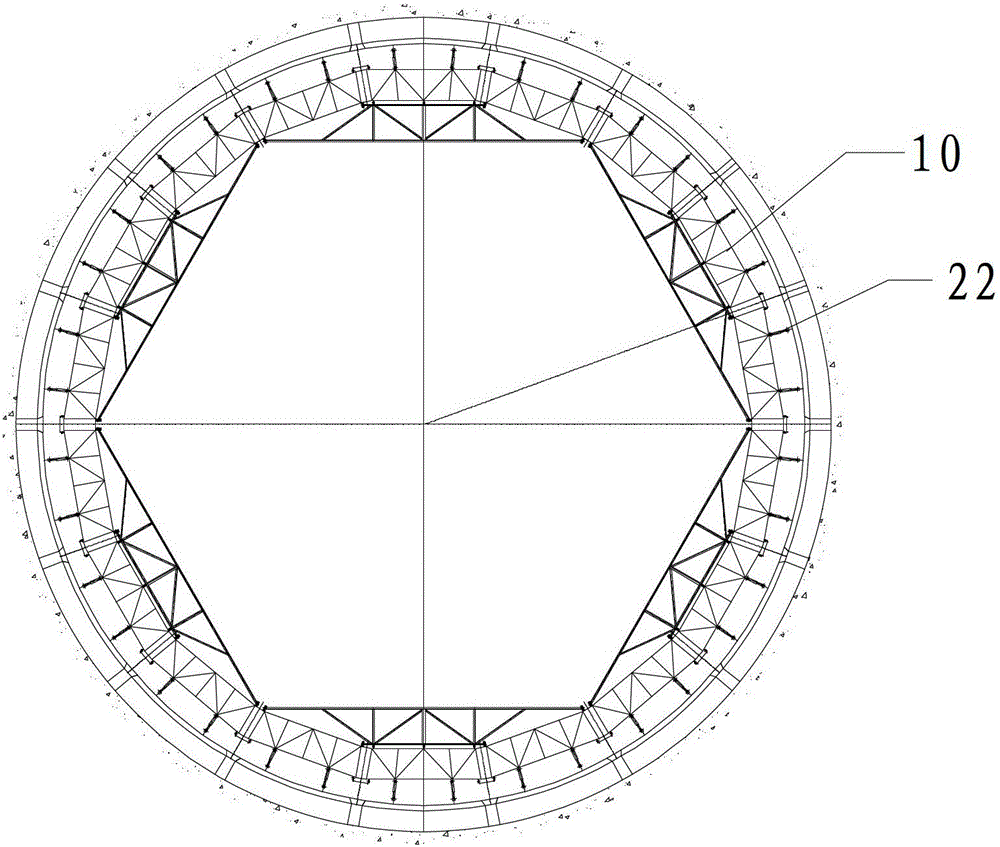

Full-circle integrated upside-down hanging formwork and its erecting and demoulding methods

A formwork and integrated technology, which is applied in earth-moving drilling, hydropower station, wellbore lining, etc., can solve the problems of not being able to seal the exposed and broken surrounding rock in time, greatly affecting the construction progress, and long construction cycle time, etc. Labor conditions, avoidance of direct interference, the effect of low equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The surge shaft of a certain power station is an open cylindrical differential type, with an excavation depth of 118m and an excavation diameter of 31m; the permanent structure concrete thickness is 2m, the diameter of the large well after lining is 27m, and the shaft depth is 108m. It is arranged in the middle of a thin ridge with steep terrain on both sides The upper part of about 60m is placed in the strong unloading Class V loose and broken surrounding rock. The surrounding rock lacks self-stability. After excavation, the rock mass around the upper shaft wall is thin and the well-forming conditions are very poor. Under such extremely poor geological conditions, to build a large-section open deep surge tank, the stability of the surrounding rock of the large shaft wall is the key to safe construction. In order to ensure the safety and progress of the construction, the parallel operation method of digging a large well, laying anchor rods and hanging net concrete, and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com