Production method and device for printing ink additive

A technology of ink additives and production methods, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as impossible overnight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

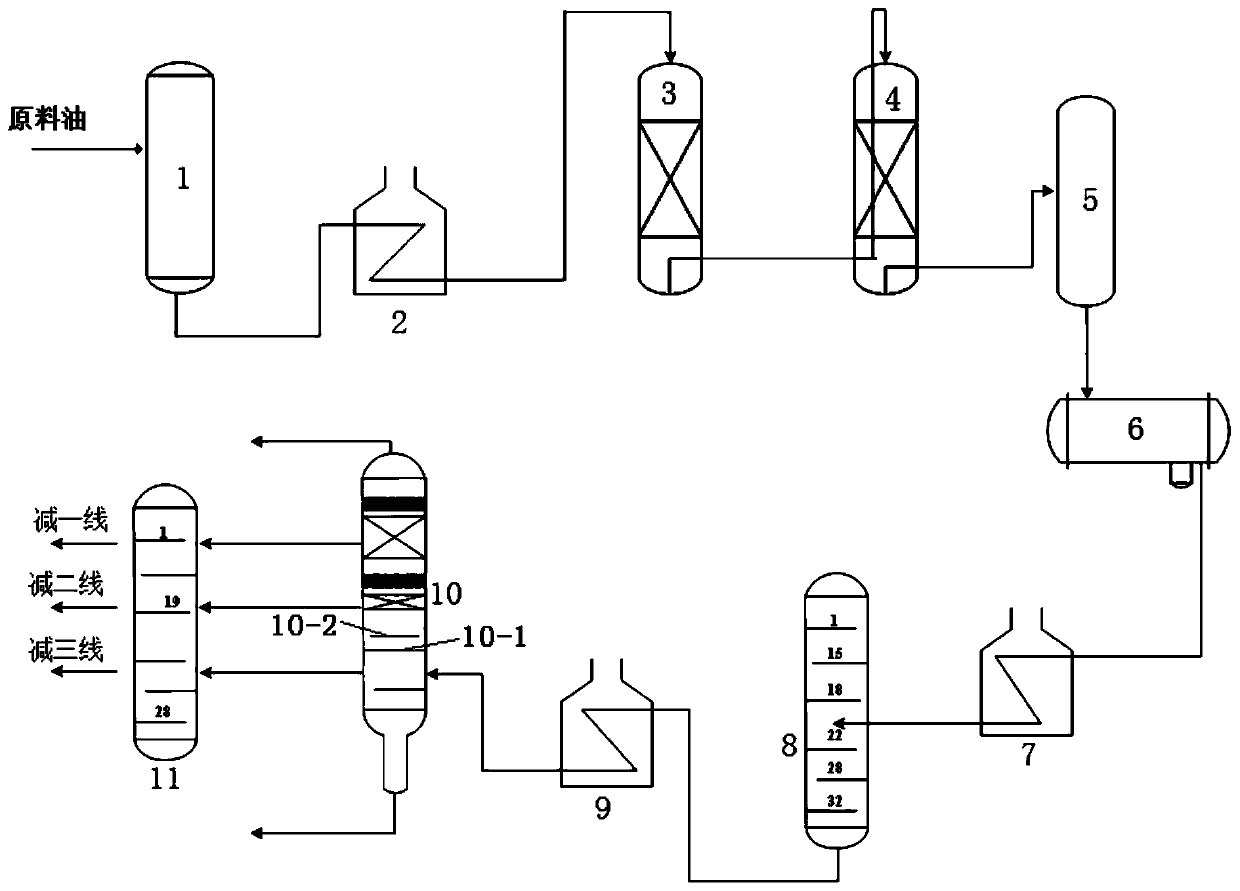

[0034] The invention provides a kind of production method of ink additive, comprises the following steps:

[0035] The light oil is subjected to hydroisomerization and hydrofining in sequence, and the refined product obtained is subjected to high-pressure gas-liquid separation and low-pressure gas-liquid separation to obtain low-fraction oil, and then the obtained low-fraction oil product is subjected to atmospheric pressure fractionation, reduction Pressure fractionation and stripping to obtain ink additives;

[0036] The temperature of the hydroisomerization is 330-340°C, and the temperature of the hydrofining is 240-250°C;

[0037] The pressure of the high-pressure gas-liquid separation is 14-15MPa;

[0038] The temperature of the atmospheric fractionation is 285-290°C, and the pressure of the atmospheric fractionation is 230-240KPa; the temperature of the vacuum fractionation is 350-360°C, and the pressure of the vacuum fractionation is 4-5KPa.

[0039] In the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com