Prefabricated anti-folding lightweight partition board

A light-weight partition board and assembly technology, which is applied in building materials, building components, buildings, etc., to achieve earthquake resistance, improve construction efficiency, and increase bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

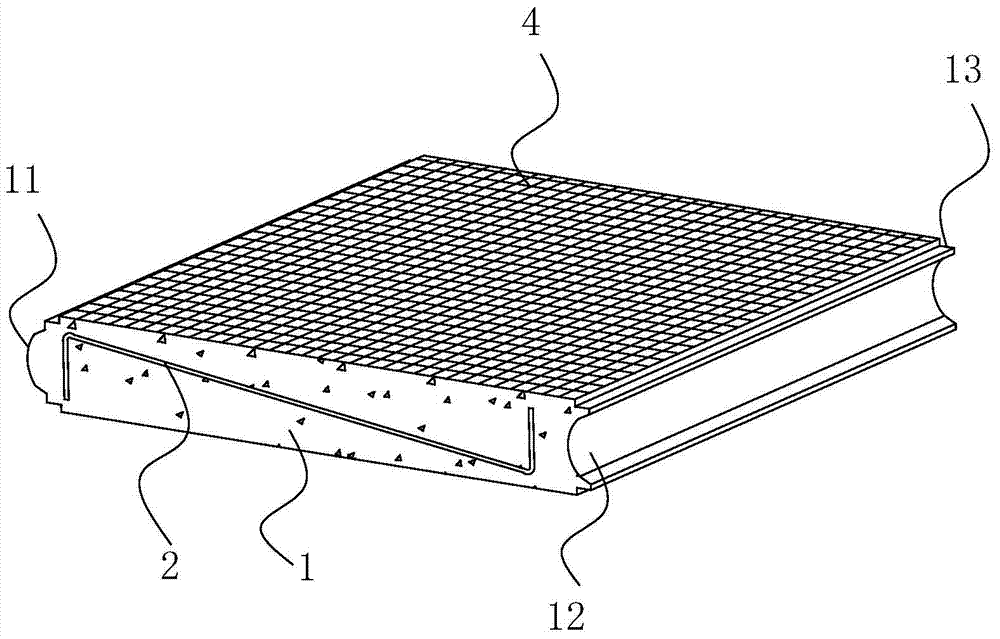

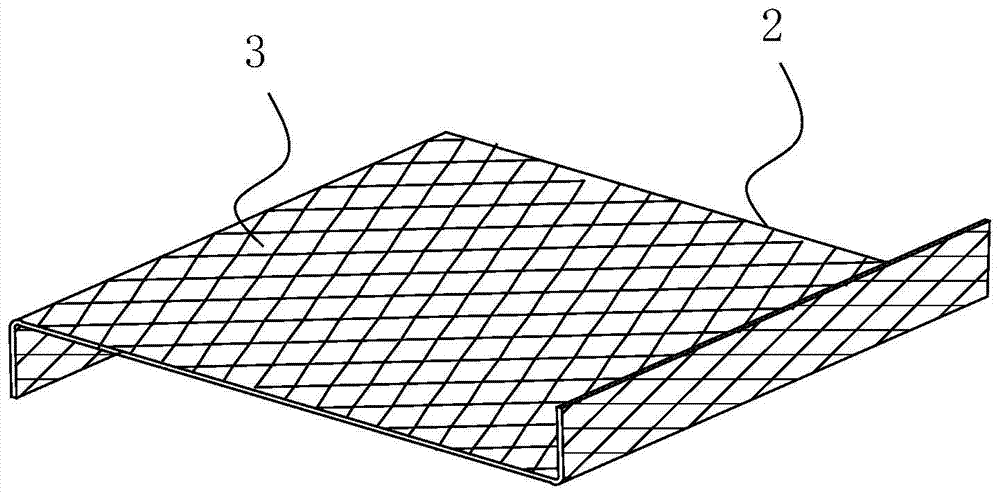

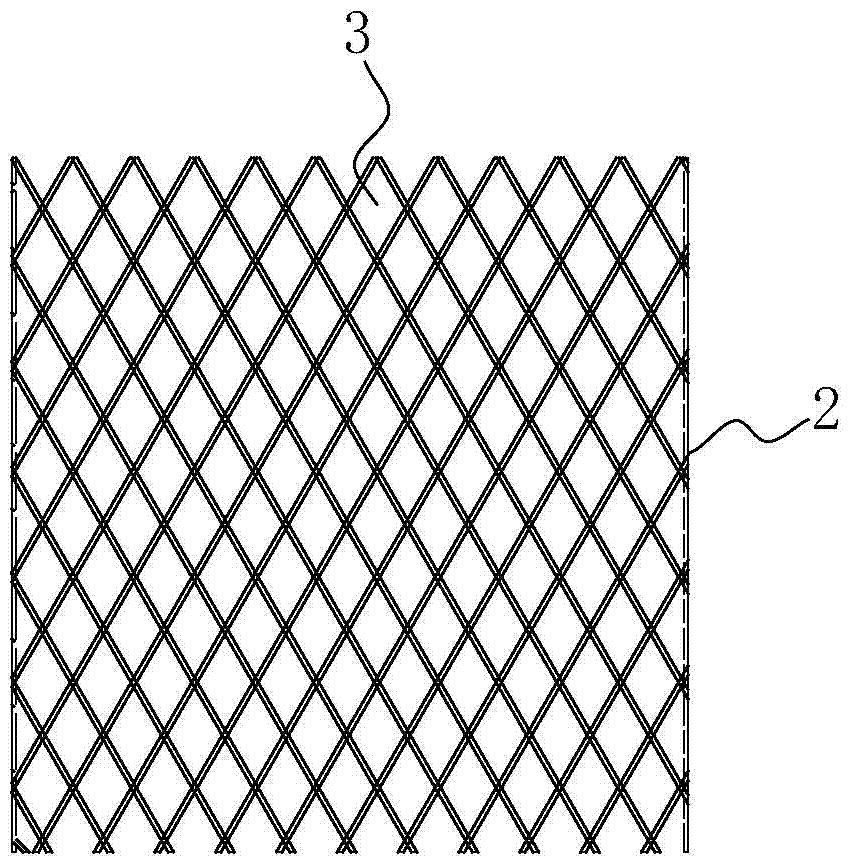

[0026] combine figure 1 , 2 As shown, the assembled anti-bending lightweight partition wall panel includes a panel body 1, a support net 3 is laid inside the panel body 1, and grids 2 are evenly distributed on the support net 3. The panel body 1 is formed by pouring concrete. The supporting net 3 is in the shape of a net as a whole, and is poured inside the plate body 1 . The aggregate of concrete is lightweight material, such as: polystyrene particles, lightweight ceramsite, etc. In this way, the overall weight of the partition board can be reduced, and the functions of light weight, heat preservation, heat insulation and sound insulation can be achieved. The support net 3 is formed by connecting wires, and the projection of the length direction of the wires on the board surface of the board body 1 is oblique. That is, the projection of the wire is neither parallel to the width direction of the board surface, nor parallel to the height or length direction of the board sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com