An Assembled Cavity Floor Slab for Forced Island

A cavity floor, prefabricated technology, applied in floors, buildings, building components, etc., can solve problems such as poor integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described below in conjunction with the accompanying drawings.

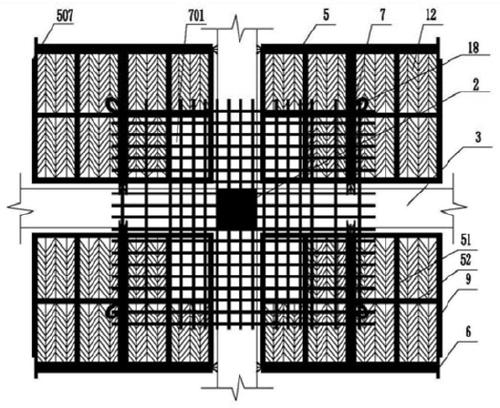

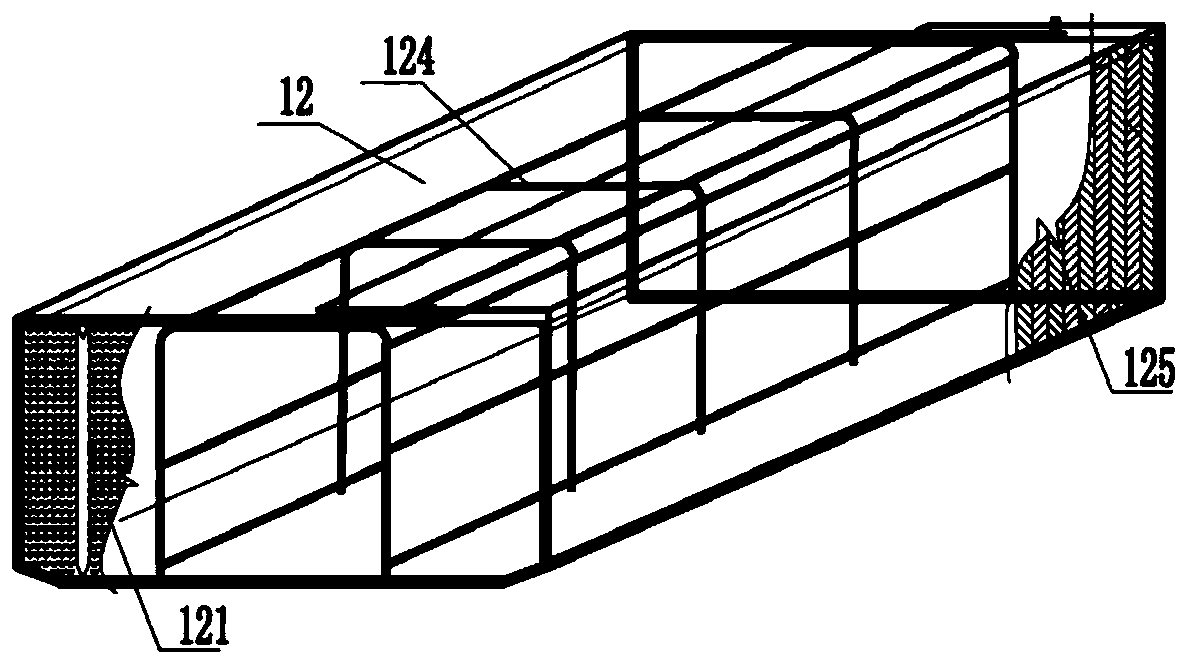

[0026] figure 1 It is a plan view of a prefabricated cavity floor of a force-bearing island of the present invention. When the present invention is implemented, a prefabricated cavity floor of a force-receiving island; the columns 2 constitute the column net of the floor; the main beam 3 and the columns 2 constitute the frame of the building, Columns and main beams are reinforced concrete structures or section steel structures; regenerative beams 6 are regenerated beams 6 produced by welding the rib beams 5 in the transverse direction of cavity plate members; cavity plate components are prefabricated in factories, including reinforced concrete rib beams 5 and exposed surfaces It is composed of steel bars, hole-forming components and lower flange plates; its geometric dimensions are determined according to the secondary design decomposition of architectural design drawings, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com