Nickel impact apparatus for nickel electroplating assembly line

An assembly line, electroplating nickel technology, applied in the direction of plating tank, electrolysis process, electrolysis components, etc., can solve the problems of overheating of liquid temperature, increase of cost of electroplating tank, affecting the quality of workpiece electroplating, etc., and achieve the effect of avoiding plating on the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

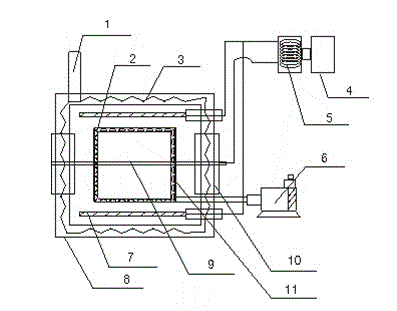

[0014] attached by figure 1 It can be seen that the present invention includes an electroplating tank body 8, and an anode 7 and a cathode 9 arranged in the electroplating tank body 8. The electroplating tank body 8 is a hollow interlayer, and a steam pipe 3 is arranged in the interlayer. The air agitation pipe 2 in the tank body 8 is connected with the air blower 6 . The above-mentioned anode 7 and cathode 9 are connected to the power supply 4 through the rectifier 5, and there are two anodes 7, which are respectively installed on both sides of the bottom of the electroplating tank body 8. The above-mentioned electroplating tank body 8 is also provided with a V-shaped groove 10 for fixing the cathode 9 .

[0015] The above-mentioned air stirring pipe 2 is provided with several holes 11, and the air stirring pipe 2 is connected with the air blower 6 to supply air thereto. A steam pipe 3 is installed in the interlayer on all sides of the electroplating tank body 8, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com