Salt-fog-resistant passivating agent special for galvanized steel sheet and preparation method of salt-fog-resistant passivating agent

A galvanized steel sheet, salt spray resistance technology, applied in the direction of metal material coating process, can solve the problems of poor salt spray resistance, insufficient corrosion resistance, etc., achieve good passivation performance, good salt spray resistance, Enhanced effect of salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

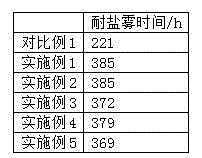

Examples

Embodiment 1

[0022] Special salt spray passivation agent for galvanized steel sheet, including the following components in parts by weight: 65 parts of silicon dioxide, 80 parts of barium metaborate, 108 parts of polyisobutylene succinimide, 83 parts of sodium hydrogen phosphate, hydroxyethylene 50 parts of base diphosphonic acid, 40 parts of glycerin, 50 parts of anionic surfactant, 60 parts of fatty acyldiethanolamine, 50 parts of additives, and 500 parts of water.

[0023] The anionic surfactant is polyacrylamide.

[0024] The auxiliary agent is glass cellulose.

[0025] The preparation method of the above special corrosion-resistant passivator for galvanized steel sheets comprises the following steps: adding water into the reaction kettle, and then sequentially adding silicon dioxide, barium metaborate, and polyisobutylene succinyl Imine, sodium hydrogen phosphate, anionic surfactant, fatty acyldiethanolamine, additives, heat up to 65°C, stir for 3 hours; add hydroxyethylene diphospho...

Embodiment 2

[0030] Salt spray passivation agent for galvanized steel sheets, including the following components in parts by weight: 50 parts of silicon dioxide, 60 parts of barium metaborate, 100 parts of polyisobutylene succinimide, 70 parts of sodium hydrogen phosphate, hydroxyethylene 30 parts of base diphosphonic acid, 20 parts of glycerol, 30 parts of anionic surfactant, 40 parts of fatty acyldiethanolamine, 30 parts of additives, and 300 parts of water.

[0031] The anionic surfactant is sodium succinate sulfonate.

[0032] The auxiliary agent is tetrafluoroethylene.

[0033] The preparation method of the above special corrosion-resistant passivator for galvanized steel sheets comprises the following steps: adding water into the reaction kettle, and then sequentially adding silicon dioxide, barium metaborate, and polyisobutylene succinyl Imine, sodium hydrogen phosphate, anionic surfactant, fatty acyldiethanolamine, additives, heat up to 60°C, stir for 2 hours; add hydroxyethylene ...

Embodiment 3

[0038] Special salt spray passivation agent for galvanized steel, including the following components in parts by weight: 80 parts of silicon dioxide, 100 parts of barium metaborate, 120 parts of polyisobutylene succinimide, 90 parts of sodium hydrogen phosphate, hydroxyethylene 80 parts of base diphosphonic acid, 70 parts of glycerol, 80 parts of anionic surfactant, 80 parts of fatty acyldiethanolamine, 100 parts of additives, and 1000 parts of water.

[0039] The anionic surfactant is sodium alkylbenzene sulfonate.

[0040] The auxiliary agent is tetrafluoroethylene.

[0041] The preparation method of the above special corrosion-resistant passivator for galvanized steel sheets comprises the following steps: adding water into the reaction kettle, and then sequentially adding silicon dioxide, barium metaborate, and polyisobutylene succinyl Imine, sodium hydrogen phosphate, anionic surfactant, fatty acyldiethanolamine, additives, heat up to 70°C, stir for 4 hours; add hydroxyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com