Atmospheric-pressure chemical vapor deposition coating reactor

A technology of atmospheric pressure chemical gas phase and reactor, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of limiting the scope of application of APCVD method and reducing the thermal efficiency of APCVD coating, and achieve novel design ideas, The effect of low cost and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

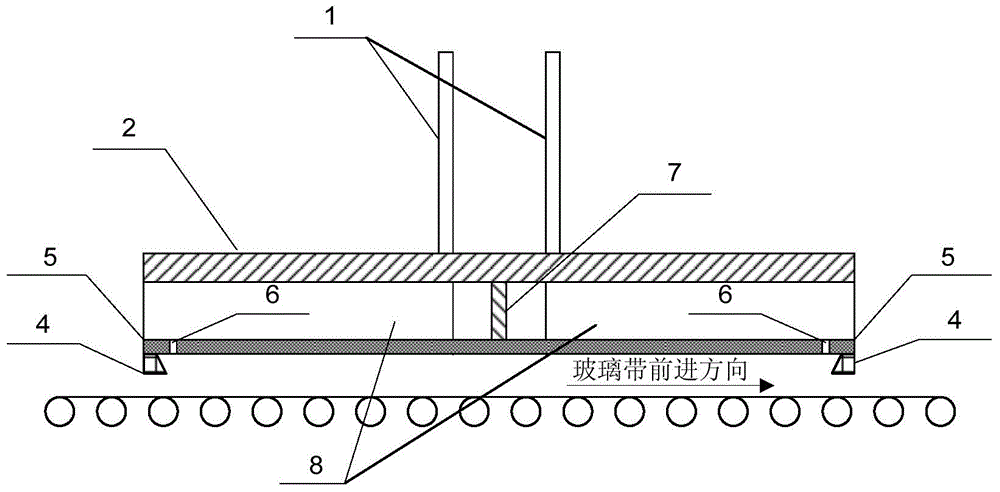

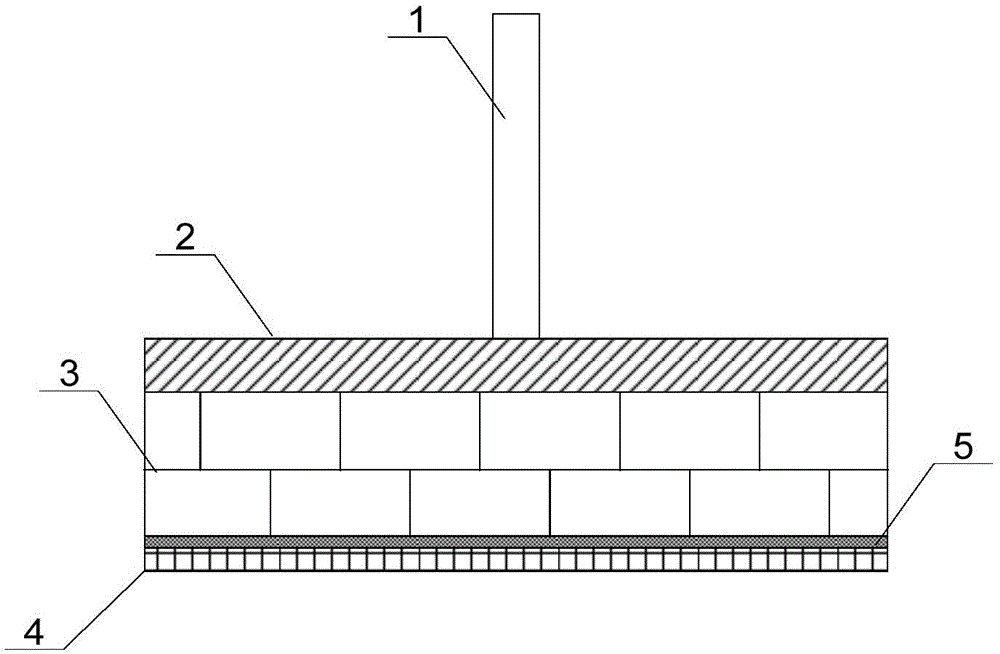

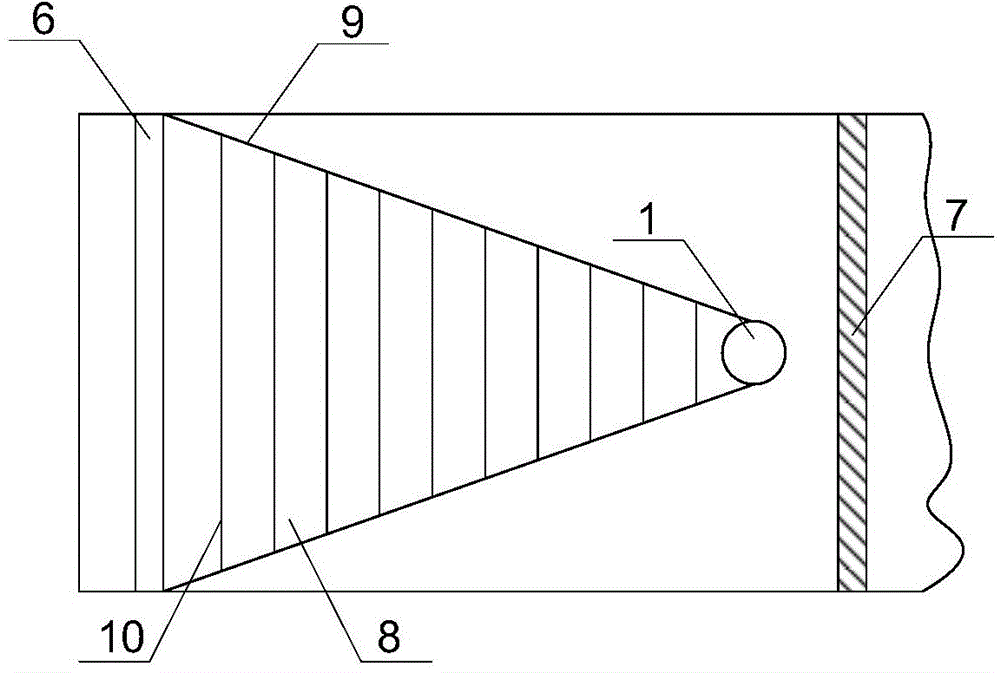

[0025] Such as figure 1 and figure 2 Shown, a kind of atmospheric pressure chemical vapor deposition coating reactor, comprises two rectangular parallelepiped air mixing chambers 8 as the main body of the reactor, the insulation layer 2 covered on the air mixing chamber 8, the slit 6 as the reactor coating nozzle, The elongated graphite stopper 4 at the exit of the slit, and the supporting air inlet pipe 1 and the reactor supporting and moving mechanism.

[0026] Two identical cuboid gas mixing chambers 8 are connected together with the gas mixing chamber partition 7 as a symmetrical mirror surface to form the main structure of the coating reactor, and are distributed upstream and downstream in the moving direction of the deposition substrate or glass ribbon. The two fully symmetrical gas mixing chambers 8 of the main structure of the coating reactor are connected by a partition 7 between the two gas mixing chambers 8 as a symmetrical mirror surface. When one of them is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com