A kind of preparation method of solid lubricating ZNS thin film

A solid lubrication and thin film technology, which is applied in gaseous chemical plating, metal material coating technology, coating, etc., can solve the problems of ZnS solid thin film without breakthrough, and achieve excellent mechanical properties, easy control of parameters, and uniform particle distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Put Si, which has been strictly cleaned on the surface, as the substrate, put it into the ALD deposition chamber, heat it to 150°C, and set diethylzinc Zn(C 2 h 5 ) 2 The pulse time of the source is 0.1 seconds, and the flushing time is 3 seconds; H 2 The pulse time of the S gas source was 10 seconds and the flush time was 15 seconds. In this implementation case, the number of deposition cycles is 300.

[0018] (2) The obtained ZnS thin film was exposed to 20% H 2 S and N 2 The vulcanization annealing was carried out under the mixed atmosphere, the temperature was 500°C, and the annealing time was 120 minutes.

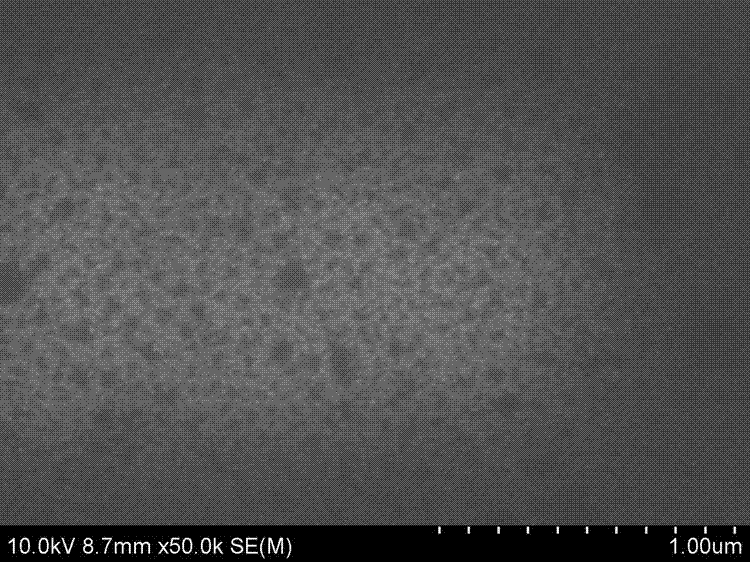

[0019] figure 1 This is the SEM image of ZnS obtained after sulfidation annealing; the grain distribution of the film is uniform after sulfidation annealing.

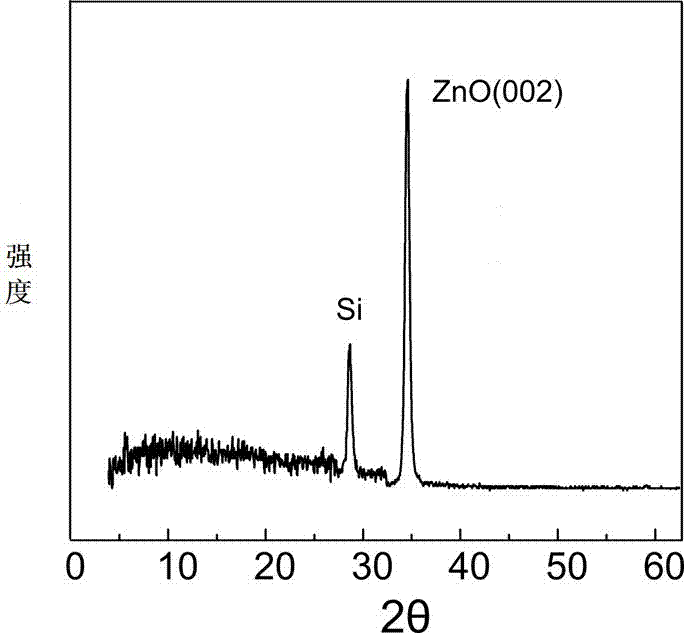

[0020] figure 2 Friction test graphs obtained for ZnS thin films after sulfurization annealing. The test conditions are: a steel ball with a diameter of 4mm under a load of 50g; reciprocatin...

Embodiment 2

[0022] (1) Put Si, which has been strictly cleaned on the surface, as the substrate, put it into the ALD deposition chamber, heat it to 120°C, set diethylzinc Zn(C 2 h 5 ) 2 The pulse time of the source is 0.2 s and the flush time is 8 s; H 2 The pulse time of the S gas source was 5 seconds and the flush time was 10 seconds. In this implementation case, the number of deposition cycles is 200.

[0023] (2) The obtained ZnS thin film was exposed to 30% H 2 S and N 2 The vulcanization annealing is carried out under the mixed atmosphere, the temperature is 500°C, and the annealing time is 90 minutes.

Embodiment 3

[0025] (1) Put Si, which has been strictly cleaned on the surface, as the substrate, put it into the ALD deposition chamber, heat it to 180°C, and set diethylzinc Zn(C 2 h 5 ) 2 The pulse time of the source is 0.3 s and the flush time is 8 s; H 2 The pulse time of the S gas source was 15 seconds and the flush time was 20 seconds. In this implementation case, the number of deposition cycles is 400.

[0026] (2) The obtained ZnS thin film was exposed to 40% H 2 S and N 2 The vulcanization annealing is carried out under the mixed atmosphere, the temperature is 500°C, and the annealing time is 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com