Two-stage curing vanadium extraction method of stone coal vanadium ores

A stone coal vanadium and aging technology, applied in the field of leaching, can solve the problems of insignificant strengthening effect, increase the burden of three wastes treatment, increase the difficulty of industrialization, etc., and achieve clean and environmental protection in the aging process, great industrial application prospects, and suppression of side reaction processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

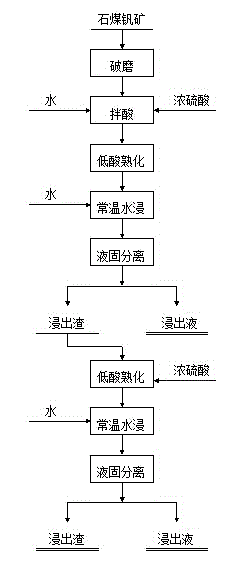

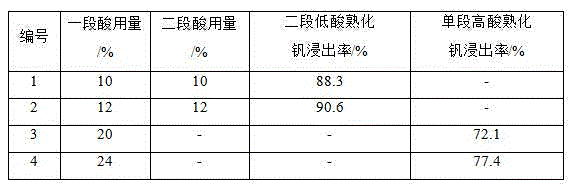

[0029] A method for extracting vanadium in the second-stage slaking of stone coal vanadium ore of the present invention, comprising the following steps: a stone coal vanadium mine in a certain place in the south, the main chemical components of the raw ore are C 12.25%, SiO 2 54.71%, Al 2 o 3 8.98%, V 2 o 5 0.72%, CaO 3.21%, using such as figure 1 The shown method of the present invention processes stone coal vanadium ore, first crushes and finely grinds the stone coal raw material to particle size<0.18mm, adds 10% water of the quality of stone coal vanadium ore and mixes well, then adds the quality of stone coal vanadium ore Mix well with 10% concentrated sulfuric acid, mature at 120°C for 4 hours, and then leaching with water with a liquid-solid ratio of 2:1 for 2 hours. 10% concentrated sulfuric acid with the quality of stone coal vanadium ore was mixed well, aged at 120°C for 4 hours, then leached with water with a liquid-solid ratio of 2:1 for 2 hours, and after li...

Embodiment 2

[0031] A method for extracting vanadium in the second-stage slaking of stone coal vanadium ore of the present invention, comprising the following steps: a stone coal vanadium mine in a certain place in the south, the main chemical components of the raw ore are C 12.25%, SiO 2 54.71%, Al 2 o 3 8.98%, V 2 o 5 0.72%, CaO 3.21%, using such as figure 1 The shown method of the present invention processes stone coal vanadium ore, first crushes and finely grinds the stone coal raw material to particle size<0.18mm, adds 10% water of the quality of stone coal vanadium ore and mixes well, then adds the quality of stone coal vanadium ore Mix well with 12% concentrated sulfuric acid, mature at 120°C for 4 hours, and then leaching with water with a liquid-solid ratio of 2:1 for 2 hours. After liquid-solid separation, obtain a vanadium-containing leaching solution and leaching residue, and then add 12% concentrated sulfuric acid with the quality of stone coal vanadium ore was mixed we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com