Benzoin oxime derivative and preparation method thereof

A technology of benzoin oxime and its derivatives, which is applied in the field of benzoin oxime derivatives and its preparation, can solve problems such as inconvenient use, threats to human body and environmental safety, etc., and achieve the effects of complex and diverse structures and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

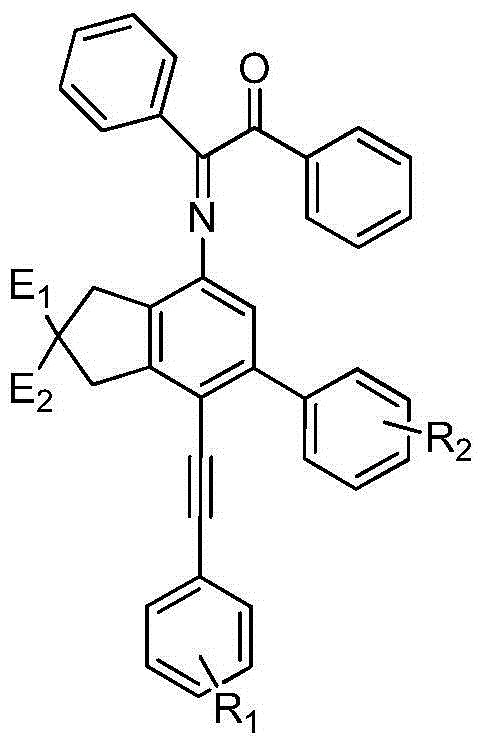

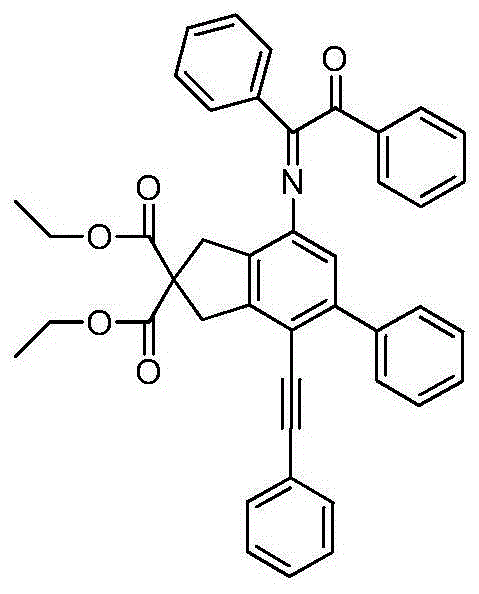

[0033] A benzoin oxime derivative, the structural formula is:

[0034]

[0035] A kind of preparation method of benzoin oxime derivative, described preparation method comprises the following steps:

[0036] a. Precursor synthesis;

[0037] b. Synthesis of the target product;

[0038] c. Purification.

[0039] Wherein, a, precursor synthesis, comprises the following steps:

[0040] (1) With 830mmol sodium hydride as a catalyst, 200mmol diethyl malonate and 440mmol propargyl bromide were added to 250mL anhydrous acetonitrile in an ice-water bath, stirred and reacted for 8 hours, the product was washed with water, extracted with ethyl acetate, and Press and spin dry, column chromatography (volume ratio ethyl acetate:petroleum ether=1:100) to obtain a white solid product, namely compound 1;

[0041] (2) Mix 80mmol of compound 1 with 200mmol of phenylethynyl bromide in 1.3g of Pd (PPh 3 ) 2 Cl 2 / CuI anhydrous and oxygen-free catalytic system, Pd(PPh 3 ) 2 Cl 2 The mol...

Embodiment 2

[0053] A benzoin oxime derivative, the structural formula is:

[0054]

[0055] A kind of preparation method of benzoin oxime derivative, described preparation method comprises the following steps:

[0056] a. Precursor synthesis;

[0057] b. Synthesis of the target product;

[0058] c. Purification.

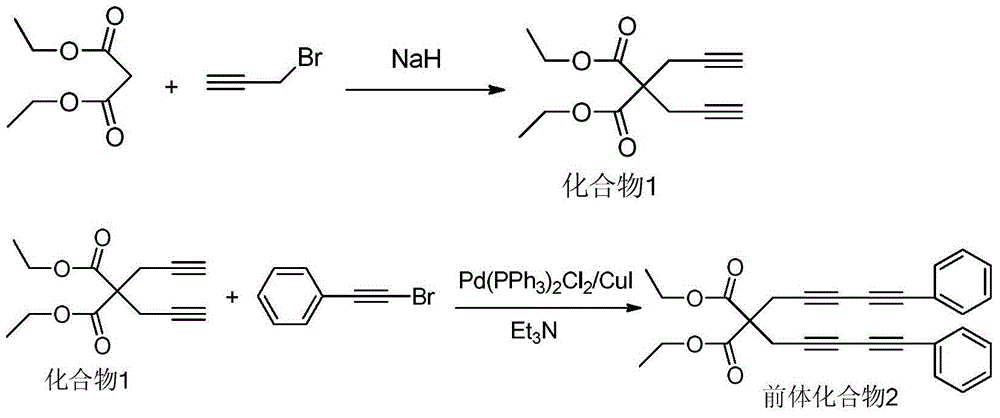

[0059] Wherein, a, precursor synthesis, comprises the following steps:

[0060] (1) With 800mmol sodium hydride as a catalyst, 200mmol diisopropyl malonate and 500mmol propargyl bromide were added to 200ml anhydrous acetonitrile in an ice-water bath, stirred and reacted for 10 hours, the product was washed with water, extracted with ethyl acetate, Spinning to dryness under reduced pressure, column chromatography (volume ratio of ethyl acetate:petroleum ether=1:100) gave a white solid product, namely compound 3;

[0061] (2) Mix 80mmol compound 1 with 200mmol p-methylphenylethynyl bromide in 2.17gPd(PPh 3 ) 2 Cl 2 / CuI anhydrous and oxygen-free catalytic system, Pd(PPh 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com