Method for by-producing steam in ortho-nitrotoluene separation process

A technology for the separation process of o-nitrotoluene, which is applied in the field of by-product steam in the separation process of o-nitrotoluene, which can solve the problems of unfavorable environmental protection and easy emission of irritating odor, and achieve pollution reduction, cost reduction, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

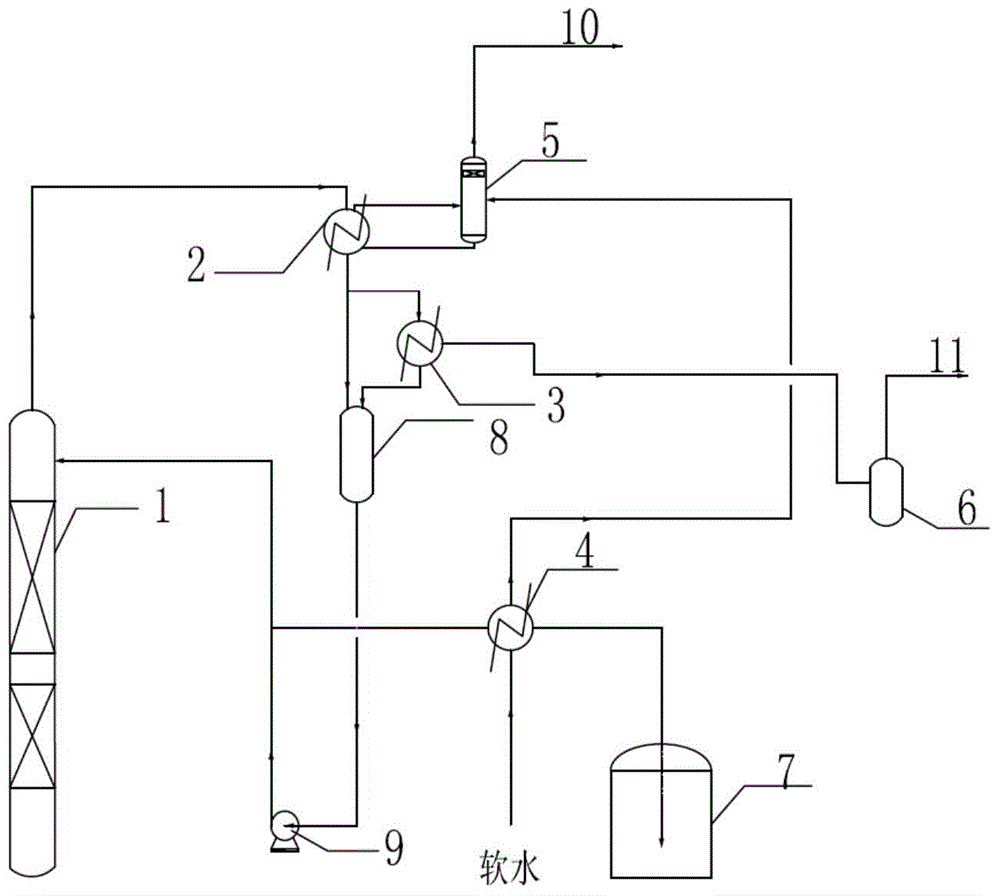

[0022] as attached figure 1 As shown, the device used in the inventive method comprises an ortho rectification tower 1; condenser 2; recooler 3; soft water preheater 4; steam drum 5; vacuum buffer tank 6; product storage tank 7; Return pump 9; steam pipe network 10; vacuum gas collection system 11.

[0023] The material after the separation of para-nitrotoluene mainly contains o-nitrotoluene and m-nitrotoluene, with a flow rate of 2000kg / h and a temperature of 125°C, it enters the ortho-position rectification tower 1 for rectification, and after rectification, the ortho-nitrotoluene The gas phase of the toluene product enters the condenser 2 from the top of the rectifying tower 1, and is used as a heat medium to cool down and condense. The uncooled product gas phase enters the recooler 3 for further cooling, and the cooled product is condensed together with the condenser 2 The product that comes down enters the reflux tank 8; the uncondensed trace gas phase in the recooler 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com