Biological fermentation organic fertilizer and preparation method thereof

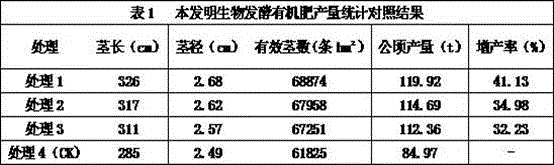

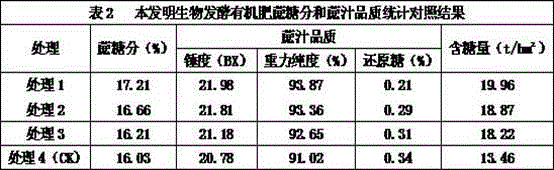

A bio-fermentation and organic fertilizer technology is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers. It can solve the problems of reduced fertilization benefits, environmental pollution, soil fertility, and agricultural product quality degradation, and achieves agricultural product quality improvement. Improve the quality of sucrose and cane juice, and promote the effect of thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: (1) Take 8 kilograms of potassium alginate, 15 kilograms of 400 mesh medical stone powder, 1.2 kilograms of Bacillus stearothermophilus, and 1.2 kilograms of Thermomonas brown, add 40 kilograms of water and stir well;

[0020] (2) Take 25 kilograms of peanut shells, 32 kilograms of potato starch residue, and 28 kilograms of castor cake; add 60 kilograms of water and heat to 85~95℃ and stir evenly, keep for 3~4 hours; then control the temperature to 48~58℃, Add the mixture in step (1) and react for 25-30 days;

[0021] (3) Take 0.9 kg of Lactobacillus plantarum, 1.8 kg of Jingyang Streptomyces, 1.2 kg of Trichoderma viride, 1.4 kg of Alcaligenes faecalis, 20 kg of 400-mesh medical stone powder, add 30 kg of water, and mix well;

[0022] (4) Take 110 kilograms of deer manure, 40 kilograms of goose manure, and 13 kilograms of ammonium bicarbonate, and add them to the mixture in step (2) to react for 3 to 5 days, then control the temperature to 29-38°C, add step (3) ),...

Embodiment 2

[0024] Example 2: (1) Take 8 kilograms of potassium alginate, 14 kilograms of 400 mesh medical stone powder, 1 kilogram of Bacillus stearothermophilus, and 1 kilogram of Thermomonas brown, add 40 kilograms of water and mix well;

[0025] (2) Take 22 kilograms of peanut shells, 30 kilograms of potato starch residue, and 25 kilograms of castor cake; add 60 kilograms of water and heat to 85~95℃ and stir evenly, keep for 3~4 hours; then control the temperature to 48~58℃, Add the mixture in step (1) and react for 25-30 days;

[0026] (3) Take 0.8 kg of Lactobacillus plantarum, 1.5 kg of Jingyang Streptomyces, 1.2 kg of Trichoderma viride, 1.2 kg of Alcaligenes faecalis, 19 kg of 400-mesh medical stone powder, add 30 kg of water, and mix well;

[0027] (4) Take 105 kilograms of deer manure, 38 kilograms of goose manure, and 12 kilograms of ammonium bicarbonate, add them to the mixture in step (2) and react for 3 to 5 days, then control the temperature to 29-38°C, add step (3) ), react for...

Embodiment 3

[0029] Example 3: (1) Take 9 kg of potassium alginate, 16 kg of 400 mesh medical stone powder, 1.5 kg of Bacillus stearothermophilus, and 1.5 kg of Thermomonas brown, add 40 kg of water, and mix well;

[0030] (2) Take 26 kilograms of peanut shells, 35 kilograms of potato starch residue, and 30 kilograms of castor cake; add 60 kilograms of water and heat to 85~95℃, stir evenly, keep for 3~4 hours; then control the temperature to 48~58℃, Add the mixture in step (1) and react for 25-30 days;

[0031] (3) Take 1.2 kg of Lactobacillus plantarum, 2 kg of Jingyang Streptomyces, 1.5 kg of Trichoderma viride, 1.5 kg of Alcaligenes faecalis, 22 kg of 400-mesh medical stone powder, add 30 kg of water, and mix well;

[0032] (4) Take 120 kilograms of deer manure, 44 kilograms of goose manure, and 15 kilograms of ammonium bicarbonate, and add them to the mixture in step (2) to react for 3 to 5 days, then control the temperature to 29 to 38°C, and add step (3) ), react for 25-30 days;

[0033] (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com