Pretreatment system and pretreatment method based on dissolved oxygen control in sewage treatment plant

A technology for sewage treatment plants and dissolved oxygen control, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as direct or indirect consumption of influent carbon sources , to achieve significant energy saving and consumption reduction effects, strong operability, and simple engineering design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

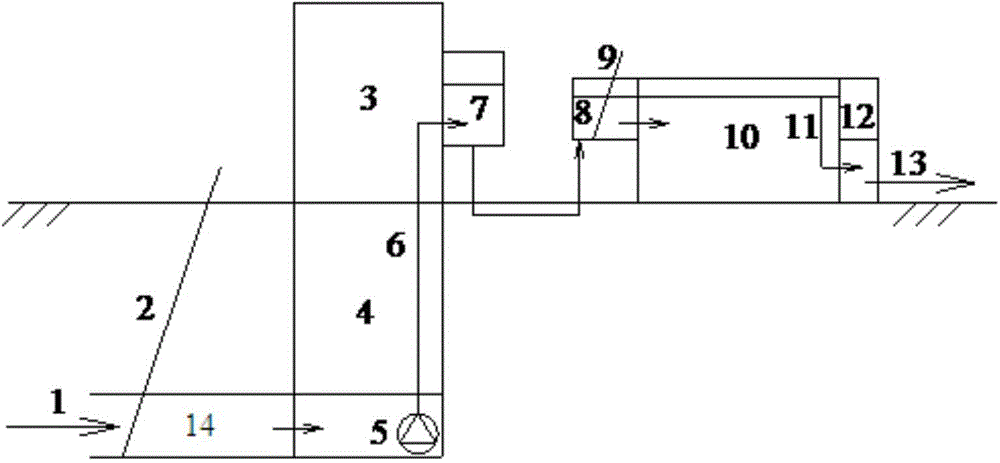

[0037] Embodiment one: a kind of sewage treatment plant pretreatment method based on dissolved oxygen control, comprises the following steps:

[0038] a. The sewage treatment plant intake water 1 from the urban drainage pipe network enters the sump 4 below the intake pump house 3 after removing relatively large floating objects through the coarse grid 2 with a grid distance of 25mm in the sewage intake channel 14;

[0039] b. Under the action of the submersible lift pump 5, the sewage in the sump 4 enters the lift pump outlet channel 7 through the lift pump outlet pipe 6 in a submerged outflow manner;

[0040] c. The sewage in the outlet channel 7 of the lifting pump enters the front end of the inlet channel 8 of the aeration grit chamber through the pipeline by gravity flow, and removes fine particles through the fine grid 9 with an aperture of 3 mm in the inlet channel 8 of the aeration grit chamber Gravity enters the aeration grit chamber 10 after being wrapped with objects...

Embodiment 2

[0044] Embodiment two: a kind of sewage treatment plant pretreatment method based on dissolved oxygen control, comprises the following steps:

[0045] a. The sewage treatment plant intake water 1 from the urban drainage pipe network enters the sump 4 below the intake pump house 3 after removing relatively large floating objects through the coarse grid 2 with a grid distance of 20 mm in the sewage intake channel 14;

[0046] b. Under the action of the submersible lift pump 5, the sewage in the sump 4 enters the lift pump outlet channel 7 through the lift pump outlet pipe 6 in a submerged outflow manner;

[0047] c. The sewage in the outlet channel 7 of the lifting pump enters the front end of the inlet channel 8 of the aeration grit chamber through the pipeline by gravity flow, and removes fine particles through the fine grid 9 with an aperture of 2 mm in the inlet channel 8 of the aeration grit chamber Gravity enters the aeration grit chamber 10 after being wrapped with objects;...

Embodiment 3

[0051] Embodiment three: a kind of sewage treatment plant pretreatment method based on dissolved oxygen control, comprises the following steps:

[0052] a. The sewage treatment plant intake water 1 from the urban drainage pipe network enters the sump 4 below the intake pump house 3 after removing relatively large floating objects through the coarse grid 2 with a grid distance of 20 mm in the sewage intake channel 14;

[0053] b. Under the action of the submersible lift pump 5, the sewage in the sump 4 enters the lift pump outlet channel 7 through the lift pump outlet pipe 6 in a submerged outflow manner;

[0054] c. The sewage in the outlet channel 7 of the lifting pump enters the front end of the inlet channel 8 of the aeration grit chamber through the pipeline by gravity flow, and removes fine particles through the fine grid 9 with an aperture of 1mm in the inlet channel 8 of the aeration grit chamber Gravity enters the aeration grit chamber 10 after being wrapped with objec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com