Wear-resistant high-transmittance reflecting piece

A reflective sheet, high-transparency technology, applied in the optical field, can solve the problem of low reflectivity of the reflective sheet, and achieve the effects of increasing light transmittance, improving reflectivity, and preventing lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

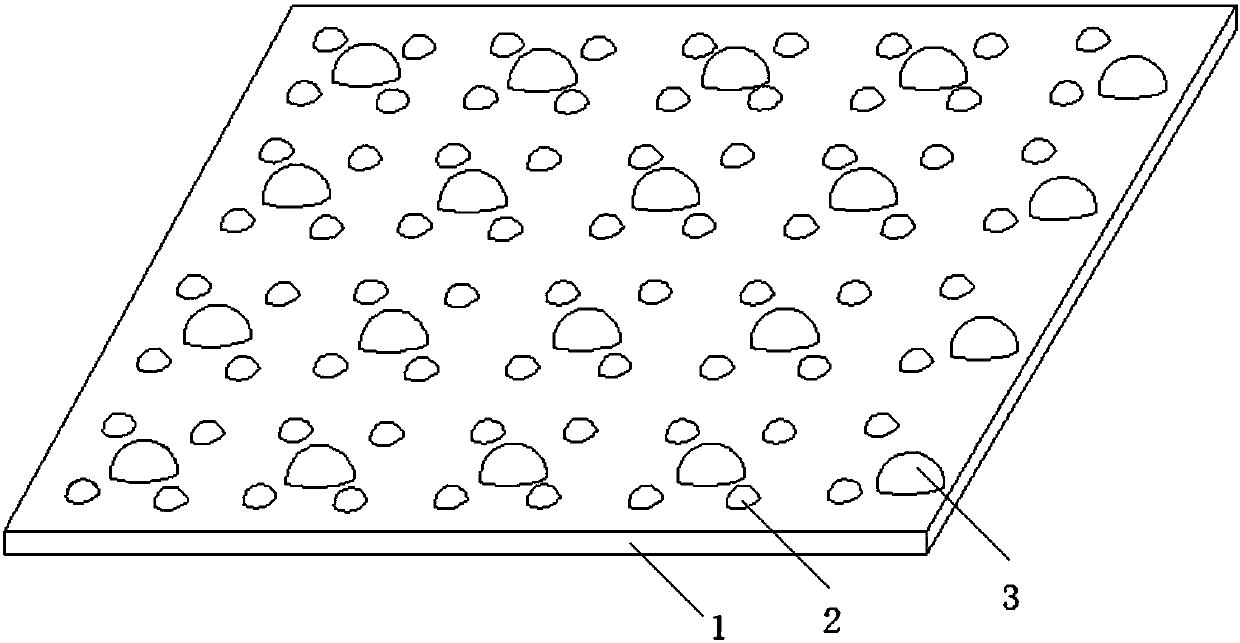

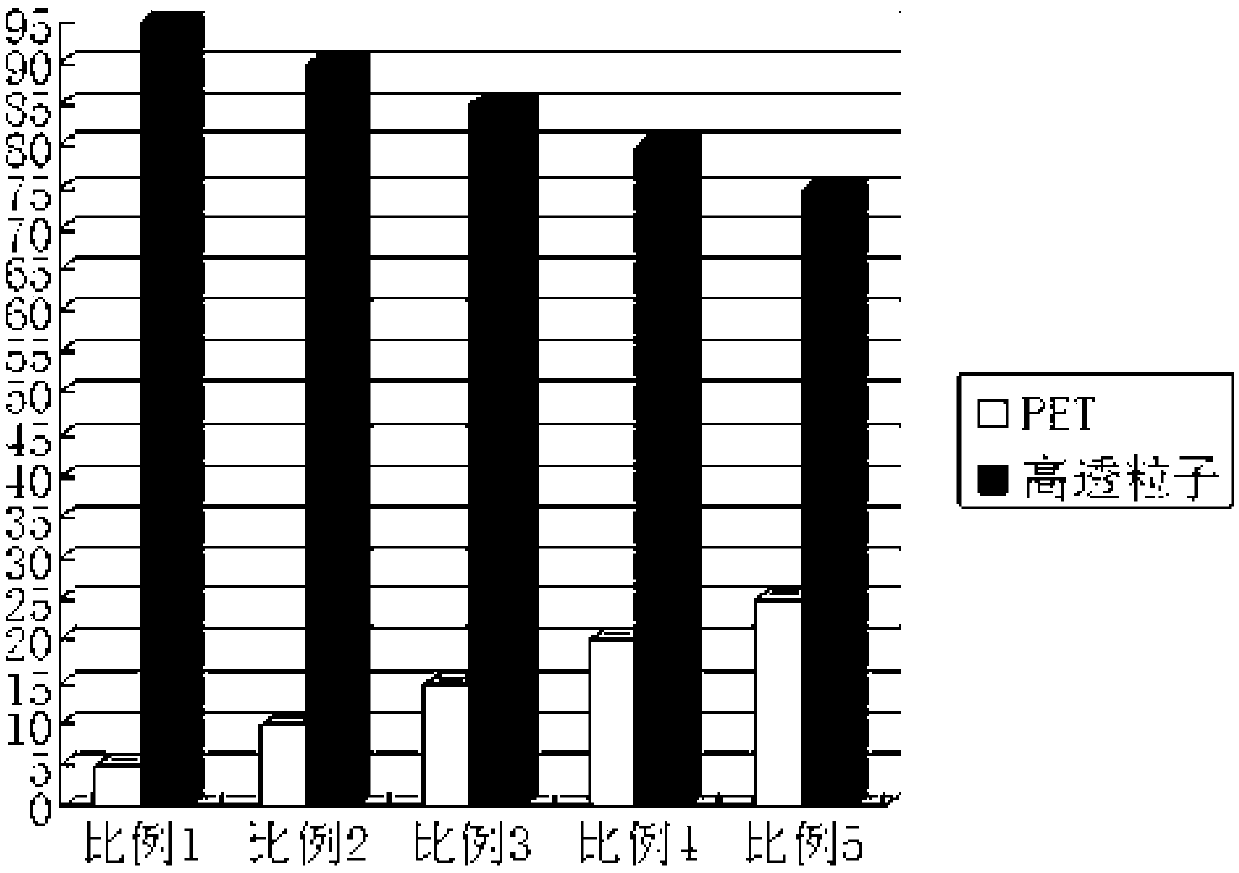

[0013] Referring to the accompanying drawings, a wear-resistant high-transmittance reflective sheet includes a PET substrate 1, a plurality of high-transmission particles 2 and PET particles 3 are distributed on the surface of the PET substrate 1, and the particle diameter of the PET particles 3 is larger than that of the high-transmission particles 2. , the quantity of highly transparent particles 2 is more than that of PET particles 3; the surface of PET substrate 1 is evenly coated with a plurality of highly transparent particles 2, the particle diameter of highly transparent particles 2 is 5 μm, and the surface of PET substrate 1 is evenly coated There are PET particles 3, and the particle size of the PET particles 3 is 15 μm; the highly transparent particles 2 occupy 80% of the surface area of the PET substrate 1, and the highly transparent particles 2 occupy 20% of the surface area of the PET substrate 1.

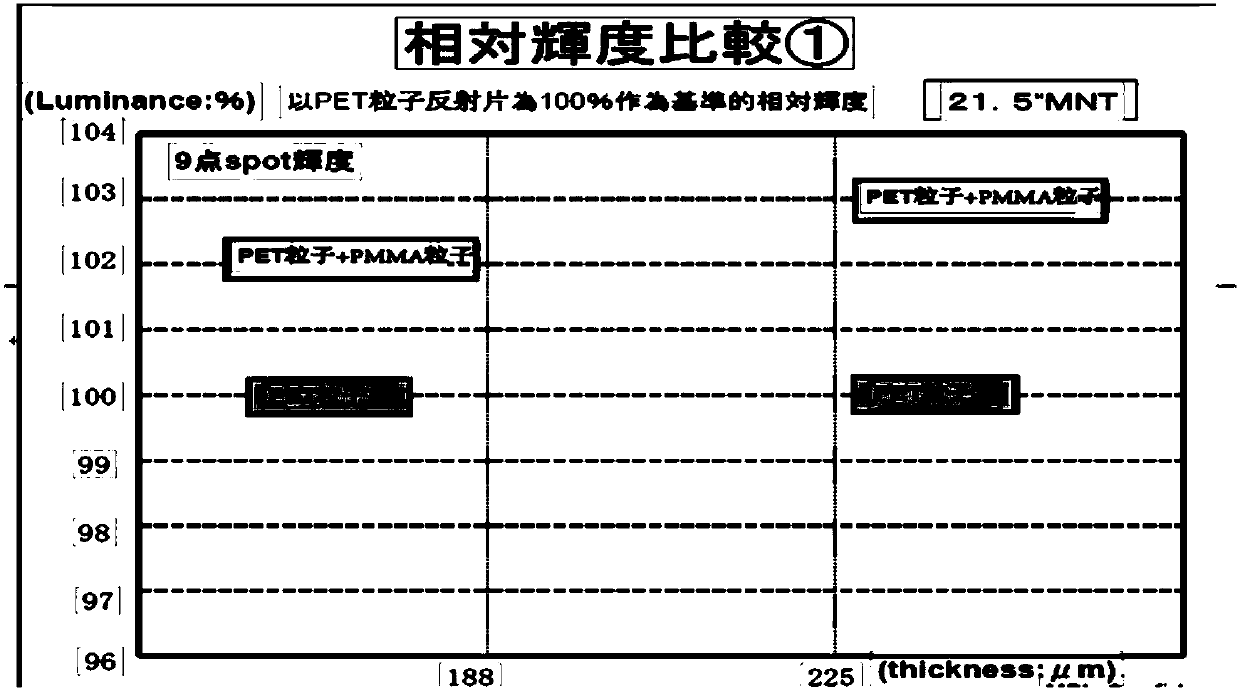

[0014] Verification and confirmation of different coating rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com