Method for preparing selenium

A selenium solution and leaching technology, applied in the field of selenium production, can solve the problems of lack of effective and reasonable recovery, no special treatment, waste of resources, etc., and achieve high selenium leaching rate, improve recycling rate, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

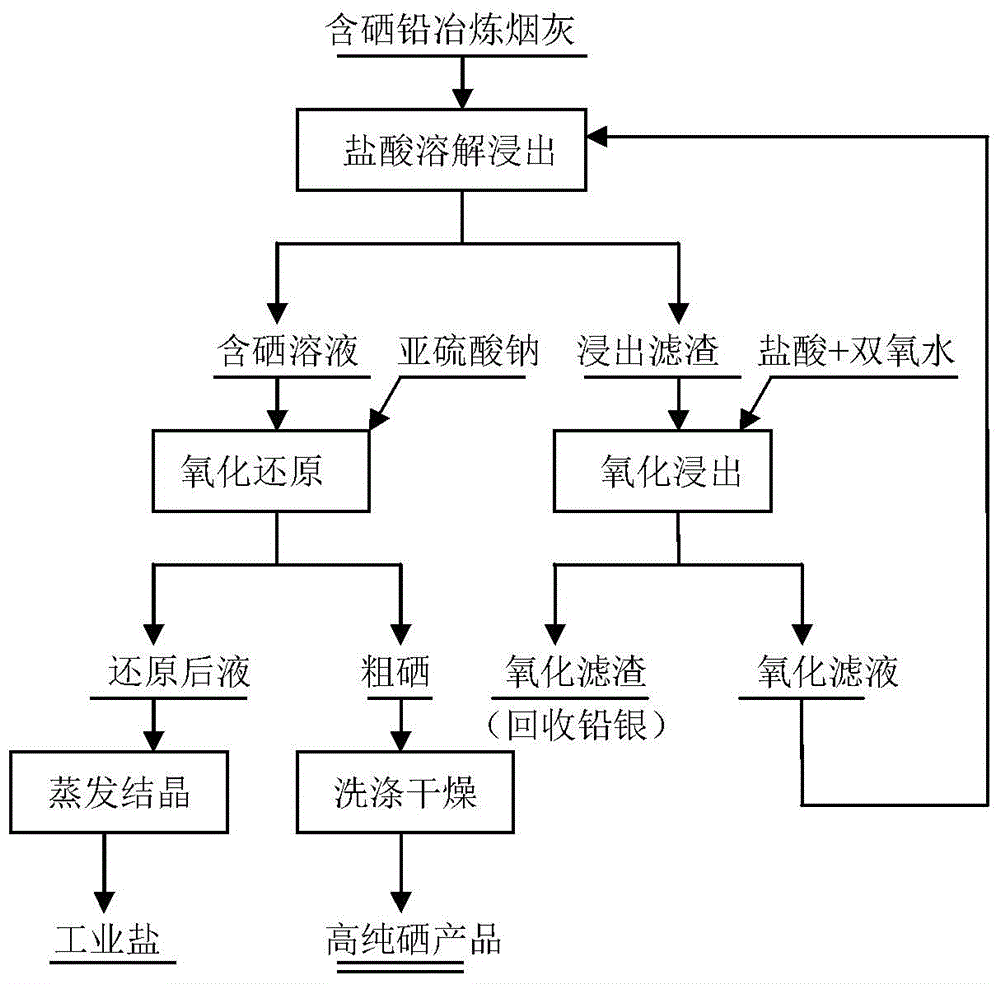

[0023] see figure 1 , which is a process flow chart for preparing selenium in an embodiment of the present invention. As an embodiment of the present invention, the method for preparing selenium includes the following steps.

[0024] (1), take by weighing 500g dry selenium-containing lead smelting flue dust, adopt hydrochloric acid to dissolve and leach this selenium-containing lead smelting flue dust, the liquid-solid ratio of hydrochloric acid and selenium-containing lead smelting flue dust is 3:1g / g, the pH value of hydrochloric acid solution 4 to 5. Wherein, the selenium-containing lead smelting dust contains selenium (Se): 6.12%, silver (Ag): 4.86%, lead (Pb): 36.91% (by mass fraction). In this embodiment, the controlled dissolution and leaching temperature is 50° C., and the leaching time is 1.5 hours. Preferably, the hydrochloric acid solution is stirred at a constant speed during the dissolution and leaching process, and the stirring speed may be 60 r / min. In this ...

Embodiment 2

[0034] see figure 1 , which is a process flow chart for preparing selenium in an embodiment of the present invention. As an embodiment of the present invention, the method for preparing selenium includes the following steps.

[0035] (1), take by weighing 1000g dry selenium-containing lead smelting dust, adopt hydrochloric acid to dissolve and leach this selenium-containing lead smelting dust, the liquid-solid ratio of hydrochloric acid and selenium-containing lead smelting dust is 4:1g / g, the pH value of hydrochloric acid solution 5 to 6. Wherein, the selenium-containing lead smelting dust contains selenium (Se): 5.83%, silver (Ag): 5.17%, lead (Pb): 38.34% (by mass fraction). In this embodiment, the controlled dissolution and leaching temperature is 60° C., and the leaching time is 2 hours. Preferably, the hydrochloric acid solution is stirred at a constant speed during the dissolution and leaching process, and the stirring speed may be 50 r / min. In this step, selenium o...

Embodiment 3

[0045] see figure 1 , which is a process flow chart for preparing selenium in an embodiment of the present invention. As an embodiment of the present invention, the method for preparing selenium includes the following steps.

[0046] (1), take by weighing 800g dry selenium-containing lead smelting flue dust, adopt hydrochloric acid to dissolve and leach this selenium-containing lead smelting flue dust, the liquid-solid ratio of hydrochloric acid and selenium-containing lead smelting flue dust is 3.5:1g / g, the pH value of hydrochloric acid solution 4 to 5. Wherein, the selenium-containing lead smelting dust contains selenium (Se): 6.08%, silver (Ag): 5.56%, lead (Pb): 37.47% (by mass fraction). In this embodiment, the controlled dissolution and leaching temperature is 58° C., and the leaching time is 1.5 hours. Preferably, the hydrochloric acid solution is stirred at a constant speed during the dissolution and leaching process, and the stirring speed may be 75 r / min. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com