In-mould injection moulding process of aluminum shell

An in-mold injection molding and molding technology, applied in the coating and other directions, can solve the problems of easy separation, difficult joining, and difficult CNC processing, and achieve the effect of firm bonding, simple process, and difficult separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The in-mold injection molding process of the aluminum casing of the present embodiment comprises the following steps:

[0049] The first step, cleaning the aluminum case:

[0050] Clean the surface of the aluminum casing;

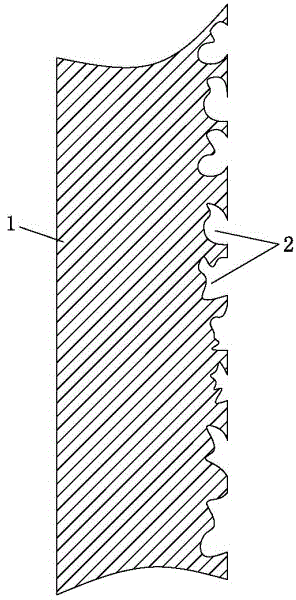

[0051] In the second step, the surface of the aluminum casing is treated with nano-scale microporous surface:

[0052] Step 1, fix the aluminum casing with a clean surface on the rack with electrodes;

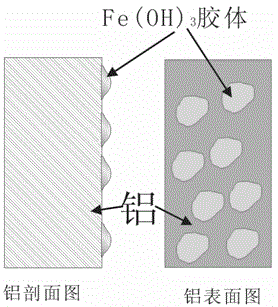

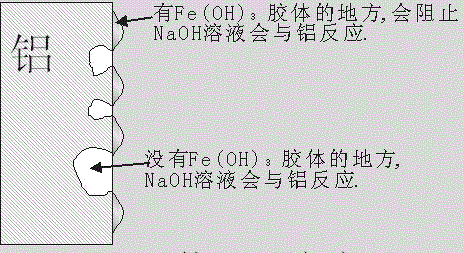

[0053] Step 2, use the hanger to put the aluminum casing into the Fe(OH) 3 In the colloidal solution, electrify and carry out electrolytic treatment for 20 seconds; wherein, Fe(OH) 3 The colloidal solution is obtained by adding FeCl 3 Fe(OH) generated by reaction with hot water in a heating tank 3 Colloid saturated solution.

[0054] Step 3, put the aluminum casing after the electrolytic treatment in step 2 into a NaOH solution with a concentration of 4% and soak for 30 seconds;

[0055] Step 4, take the aluminum casing out of the NaOH solu...

Embodiment 2

[0064] The in-mold injection molding process of the aluminum casing of the present embodiment comprises the following steps:

[0065] The first step, cleaning the aluminum case:

[0066] Clean the surface of the aluminum casing;

[0067] In the second step, the surface of the aluminum casing is treated with nano-scale microporous surface:

[0068] Step 1, fix the aluminum casing with a clean surface on the rack with electrodes;

[0069] Step 2, use the hanger to put the aluminum casing into the Fe(OH) 3 In the colloidal solution, energize and carry out electrolytic treatment for 30 seconds; wherein, Fe(OH) 3 The colloidal solution is obtained by adding FeCl 3 Fe(OH) generated by reaction with hot water in a heating tank 3 Colloid saturated solution.

[0070] Step 3, put the aluminum casing after the electrolytic treatment in step 2 into an 8% NaOH solution and soak for 20 seconds;

[0071] Step 4, take the aluminum casing out of the NaOH solution and put it in 10% N...

Embodiment 3

[0080] The in-mold injection molding process of the aluminum casing of the present embodiment comprises the following steps:

[0081] The first step, cleaning the aluminum case:

[0082] Clean the surface of the aluminum casing;

[0083] In the second step, the surface of the aluminum casing is treated with nano-scale microporous surface:

[0084] Step 1, fix the aluminum casing with a clean surface on the rack with electrodes;

[0085] Step 2, use the hanger to put the aluminum casing into the Fe(OH) 3 In the colloidal solution, electrify and carry out electrolytic treatment for 10 seconds; wherein, Fe(OH) 3 The colloidal solution is obtained by adding FeCl 3 Fe(OH) generated by reaction with hot water in a heating tank 3 Colloid saturated solution.

[0086] Step 3, put the aluminum casing after the electrolytic treatment in step 2 into a NaOH solution with a concentration of 2% and soak for 40 seconds;

[0087] Step 4, take the aluminum casing out of the NaOH solu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap