Method for drying dipped cord fabric based on ultraviolet light and high-energy electrons

A technology of impregnated cord fabric and high-energy electronics, which is applied in the field of tire manufacturing, can solve the problems of low solid content of impregnated glue, high energy consumption, and VOC emissions, and achieve the goals of cost control and maintenance, easy cost and maintenance, and improvement of production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

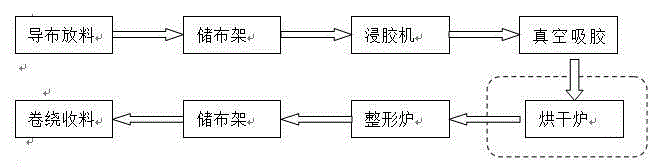

[0024] refer to figure 1 , this embodiment is a technical process for curing and drying dipped cord fabrics in a heat-drying manner, which belongs to the prior art, and includes sequentially guiding the cloth to discharge to the cloth storage rack, then entering the dipping machine for dipping, and then vacuum suction Recover the excess impregnated glue, then dry it through the drying oven, then enter the shaping oven for shaping, and finally wind up the material on the cloth storage rack.

Embodiment 2

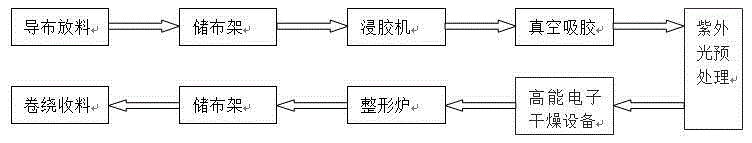

[0026] refer to figure 2 , this embodiment is the process flow of the method of drying dipped cord fabrics based on ultraviolet light and high-energy electrons of the present invention. The difference from the prior art in Example 1 is that after the cord fabrics are vacuum-absorbed, they are firstly dried by ultraviolet light. Double-sided irradiation, and then dried by high-energy electronic drying equipment, so it can be seen that the drying process is completed under irradiation conditions.

Embodiment 3

[0028] As for the above-mentioned embodiment 2, this embodiment adopts a method based on ultraviolet light and high-energy electron irradiation to cure the cord fabric impregnated with radiation-curable impregnating glue, wherein the selection range of the voltage is between 200 and 600KV, and the radiation absorption The selection range of dose is between 10~100KGy. In this embodiment, the electron beam irradiation voltage is adjusted to 200KV, the radiation absorption dose is 20KGy, and the impregnating glue is cured.

[0029] The radiation-curable impregnating glue of this embodiment is composed of 100 parts of polyisocyanate, 70 parts of acrylate, 10 parts of vinyl ether monomer and 0.2 part of photoinitiator in parts by weight. Among them, polyisocyanate can be selected between 100~300 parts, acrylate can be selected between 70~240 parts, vinyl ether monomer can be selected between 10~40 parts, and photoinitiator can be selected between 0.2~240 parts. Choose between 30 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com