An electrode net tensioning device for preparing upper and lower electrode conductive concrete slabs

A technology of conductive concrete slabs and tensioning devices, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult positioning of the electrode grid, uneven resistance of the middle conductive layer, uneven current, etc., to solve the problems of easy corrosion and construction technology Simple and convenient quality control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described in conjunction with the following examples.

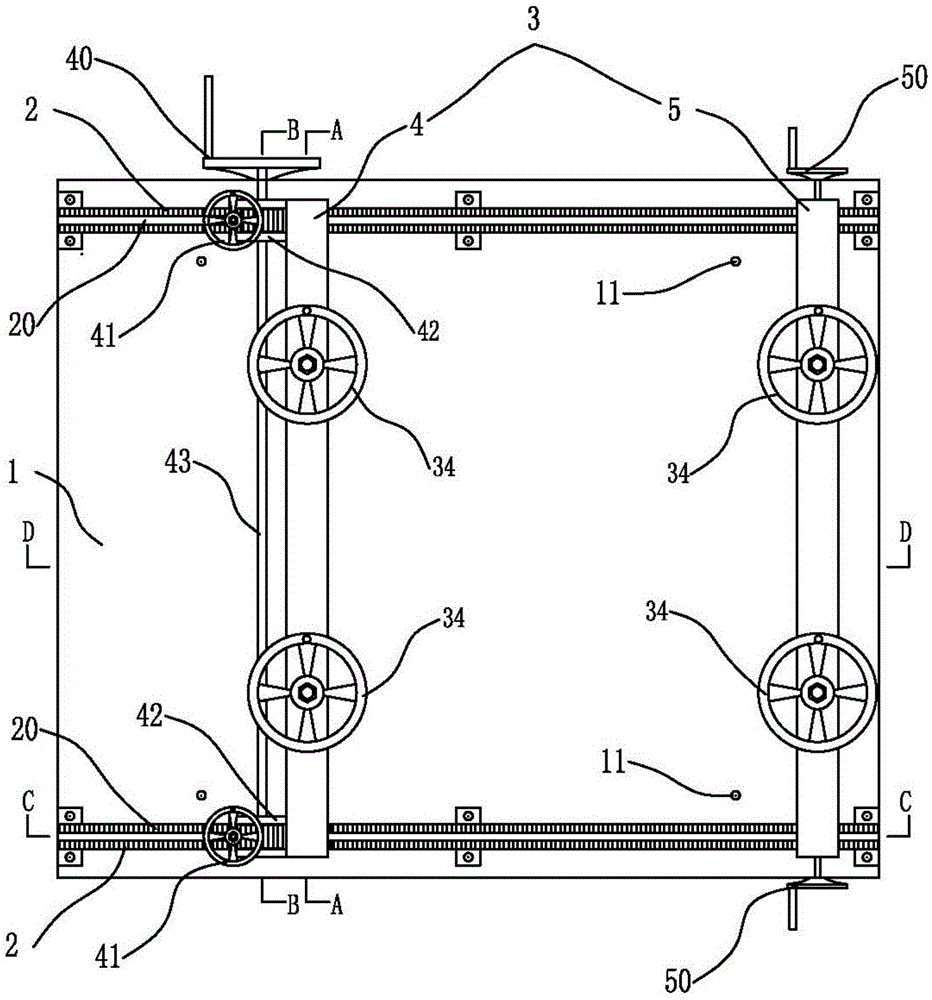

[0036] An electrode net tensioning device for preparing upper and lower electrode type conductive concrete slabs created by the present invention, such as Figure 1 to Figure 5 As shown, it includes a base 1 , two parallel racks 2 fixedly laid on the base 1 , and two pressure clamps 3 oppositely arranged along the direction of the two parallel racks 2 .

[0037] The base 1 is preferably a wooden base, and for strengthening the supporting strength of the base, it is preferable to arrange some reinforcing square wooden strips 10 in parallel on its bottom surface, see figure 2 and Figure 4 . If the base 1 is a square base, the reinforcing square wooden bar 10 is preferably arranged parallel to the edge of the base. Reinforcement square wood bar 10 directly adopts iron nail to be close to the bottom surface of base 1 and nails tightly. A specific position on the base 1 is also pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com