A production process of hidden plastic edge wood floor

A production process and floor technology, applied in the direction of wood processing utensils, manufacturing tools, etc., can solve problems such as the decline of the waterproof performance of wooden floors, and achieve the effect of improving the waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

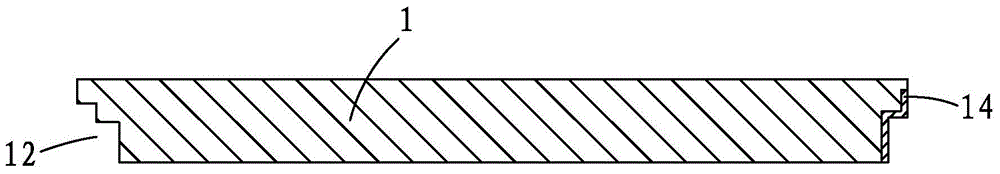

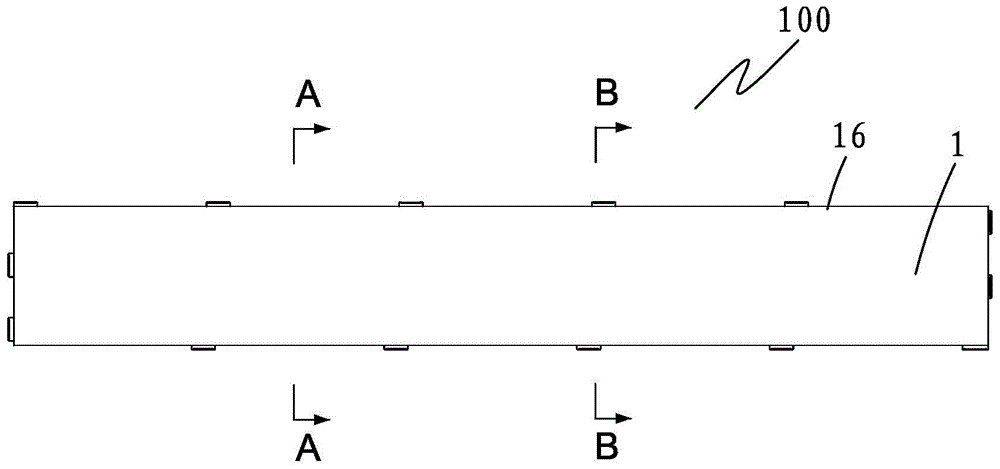

[0023] Such as Figure 1 to Figure 5 Shown, the production technology of hidden type plastic edge wooden floor of the present invention comprises

[0024] Step 10, opening the board: opening the board according to the predetermined size to form the solid wood floor blank 1;

[0025] Step 20, open double-layer T-shaped grooves: set double-layer T-shaped grooves 12 on the four sides of the solid wood floor blank 1, so that the four sides of the solid wood floor blank 1 are all retracted one by one from top to bottom to form a three-layer ladder. The width of the ladder is the largest;

[0026] Step 30, injection molding edge banding: put the solid wood floor blank 1 into the cavity 2 of the injection molding edge banding machine, use the injection molding edge banding machine to form a plastic edge 14 on the double-layer T-shaped groove 12, and the plastic edge 14 is hidden on the uppermost layer The back of the ladder.

[0027] Another example Figure 6 and Figure 7 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com