Automatic processing equipment for small-diameter copper tubes with inner and outer cones and thin-walled circles

An automatic processing and thin-walled technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of uneven wall thickness, large axial resistance, short service life, etc., to improve wall thickness uniformity and low cost , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

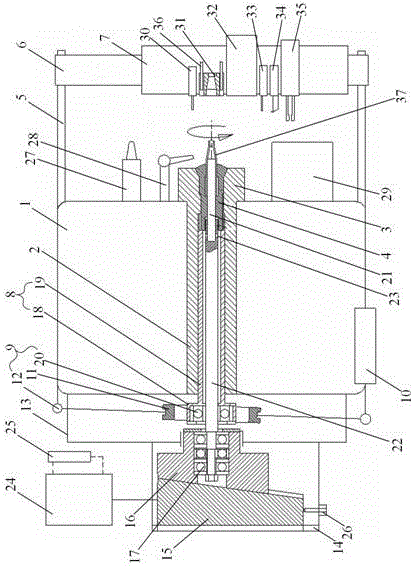

[0041] The automatic processing equipment of small-diameter copper tubes with inner and outer cones and thin-walled circles of the present invention will be described in detail below in conjunction with the drawings and embodiments of the description:

[0042] Such as figure 1 As shown, an automatic processing equipment for small-diameter copper pipes with inner and outer cones and thin-walled circles, including supporting mechanisms, spinning pipe fittings inner cone actuators, integral spinner molds for spinning pipe fittings outer cones, mold cleaning rotary head, and processing thin-walled round pipes Cutting tool and loading and unloading mechanism;

[0043] The supporting mechanism includes a headstock 1, a cylinder 10 installed below the headstock 1, two parallel transverse guide rails 5 are installed on the right side of the headstock 1, the longitudinal guide rails 6 are installed on the transverse guide rails 5, and the servo motor drives the slide table 7 Installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com