High-precision deep hole combination drill and machining method thereof

A processing method and technology of compound drilling, applied in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of cumbersome operation, difficult size control, poor fatigue resistance in the processing process, etc. Processing cycle, reducing processing difficulty, and solving the effect of poor fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The processing method of the above-mentioned high-precision deep hole compound drill is as follows:

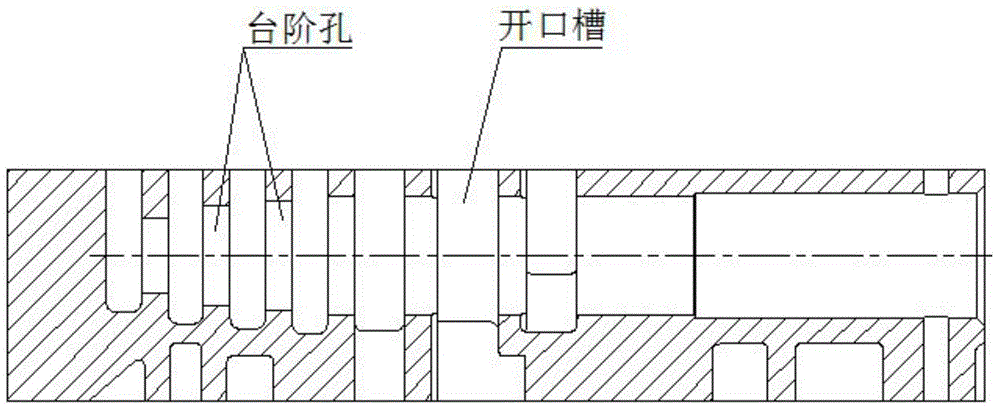

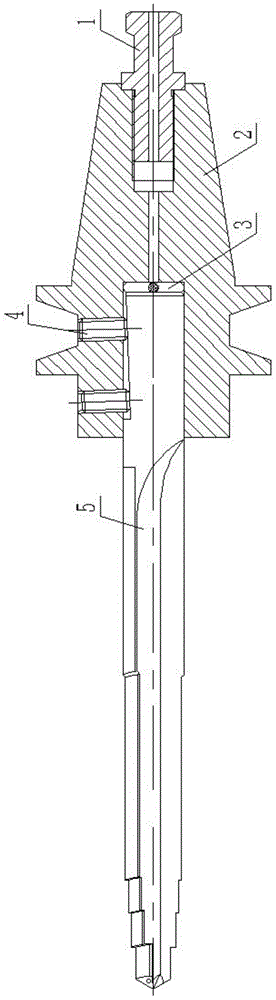

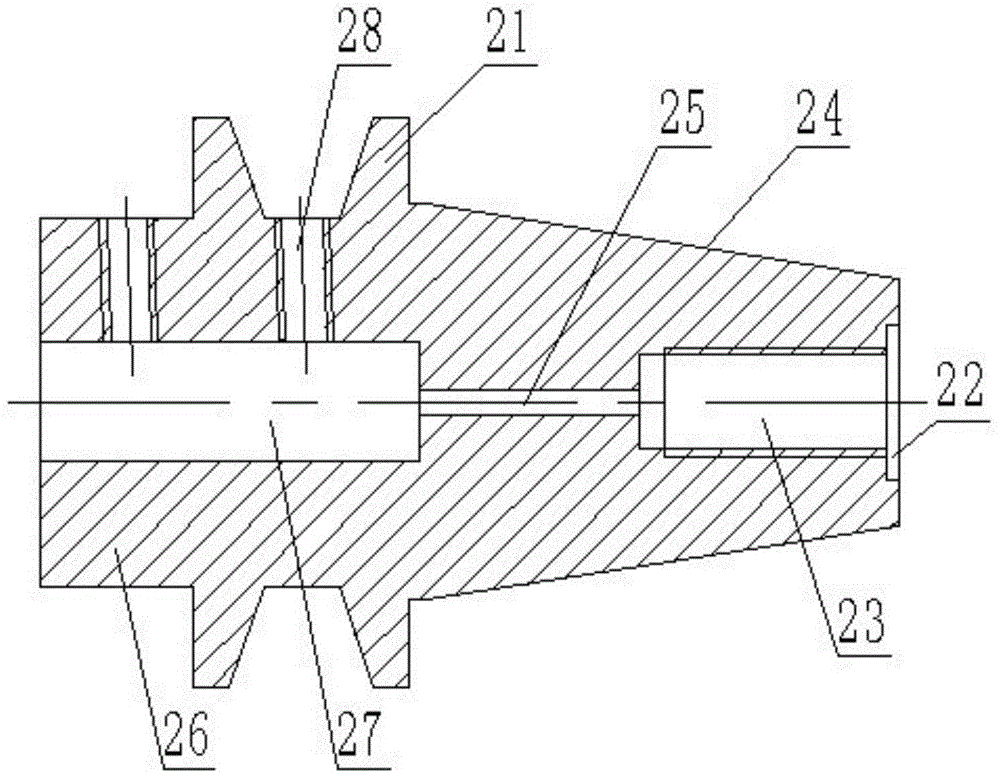

[0041]After the heat treatment, the knife handle 2 is machined with a precision numerical control lathe to produce a flange 21, a mounting hole 27, a pressing hole 28, a through hole 25, a connecting hole 23, a counterbore 22 and a tapered section 24, wherein the tapered section 24 remains The unilateral margin is 0.08mm, and then it is ground with a precision cylindrical grinder to ensure that the fit of the tapered section 24 after being tightened in the machine tool spindle reaches 85%; the straight groove drill 5 uses a standard hard alloy round The area bar is used as the blank, the liquid hole 55 is processed by laser ablation, and the remaining dimensions are ground by a precision cylindrical grinder and a universal CNC tool grinder. Among them, the radial dimension of the cutting edge 51 has a margin of 0.02mm on both sides; high precision After the deep hole co...

Embodiment 2

[0043] The processing method of the above-mentioned high-precision deep hole compound drill is as follows:

[0044] After the heat treatment, the knife handle 2 is machined with a precision numerical control lathe to produce a flange 21, a mounting hole 27, a pressing hole 28, a through hole 25, a connecting hole 23, a counterbore 22 and a tapered section 24, wherein the tapered section 24 remains The unilateral margin is 0.09mm, and then it is ground with a precision cylindrical grinder to ensure that the fit of the tapered section 24 after being tightened in the machine tool spindle reaches 83%; the straight groove drill 5 uses a standard hard alloy round The area bar is used as the blank, the liquid hole 55 is processed by laser ablation, and the remaining dimensions are ground by a precision cylindrical grinder and a universal CNC tool grinder. Among them, the radial dimension of the cutting edge 51 has a margin of 0.03mm on both sides; high precision After the deep hole c...

Embodiment 3

[0046] The processing method of the above-mentioned high-precision deep hole compound drill is as follows:

[0047] After the heat treatment, the knife handle 2 is machined with a precision numerical control lathe to produce a flange 21, a mounting hole 27, a pressing hole 28, a through hole 25, a connecting hole 23, a counterbore 22 and a tapered section 24, wherein the tapered section 24 remains The unilateral margin is 0.10mm, and then it is ground with a precision cylindrical grinder to ensure that the fit of the tapered section 24 after being tightened in the machine tool spindle reaches 89%; the straight groove drill 5 uses a standard hard alloy round The area bar is used as the blank, the liquid hole 55 is processed by laser ablation, and the remaining dimensions are ground by a precision cylindrical grinder and a universal CNC tool grinder. Among them, the radial dimension of the cutting edge 51 has a margin of 0.04mm on both sides; high precision After the deep hole c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com